Abstract

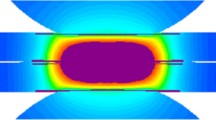

More galvanized steels are being used in auto body assembly to improve safety and fuel efficiency of automobiles. However, spot welding these materials will result in a short electrode life due to serious and inconsistent electrode wear. Electrode radial wear during the electrode life test is the main factor leading to unacceptable nugget size. This paper firstly studied the feedback characteristics of servo guns to detect electrode axial wear online based on the developed system of an integrated servo gun with robot. Then a mathematical model of a spherical electrode was established to evaluate radial wear by detecting axial wear online at different electrode wear stages. The model was verified by experiments for welding different galvanized steels. It was shown that evaluation results of the model agreed well with the experiment results. The model revealed that a smaller radius of electrode face at beginning welds would result in a higher electrode wear rate. The method of evaluating electrode wear online based on the model also offered a guidance to determine the suitable time for tip dressing in real production.

Similar content being viewed by others

References

R Holiday, Parker JD, Williams NT (1996) Relative contribution of electrode tip growth mechanisms in spot welding zinc coated steels. Weld World 37(4):186–193

Chatterjee KL, Waddell W (1996) Electrode wear during spot welding of coated steels. Weld Mat Fabr 3(3):110–114

Bracun D, Diaci J, Polajnar I, Mozina J (2002) Using laser profilometry to monitor electrode wear during resistance spot welding. Sci Technol Weld Join 7(5):294–298

Li W (2005) Modeling and on-line estimation of electrode wear in resistance spot welding. J Manuf Sci Eng 127(11):709–717

Tang H (2000) Machine mechanical characteristics and their influences on resistance spot welding quality. Philosophy Doctor Paper of Michigan University

ABB (2002) ABB flexible automation for savings with servo guns. ABB Corporation 12(9)

Zhang XQ, Chen GL, Zhang YS (2005) Character analysis of servo gun technology in resistance spot welding process. Transactions of the China Welding Institution 26(6):60–64

Wu KC (1968) Electrode indentation criterion for resistance spot welding. Weld J 5(10):472-s–478-s

Fukumoto S, Lum I (2003) Effects of electrode degradation on electrode life in resistance spot welding of aluminum alloy 5182. Welding Journal, 9(11):307-s–312-s

Lu F, Dong P (1999) Model for Estimating electrode face diameter during resistance spot welding. Sci Technol Weld Join 4(5):285–289

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X.Q., Chen, G.L. & Zhang, Y.S. On-line evaluation of electrode wear by servo gun in resistance spot welding. Int J Adv Manuf Technol 36, 681–688 (2008). https://doi.org/10.1007/s00170-006-0885-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0885-8