Abstract

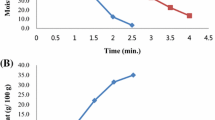

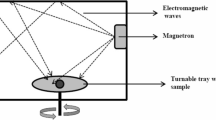

Since snacks high in fats are known to be a significant source of fat and energy intake, these have been put in high dietary restraint category. Therefore, an attempt was made to process potato chips through microwave processing without incorporation of any oil in potato chips. Microwave processing of potato chips was done using microwave power varying from 180 to 600 W using constant sample size. Among eleven different drying models, Parabolic model was found to be the best fit through non-linear regression analysis to illustrate drying kinetics of potato chips. The structural, textural and colour attributes of microwaved potato chips were similar to commercial fried potato chips. It was found that at 600 W after 2.5–3.0 min of processing, potato chips gained the fracturability and crispiness index as that of commercial fried chips. Microwave processing was found suitable for processing of potato chips with low fat content (~3.09 vs 35.5 % in commercial preparation) and with acceptable sensory scores (≥7.6 on 9.0 point on hedonic scale vs 8.0 of control preparation).

Similar content being viewed by others

References

Aguilera JM, Castro L, Cadoche L (2004) Structure property relationships in starch amorphous model. In: Proceedings of the 14th international drying symposium, Sao Paulo, Brazil, pp. 1468–1472

Bai-Ngew S, Therdthai N, Dhamvithee P (2011) Characterization of microwave vacuum-dried durian chips. J Food Eng 104:114–122

Barbosa-Canovas GV, Vega-Mercado H (1996) Dehydration of foods, Ist edn. Chapman & Hall, New York

Corzo O, Bracho N, Pereira A, Vásquez A (2008) Weibull distribution for modelling air drying of coroba slices. LWT-Food Sci Technol 41:2023–2028

Dadali G, Apar DK, Ozbek B (2007) Color change kinetics of okra undergoing microwave drying. Dry Technol 25:925–937

Dak M, Prateek NK (2014) Effective moisture diffusivity of pomegranate arils undergoing microwave-vacuum drying. J of Food Eng 122:117–121

Garmakhany AD, Mirzaei HO, Nejad MK, Maghsuldlo Y (2008) Study of oil uptake and quality attributes of potato chips affected by hydrocolloids. Eur J Lipid Sci Technol 110:1045–1049

Giri SK, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78(2):512–521

Henderson SM, Pabis S (1961) Grain drying theory I: temperature effect on drying coefficient. J Agricul Res Eng 6:169–174

http://www.dnaindia.com/health/report (2015) India has third-highest number of obese people, reveals study. Accessed 09 Apr 2015 (Dainik Bhaskar dated 13/04/2015, p 10)

http://www.google.co.in/patents/US3402049. Process for preparing low fat potato chips. Accessed 27 Feb 2014

Karaaslan SN, Tuncer IK (2008) Development of a drying model for combined microwave-fan-assisted convection drying of spinach. Biosyst Eng 100(1):44–52

Kharaisheh MAM, Cooper TJR, Magee TRA (1995) Investigation and modeling of combined microwave and air drying. Food Bioprod Process 73:121–126

Kingsly ARP, Singh DB (2007) Drying kinetics of pomegranate arils. J Food Eng 79:741–744

Krishna Murthy TP, Harish A, Rashmi M, Mathew Blessy B, Monisha J (2014) Effect of blanching and microwave power on drying behavior of green peas. Res J Eng Sci 3(4):10–18

Kumar D, Ezekiel R (2005) Changes in sugar content and processing quality of potatoes during storage and reconditioning. J Food Sci Technol 42:400–404

Kumar P, Pandey SK, Singh SV, Kumar D (2007) Irrigation requirements of chipping potato cultivars under West Central Indian plains. Potato J 34:193–198

Larmond E (1977) Laboratory methods for sensory evaluation of foods. Canada Dept Agric Ottawa, Ottawa 1637

