Abstract

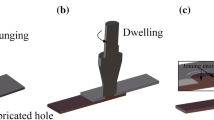

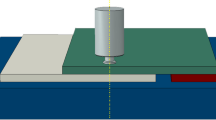

Friction stir brazing of 5-mm-thick Al and Cu plates in simple lap and stepped lap joint configurations was carried out in air as a modified process for friction stir lap welding of dissimilar metals, in which a pin-free tool and a 0.1-mm-thick Zn braze foil were used to eliminate both pin wear and keyhole and to achieve interface mixing by a metallurgical reaction route instead of vertical plastic mixing, respectively. The microstructure distribution features of friction stir brazing were characterized and compared with traditional furnace brazing to confirm the metallurgical advantages of the new process. For traditional furnace brazing, poor wettability at the Al side for lower brazing temperature or solidification cracking within too thick solidified microstructure (~150 µm) at higher brazing temperature was found. For friction stir brazing, oxide film removal could be achieved well in air without flux by rapid dissolution of the base metals into the molten braze; both solidified microstructure and solidification cracking could be eliminated by extruding excessive liquid phase out of the interface.

Similar content being viewed by others

References

C.Z. Xia, Y.J. Li, U.A. Puchkov, S.A. Gerasimovb, J. Wang, Crack analysis near vacuum brazing interface of Cu/Al dissimilar materials using Al–Si brazing alloy. Mater. Sci. Technol. 25(3), 383–387 (2009)

C. Berlanga-Labari, A. Albistur-Goni, P. Balerdi-Azpilicueta, M. Gutierrez-Peinado, J. Fernandez-Carrasquilla, Study and selection of the most appropriate filler materials for an Al/Cu brazing joint in cooling circuits. Mater. Manuf. Process. 26(2), 236–241 (2011)

J. Luo, G.J. Zhao, X.J. Wang, Y. Sun, Characteristics and thermodynamics analysis of oxyacetylene flame brazing joint of Cu/Al tubes. J. Chongqing Univ. 34(5), 31–35 (2011)

K. Shinozaki, K. Koyama, Development of Al/Cu dissimilar brazing joint controlled form of intermetallic compound. Mater. Sci. Forum. 539–543(Part 4), 4075–4080 (2007)

F. Ji, S.B. Xue, J. Lou, Y. Lou, S.Q. Wang, Microstructure and properties of Cu/Al joints brazed with Zn–Al filler metals. Trans. Nonferrous Met. Soc. China 22(2), 281–287 (2012)

A. Elrefaey, M. Takahashi, K. Ikeuchi, Preliminary investigation of friction stir welding aluminium/copper lap joints. Weld. World 49(3–4), 93–101 (2005)

A. Abdollah-Zadeh, T. Saeid, B. Sazgari, Microstructural and mechanical properties of friction stir welded aluminum/copper lap joints. J. Alloys Compd. 460, 535–538 (2008)

T. Saeid, A. Abdollah-Zadeh, B. Sazgari, Weldability and mechanical properties of dissimilar aluminum–copper lap joints made by friction stir welding. J. Alloys Compd. 490, 652–655 (2010)

P. Xue, B.L. Xiao, D. Wang, Z.Y. Ma, Achieving high property friction stir welded aluminium/copper lap joint at low heat input. Sci. Technol. Weld. Join. 16(8), 657–661 (2011)

M. Akbari, R. Abdi-Behnagh, Dissimilar friction-stir lap joining of 5083 aluminum alloy to CuZn34 brass. Metall. Mater. Trans. B 43(10), 1177–1186 (2012)

H. Bisadi, A. Tavakoli, M.T. Sangsaraki, K.T. Sangsaraki, The influences of rotational and welding speeds on microstructures and mechanical properties of friction stir welded Al5083 and commercially pure copper sheets lap joints. Mater. Des. 43, 80–88 (2013)

Y.C. Chen, T. Komazaki, T. Tsumura, K. Nakata, Role of zinc coat in friction stir lap welding Al and zinc coated steel. Mater. Sci. Eng. A 24(1), 33–39 (2008)

R.T. Lee, C.T. Liu, Y.C. Chiou, H.L. Chen, Effect of nickel coating on the shear strength of FSW lap joint between Ni–Cu alloy and steel. J. Mater. Process. Technol. 213, 69–74 (2013)

V. Firouzdor, S. Kou, Al-to-Cu friction stir lap welding. Metall. Mater. Trans. A 43(1), 303–315 (2012)

G. Zhang, W. Su, J. Zhang, Z. Wei, Friction stir brazing, a novel process for fabricating Al/steel layered composite and for dissimilar joining of Al to steel. Metall. Mater. Trans. A 42, 2850–2861 (2011)

G.F. Zhang, W. Su, J. Zhang, J.X. Zhang, Visual observation of effect of tilting tool on forging action during FSW of aluminium sheet. Sci. Technol. Weld. Join. 16(1), 87–91 (2011)

G.F. Zhang, W. Su, J. Zhang, Z.X. Wei, J.X. Zhang, Effects of shoulder on interfacial bonding during friction stir lap welding of aluminum thin sheets using tool without pin. Trans. Nonferrous Met. Soc. China 20, 2223–2228 (2010)

W.F. Gale, D.A. Butts, Transient liquid phase bonding. Sci. Technol. Weld. Join. 9(4), 283–301 (2004)

V. Soundararajan, E. Yarrapareddy, R. Kovacevic, Investigation of the friction stir lap welding of aluminum alloys AA 5182 and AA 6022. J. Mater. Eng. Perform. 16(4), 477–484 (2007)

L.E. Murr, A review of FSW research on dissimilar metal and alloy systems. J. Mater. Eng. Perform. 19(8), 1071–1089 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, GF., Zhang, K., Guo, Y. et al. A Comparative Study of Friction Stir Brazing and Furnace Brazing of Dissimilar Metal Al and Cu Plates. Metallogr. Microstruct. Anal. 3, 272–280 (2014). https://doi.org/10.1007/s13632-014-0146-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-014-0146-4