Abstract

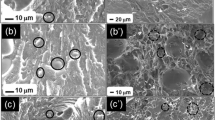

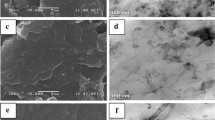

Polyacrylonitrile-co-poly(methylmethacrylate)/multiwalled carbon nanotubes (PAN-co-PMMA/MWCNTs) nanocomposites were synthesized by an in situ emulsifier-free polymerization method with variable percentages of functionalized carbon nanotube (f-MWCNT). MWCNTs were functionalized with concentrated H2SO4 and HNO3 with a continuous sonication process. Chemical interaction of f-MWCNT with the copolymer was studied by UV-visible spectroscopy. Fourier transform infrared spectroscopy proved the interaction of f-MWCNT with the PAN-co-PMMA copolymer matrix. The structural interaction of f-MWCNT with copolymer matrix was investigated by X-ray diffraction study. The dispersion and morphology of the f-MWCNT in the copolymer matrix were studied by scanning electron microscopy and high-resolution transmission electron microscopy. It was noticed that the f-MWCNTs were uniformly dispersed within the copolymer matrix. The thermal property of the PAN-co-PMMA/f-MWCNT nanocomposite was analyzed by thermogravimetric analysis. It was noticed that the thermal stability of the PAN-co-PMMA/f-MWCNT nanocomposite was more than that of the virgin copolymer matrix. When the electrical conductivity property of the synthesized nanocomposite was measured, it was noticed that the better dispersion of f-MWCNT in the non-conductive PAN-co-PMMA copolymer matrix made the PAN-co-PMMA/f-MWCNT nanocomposites conductive. From the measurement of gas barrier properties of synthesized nanocomposites, it was assumed that the well-dispersed f-MWCNT in the copolymer matrix creates the huddles for penetration of oxygen gas. It was noticed that the oxygen permeability of the PAN-co-PMMA/f-MWCNT nanocomposite was reduced by five times as compared to that of the neat PAN-co-PMMA copolymer matrix. The PAN-co-PMMA/f-MWCNT nanocomposites with higher thermal stability and reduced oxygen permeability properties may be suitable for application as conducting packaging materials.

Similar content being viewed by others

References

Park SJ, Cho MS, Lim ST, Choi HJ, John MS (2005) Electrorheology of multiwalled carbon nanotube/poly(methyl methacrylate) nanocomposites. Macromol Rapid Commun 26:1563–1566

Iijima S, Ichihashi T (1993) Single-shell carbon nanotubes of 1-nm diameter. Nature 363:603–605

Wong EW, Sheehan PE, Lieber CM (1997) Nanobeam mechanisms: elasticity, strength and toughness of nanorods and nanotubes. Science 277:1971–1975

Pirlot C, Willems I, Fonseca A, Nagy JB, Delhalle J (2002) Preparation and characterization of carbon nanotube/polyacrylonitrile composites. J Adv Eng Mater 4:109–114

Zhang WD, Phang IY, Shen L, Chou SY, Liu TX (2004) Polymer nanocomposites using urchin-shaped carbon nanotube-silica hybrids as reinforcing fillers. Macromol Rapid Commun 25:1860–1864

Petrov P, Lou XD, Pagnoulle C, Jerome C, Calberg C, Jerome R (2004) Functionalization of multiwalled carbon nanotubes by electro grafting of polyacrylonitrile. Macromol Rapid Commun 25:987–990

Wang B, Wang H, Hong B, Zhang Y (2005) Fibers from multiwalled carbon nanotube/polyacrylonitrile composites. Polym J 37:376–379

Min HS, Kang DW, Lee DY, Kim DW (2002) Gel polymer electrolytes prepared with porous membranes based on an acrylonitrile/methylmethacrylate copolymer. J Polym Sci Part B: Polym Phys 40:1496–1502

Patra SK, Swain SK (2012) Effect of organoclays on thermal, mechanical and oxygen barrier properties of poly(methylmethacrylate-co-acrylonitrile)/clay nanocomposites. Polym Compos 33:796–802

Swain SK, Prusty G, Das R (2012) Sonochemical compatibility of polyvinyl alcohol/polyacrylic acid blend in aqueous solution. J Macromol Sci Part B Phys 51:580–589

Choi BK, Kim YW, Shin HK (2000) Ionic conduction in PEO-PAN blends polymer electrolytes. Electrochim Acta 45:1371–1374

Sahoo PK, Rana PK, Sahoo A, Debsarkar NL, Swain SK (2003) Characterization and properties of chemically modified Corchorus capsularis jute fiber via pulping and grafting: infrared, thermogravimetric analysis, differential scanning electron microscopy, X-ray diffraction, biodegradation and super absorbency. J Polym Sci Part A: Polym Chem 41:2696–2703

