Abstract

Fermentation of batter is an integral part of the preparation of jilebi, a traditional ready-to-eat sweet product of Indian sub-continent. The flowability and pourability of batter are crucial for forming jilebi strands during frying. Flowability and pourability have been determined from simulation studies based on the movement of batter on an inclined surface and the exit from an orifice, respectively; simple gadgets have been designed to determine these two characteristics along with providing the definitions. Response surface experimental design consisting of moisture content (50–65%), amount of added curd (0–10%) and time of fermentation (0–24 h) has been employed. The response functions are pH, flowability and pourability. Strong interaction effects of added curd and time of fermentation on the response functions have been observed. An increase in added curd and time of fermentation decreases pH in a curvilinear manner as both linear and quadratic effects are significant (p ≤ 0.01). Moisture content has a non-significant effect on pH but markedly affects the flowability and pourability of batter. Flowability and pourability decreases when there is an increase in consistency index or apparent viscosity.

Similar content being viewed by others

References

AOAC (1980) Official methods of analysis, 13th edn. Association of Official Analytical Chemists, Washington, DC

Berry SK (1992) Role of air in foods. Indian Food Ind 11(2):40–46

Chakkaravarthi A, Punil Kumar HN, Bhattacharya S (2009a) Jilebi—An Indian traditional sweet: attributes, manufacturing practices and scope for large scale production. Indian Food Ind 28(2):30–36

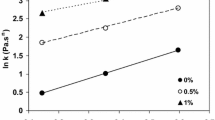

Chakkaravarthi A, Punil Kumar HN, Bhattacharya S (2009b) Jilebi :1. Effect of moisture content, curd addition and fermentation time on the rheological properties of dispersions. J Food Sci Technol 46:543–548

Chitale SR (2000) Commercialization of Indian traditional foods: Jeelebi, Ladoo and Bakervadi. In: Proc. International Conference on Traditional Foods. Central Food Technological Research Institute, Mysore, India, p 331

Khuri AI, Cornell JA (1989) Response surfaces: designs and analyses. Marcel Dekker, Inc., New York

Myers RH (1971) Response surface methodology. Allyn and Bacon, Inc., Boston

Rati Rao E, Vijayendra SVN, Varadaraj MC (2006) Fermentation biotechnology of traditional foods of the Indian subcontinent. In: Shetty K, Paliyath G, Pometto A, Levin RE (eds) Food biotechnology, 2nd edition, Ch 3.18. CRC Press (Taylor & Francis Group), Boca Raton, pp 1718–1753

Acknowledgement

The grant from CSIR, India to conduct the present research work under Network Project (NWP 002) is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chakkaravarthi, A., Kumar, H.N.P. & Bhattacharya, S. Jilebi 2: Flowability, pourability and pH of batter as affected by fermentation. J Food Sci Technol 50, 293–300 (2013). https://doi.org/10.1007/s13197-011-0326-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0326-z