Lewis WK (1921) The rate of drying of solid materials. J Ind Eng 13:427–443

Marwaha RS, Kumar D, Singh SV, Pandey SK (2008) Influence of blanching of slices of potato varieties on chipping quality. J Food Sci Technol 45:364–367

Marwaha RS, Pandey SK, Kumar D, Singh SV, Kumar P (2010) Potato processing scenario in India: industrial constraints, future projections, challenges ahead and remedies—a review. J Food Sci Technol 47(2):137–156

Mohapatra D, Rao PS (2005) A thin layer drying model of parboiled wheat. J Food Eng 66:513–518

Page G (1949) Factors influencing the maximum rates of air drying shelled corn in thin layers. MSc Thesis, Purdue University, Indiana, USA

Pandey A, Singh G (2011) Development of reduced sugar soy containing compound chocolate and its storage study. J Food Sci Technol 48(1):76–82

Pardeshi I, Burbade RG, Khod RN (2013) Cost effective drying for high quality tender wheatgrass powder. J Food Res Technol 1(1):1–10

Park YW (1987) Effect of freezing, thawing, drying, and cooking on carotene retention in carrots, broccoli and spinach. J Food Sci 52:1022–1025

Pimpaporn P, Devahastin S, Chiewchan N (2007) Effects of combined pretreatments on drying kinetics and quality of potato chips undergoing low-pressure superheated steam drying. J Food Eng 81:318–329

Ranganna S (2007) Handbook of analysis and quality control for fruit and vegetable products, 2nd edn. Tata McGraw Hill, New Delhi

Rautela S, Chopra CS, Pandey A, Raghav M (2009) Physico-chemical characteristics and chipping performance of organic potatoes (Solanum tuberosum). In: Proceedings: National conference on Engineering for food & Bio-processing, pp. 312–316

Scaman CH, Durance TD (2005) Emerging technologies for food processing. Elsevier Academic Press, London, p 768

Sharma GP, Prasad S (2004) Effective diffusivity of garlic cloves undergoing microwave convective drying. J Food Eng 65:609–617

Shiroma C, Rodrigues-Saona L (2007) Rapid quality control of potato chips using near and mid infrared spectroscopy. Poster presentation. http://kb.osu.edu/dspace/handle/1811/24730 Accessed 23 May 2015

Singh B, Kaul HN, Ezekiel R (2004) Effect of Isopropyl-N (3-chlorophenyl) carbamate (CIPC) dusting on potatoes during non-refrigerated storage: sprout suppression and residues. J Food Sci Technol 41:550–553

Talburt WF, Smith O (1987) Potato processing, 2nd edn. Mack Printing Company, Eastern Pennsylvania, p 588

Tong CH, Lund DB (1990) Effective moisture diffusivity in porous materials as a function of temperature and moisture content. Biotechnol Prog 6(1):67–75

Vega-Gálvez A, Miranda M, Díaz LP, Lopez L, Rodriguez K, Di Scala K (2010) Effective moisture diffusivity determination and mathematical modelling of the drying curves of the olive-waste cake. Bioresour Technol 101:7265–7270

Verma LR, Bucklin RA, Endan JB, Wratten FT (1985) Effects of drying air parameters on rice drying models. Trans ASAE 28:296–301

Vinaixaa M, Vergaraa A, Durana C, Llobet E, Badiaa C (2005) Fast detection of rancidity in potato crisps using e-noses based on mass spectrometry or gas sensors. Sens Actuators B 106:67–75

Wang CY, Singh RP (1978) A single layer drying equation for rough rice. ASAE Paper No: 78-3001

Wang Z, Sun J, Chen F, Liao X, Hu X (2007) Mathematical modeling on thin layer microwave drying of apple pomace with and without hot air pre-drying. J Food Eng 80(2):536–544

Acknowledgments

Authors are grateful to Director, ICAR-IARI for extending the facilities for conducting this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joshi, A., Rudra, S.G., Sagar, V.R. et al. Development of low fat potato chips through microwave processing. J Food Sci Technol 53, 3296–3303 (2016). https://doi.org/10.1007/s13197-016-2304-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2304-y