Gavelin P, Jannasch P, Wesslen B (2001) Amphiphilic polymer gel electrolytes. I. Preparation of gels based on poly(ethylene oxide) graft copolymers containing different ionophobic groups. J Polym Sci Part A: Polym Chem 39:2223–2232

Latif F, Aziz M, Katun N, Ali AM, Yahya MZ (2006) The role and impact of rubber in poly(methylmethacrylate)/lithium triflate electrolyte. J Power Sources 159:1401–1404

Kao HM, Chang PC, Chao SW, Lee CH (2006) Li NMR, ionic conductivity and self-diffusion coefficients of lithium ion and solvent of plasticized organic-inorganic hybrid electrolyte based on PPG-PEG-PPG diamine and alkoxy silanes. Electrochim Acta 52:1015–1027

Ajayan PM, Shadler LS, Giannaris C, Rubio A (2000) Single walled carbon nanotube-polymer composites: strength and weakness. Adv Mater 12:750–753

Haggenmuller R, Gonmas HH, Rinzler AG, Fischer JE, Winey KI (2000) Aligned single-wall carbon nanotubes in composites by melt processing methods. Chem Phys Lett 330:219–225

Jin Z, Pramoda KP, Goh SH, Xu G (2002) Poly(vinylidene fluoride)-assisted melt blending of multiwalled carbon nanotube/poly(methylmethacrylate) composites. Mater Res Bull 37:271–278

Ginic-Markvic M, Matsons JG, Simon GP, Fredericks PM (2006) Synthesis of new polyaniline/nanotube composites using ultrasonically initiated emulsion polymerization. Chem Mater 18:6258–6265

Kang X, Ma W, Zhang HL, Xu ZG, Guo Y, Xiong Y (2008) Vinyl-carbon nanotubes for composite polymer materials. J Appl Polym Sci 110:1915–1920

Lee CH, Liu JY, Chen SL, Wang YZ (2007) Miscibility and properties of acid treated multiwalled carbon nanotubes/polyurethane nanocomposites. Polym J 39:138–146

Kim S, Choi H, Hong S (2007) Bulk polystyrene in the presence of multiwalled carbon nanotubes. Colloid Polym Sci 285:593–598

Liang YH, Wang CC, Chen CY (2007) Conductivity and characterization of plasticized polymer electrolyte based on (polyacrylonitrile-b-polyethylene glycol) copolymer. J Power Sources 172:886–892

Schmidt RH, Kinloch IA, Burgess AN, Windle AN (2007) The effect of aggregation on the electrical conductivity of spin-coated polymer/carbon nanotube composite films. Langmuir 23:5707–5712

Sabio MM, Gonzalez MT, Reinoso FR, Escribano AS (1996) Effect of steam and carbon dioxide activation in the micro pore size distribution of activated carbon. Carbon 34:505–509

Addoun A, Dentzer J, Ehrburger P (2002) Porosity of carbons obtained by chemical activation: effect of the nature of the alkaline carbonates. Carbon 40:1140–1143

Prusty G, Swain SK (2011) Synthesis and characterization of PAN/graphite nanocomposites. Polym Compos 32:1336–1342

Sohi NJS, Bhadra S, Khastgir D (2011) The effect of different carbon fillers on the electrical conductivity of ethylene vinyl acetate copolymer-based composites and the applicability of different conductivity models. Carbon 49:1349–1361

Sahoo PK, Samal S, Swain SK, Rana PK (2008) Synthesis of poly(butylacrylate)/layer silicate nanocomposites fire retardant. Eur Polym J 44:3522–3528

Zhao X, Zhang Q, Chen D (2010) Enhanced mechanical properties of graphene-based poly(vinyl alcohol) composites. Macromolecules 43:2357–2363

Prusty G, Swain SK (2012) Dispersion of expanded graphite as nanoplatelets in a copolymer matrix and its effect on thermal, conductive and permeable properties. New Carbon Mater 27:271–277

Bauhofer W, Kovacs JZ (2009) A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos Sci Technol 69:1486–1498

Winey KI, Kashiwagi T, Mu MF (2007) Improving electrical conductivity and thermal properties of polymers by the addition of carbon nanotubes as fillers. MRS Bull 32:348–353

Acknowledgments

The authors are thankful to BRNS, DAE, and the Government of India for providing financial support under grant OM no. 2008/20/37/5/BRNS/1936.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pradhan, A.K., Swain, S.K. Synthesis and characterization of poly(acrylonitrile-co-methylmethacrylate) nanocomposites reinforced by functionalized multiwalled carbon nanotubes. Iran Polym J 22, 369–376 (2013). https://doi.org/10.1007/s13726-013-0136-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-013-0136-4