Abstract

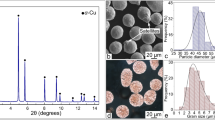

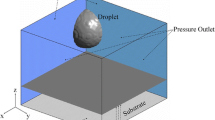

Plasma sprayed coatings are built up by the accumulation of splats formed by the impacting, spreading and solidifying of molten droplets on the substrate. A three-dimensional computational model including heat transfer and solidification is established to simulate the formation process of a single splat using the computational fluid dynamics (CFD) software, FLUENT. The fluid flow and energy equations are discretized and solved according to typical finite volume method on an unstructured grid. A volume of fluid (VOF) tracking algorithm is used to track the droplet flow with free surface. In order to understand the splat formation mechanism, the process of splat formation caused by impacting and spreading of a molten nickel droplet on a polished mild steel surface is simulated. On this basis, the simulations of impact of a molten droplet on substrate with different conditions including the surface morphology, thermal conductivity, initial temperature of the substrate and the thermal contact resistance are presented. The results clearly show the effect of those parameters on the shape of the final splat and splash behaviors.

Similar content being viewed by others

References

Fauchais P. Understanding plasma spraying [J]. Journal of Physics D: Applied Physics, 2004, 37(9): 86–108.

Fauchais P, Fukumoto M, Vardelle A, et al. Knowledge concerning splat formation: An invited review [J]. Journal of Thermal Spray Technology, 2004, 13(2): 337–360.

Armster S Q, Delplanque J-P, Rein M, et al. Thermo-fluid mechanisms controlling droplet based materials processes [J]. International Materials Reviews, 2002, 47(4): 265–301.

Chandra S, Fauchais P. Formation of solid splats during thermal spray deposition [J]. Journal of Thermal Spray Technology, 2009, 18(2): 148–180.

Lahmar Y, Vardelle A, Fauchais P, et al. Modelling the nucleation process in alumina lamellae deposited on a steel substrate [J]. Journal of Thermal Sciences, 2009, 11(2): 1–7.

Pasandideh M, Pershin V, Chandra S, et al. Splat shapes in a thermal spray coating process: simulations and experiments [J]. Journal of Thermal Spray Technology, 2002, 11(2): 206–217.

Parizi H B, Rosenzweig L, Mostaghimi J, et al. Numerical simulation of droplet impact on patterned surfaces [J]. Journal of Thermal Spray Technology, 2007, 16(5–6): 713–721.

Fang Jian-cheng, Wang Li, Xu Wen-ji, et al. Numerical simulation of splat formation dynamics in plasma spray forming [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: S41–S45.

Bussmann M, Mostaghimi J, Chandra S. On a three-dimensional volume tracking model of droplet impact [J]. Physics of Fluids, 1999, 11(4): 1406–1417.

Bussmann M, Chandra S, Mostaghimi J. Modeling the splashing of a droplet impacting a solid surface [J]. Physics of Fluids, 2000, 12(12): 3121–3132.

Pasandideh M, Chandra S, Mostaghimi J. A threedimensional model of droplet impact and solidification [J]. International Journal of Heat and Mass Transfer, 2002, 45(11): 2229–2242.

Kang C W, Ng H W. Splat morphology and spreading behavior due to oblique impact of droplets onto substrates in plasma spray coating process [J]. Surface and Coatings Technology, 2006, 200(18–19): 5462–5477.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, Cw., Li, Q. Three-dimensional numerical simulation of splat formation on substrates in plasma spraying. J. Shanghai Jiaotong Univ. (Sci.) 16, 347–351 (2011). https://doi.org/10.1007/s12204-011-1158-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-011-1158-8