Abstract

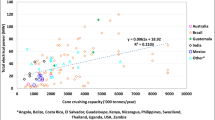

We use bottom-up conservation supply curves (CSC) to analyze the cost-effectiveness of various energy efficiency measures for the Thai sugar industry. The study was conducted in two parts. First, energy efficiency measures were identified from data collected from five leading Thai sugar mills (four recommended by the Office of the Cane and Sugar Board and the last being owned by the world’s sixth largest sugar producer). The CSC indicates that 15 energy efficiency measures are cost-effective and 2 measures are not cost-effective. Next, we surveyed nine other Thai sugar factories to consider the average potential energy saving and the factors which might influence implementation of such energy efficiency measures. The average energy saving currently being achieved by the nine factories is 77 %, which indicates that 23 % of the energy saving potential is not being achieved. The key driving forces indicated by the nine factories were the potential to reduce energy costs and creating a good “green” image for the company. The main barriers were investment attitudes towards high investment cost and the low commercial value of bagasse. In relation to investment attitudes, it was found that Thai sugar mills focus on sugar production capacity and lack interest in energy efficiency measures, especially those which require a high investment cost. This is partly because the industry produces low commercial of bagasse that can be used to generate electricity, so that energy is not seen as an important cost of production.

Similar content being viewed by others

References

Bocci, E., Carlo, D. A., & Marcelo, D. (2009). Power plant perspectives for sugarcane mills from sugarcane mills. Energy, 34, 689–698.

DEDE (Department of Alternative Energy Development and Efficiency) (2012). Thailand Energy Statistic. Retrieved on June 30, 2013 from http://www.dede.go.th/dede/index.php.

Ensinas, A. V., Nebra, S. A., Lozano, M. A., & Serra, L. M. (2007). Analysis of process steam demand reduction and electricity generation in sugar and ethanol production from sugarcane. Energy Conversion and Management, 48, 2978–2987.

Golove, W. H., & Eto, J. H. (1996). Market barriers to energy efficiency: a critical reappraisal of the rationale for public policies to promote energy efficiency. Lawrence Berkeley National Laboratory, LBL-38059. Retrieved on December 27, 2012 from http://www.eetd.lbl.gov/ea/emp/reports/38059.pdf.

Hasanbeig, A., Menke, C., & Pont, P. D. (2010). Barriers to energy efficiency improvement and decision-making behavior in Thai industry. Energy Efficiency, 3, 33–52.

Hasanbeigi, A., McKane,A. (2010c). Motor systems efficiency supply curves, Retrieved on January 12, 2012 from http://www.aceee.org/conferences/2011/ssi/informal/descriptionshttp.

Hasanbeigi, A., Menke, C., & Therdyothin, A. (2010). The use of conservation supply curves in energy policy and economic analysis: the case study of Thai cement industry. Energy Policy, 38, 392–405.

Meier, A.K. (1982). Supply curves of conserved energy. Ph.D. thesis, University of California, Lawrence Berkeley Laboratory Retrieved on June 30, 2012 from http://www.repositories.cdlib.org/lbnl/LBL-14686/S.

NESDB (National Economic and Social Development Board) (2013). Gross domestic product 2011. Retrieved on January 9, 2013 from http://www.nesdb.go.th

Nguyen, T. L. T., Hermansen, J. E., & Sagisaka, M. (2009). Fossil energy savings potential of sugar cane bio-energy systems. Applied Energy, 86, 132–139.

OCSB (Office of the Cane and Sugar Board) (2007). In-depth study energy efficiency improvement for Thai sugar industries, Faculty of Engineering Chulalongkorn University report.

Pilot Plant Development and Training Institute, King Mongkut’s University of Technology Thonburi, Bangkok, Thailand: (2011). Final report, feasibility study on the development of efficient electricity and thermal improvement of the sugar industry, submitted to Energy Policy and Planning Office, Ministry of Energy.

Rohdin, P., Thollander, P., & Solding, P. (2007). Barriers to and drivers for energy efficiency in the Swedish foundry industry. Energy Policy, 35(1), 672–677.

Sattari, S., Avami, A., Farahandpour, B. (2007). Energy conservation opportunities: sugar industry in Iran, Proceedings of the WSEAS Int. Present at Conference on Energy Planning, Energy Saving, Environmental Education, Arcachon.

Siemers, W. (2009). Greenhouse gas balance for electricity production from biomass resource in Thailand. Present at World Renewable Energy Congress 2009-Asia, the 3rd International Conference on Sustainable Energy and Environment (SEE 2009), Bangkok.

Sorrell, S. (2003). Making the link: climate policy and the reform of the UK construction industry. Energy Policy, 31, 865–878.

Thollander, P., & Ottosson, M. (2008). An energy efficient Swedish pulp and paper industry—exploring barriers to and driving forces for cost-effective energy efficiency investments. Energy Efficiency, 1, 21–34.

Acknowledgments

The financial support provided by the Center for Energy Technology and Environment through the Joint Graduate School of Energy and Environment (JGSEE) is gratefully acknowledged. The cooperation of the OCSB (Office of the Cane and Sugar Board), the Pilot Plant Development and Training Institute, King Mongkut’s University of Technology Thonburi, and various sugar mills in providing information and assistance are also deeply appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sathitbun-anan, S., Fungtammasan, B., Barz, M. et al. An analysis of the cost-effectiveness of energy efficiency measures and factors affecting their implementation: a case study of Thai sugar industry. Energy Efficiency 8, 141–153 (2015). https://doi.org/10.1007/s12053-014-9281-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-014-9281-7