Abstract

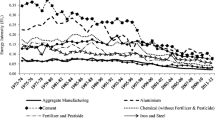

The Swedish pulp and paper industry accounts for half of industrial final energy use in Sweden and 2.3 % in EU-27. On the basis of a disaggregated set of physical production data, a Logarithmic Mean Divisia Index decomposition method is applied to disentangle the influence from activity, structure and energy efficiency improvement (EEI) on its fuel, electricity and primary energy use. An extended analysis tracks the fossil energy use and carbon dioxide (CO2) emissions to discern past and present developments of industrial decarbonisation. In 1984–2011, the total production output increased by 49 %, whereas growth in primary energy use was limited to 26 %. Compared with an activity-based scenario, 50 PJ of primary energy use has been avoided through EEI and 6 PJ through structural change. The production has become oriented towards more electricity-intensive but less fuel-intensive segments. The electricity use EEI was negligible until year 2000 but sizeable thereafter as it started to outpace the counteracting impact from structural change. Results are consistent with previous bottom-up evaluations, and the policy context is further elaborated in a discussion about the role of relevant energy and climate policies in facilitating the enhanced EEI observed over the last decade.

Similar content being viewed by others

Notes

Available statistics does not provide capacity utilisation rates at sub-sector level. For the Swedish manufacturing industry it was 91 % (2007) and from levels of 75–80 % (2009) it recovered to 88 % (2011) (SCB 2013). An estimated 3 % decrease for PPI is supported by data on production output and capacity (SFIF 2013; Wiberg and Forslund 2012).

Recovered fibre pulp has an exceptionally low specific final fuel use in 1984 compared with later survey years (see Appendix). This category has been excluded to avoid distortion of the weighted average for the pulp grades.

Chemical pulp mills generate electricity from spent liquor in recovery boilers and back pressure turbines while thermomechanical pulp and paper mills use mainly solid biofuel boilers and back pressure turbines. Exhaust lower-pressure steam is used for drying pulp and paper. The allocation procedures in Wiberg (1985–2008) and Wiberg and Forslund (2012) imply that annual average fuel-to-electricity conversion factors are in the range of 1.15–1.25. Thus, the savings from combined heat and power are allocated to the electricity generation (Phylipsen et al. 1998).

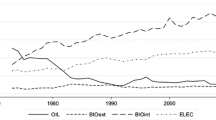

The Swedish PPI uses some 20 different fuels. On the product level these fuels are merged into the main categories: external fuel oil, external other, internal spent liquor, internal bark and internal other. The large category “external other” represent a mix of many non-fossil but also fossil fuels (Wiberg and Forslund 2012).

Compared to final fuel use, total fuel use includes fuels for internal electricity generation (see Figure 3). Thus, the numbers are somewhat higher, e.g. 166 vs. 156 PJ (1984) and 217 vs. 195 PJ (2007).

This estimate is based on an emission factor of 0.036 kg CO2/kWh purchased electricity, being representative for the Swedish grid electricity mix in 2008 (Gode et al. 2011). Emissions factors for fossil fuels are as follows: fuel oil (76.2 kg CO2/GJ), coal (90.7 kg CO2/GJ), LPG (65.1 kg CO2/GJ) and natural gas (56.5 kg CO2/GJ).

PFE firms must: conduct energy audits; have certified energy management systems (ISO 50001); have procedures for energy efficient procurement and project planning; undertake and report electricity savings actions. Firms are exempted from the minimum tax on industrial electricity use of the EU energy tax directive (0.5 Euro/MWh) and are required to achieve electricity savings at a level expected had the tax been in place (Stenqvist and Nilsson 2012). PFE will expire in 2014 according to EU state-aid rules for environmental protection.

It corresponds to 2 % of Sweden’s total electricity use and the annual generation capacity of the country’s oldest operating nuclear reactor.

References

Ang, B. W. (1995). Decomposition methodology in industrial energy demand analysis. Energy, 20(11), 1081–1095.

Ang, B. W. (2004). Decomposition analysis for policymaking in energy: which is the preferred method? Energy Policy, 32(9), 1131–1139.

Ang, B. W. (2005). The LMDI approach to decomposition analysis: a practical guide. Energy Policy, 33(7), 867–871.

Ang, B. W., & Liu, N. (2007). Energy decomposition analysis: IEA model versus other methods. Energy Policy, 35(3), 1426–1432.

Ang, B. W., & Zhang, F. Q. (2000). A survey of index decomposition analysis in energy and environmental studies. Energy, 25(12), 1149–1176.

CEPI. (2011). The forest fibre industry—2050 roadmap to a low-carbon bio-economy. Brussels: Confederation of European Paper Industries.

CEPI. (2013). Key statistics 2012—European pulp and paper industry. Brussels: Confederation of European Paper Industries.

Danske Bank (2013). Skog & Ekonomi—Nyheter från Danske Bank. No 2, May 2013.

Diakoulaki, D., & Mandaraka, M. (2007). Decomposition analysis for assessing the progress in decoupling industrial growth from CO2 emissions in the EU manufacturing sector. Energy Economics, 29(4), 636–664.

EC (2006). Directive 2006/32/EC of the European parliament and of the council of 5 April 2006 on energy end-use efficiency and energy services and repealing Council Directive 93/76/EEC. OJ L114. Luxembourg: Publications Office of the European Union.

EC. (2010). Europe 2020—a strategy for smart, sustainable and inclusive growth. COM (2010) 2020 final. Brussels: European Commission.

EC (2012). Directive 2012/27/EU of the European parliament and of the council of 25 October 2012 on energy efficiency, amending Directives 2009/125/EC and 2010/30/EU and repealing Directives 2004/8/EC and 2006/32/EC. OJ L315. Luxembourg: Publications Office of the European Union.

Ericsson, K., Nilsson, L. J., & Nilsson, M. (2011). New energy strategies in the Swedish pulp and paper industry—the role of national and EU climate and energy policies. Energy Policy, 39(3), 1439–1449.

Eurostat (2013). “Consumption of energy”. Available at http://epp.eurostat.ec.europa.eu/statistics_explained/index.php/Consumption_of_energy. Accessed 15 October 2013

Farla, J., Blok, K., & Schipper, L. (1997). Energy efficiency developments in the pulp and paper industry: a cross-country comparison using physical production data. Energy Policy, 25(7–9), 745–758.

Gode, J., Martinsson, F., Hagberg, L., Öman, A., Höglund, J., & Palm, D. (2011). Miljöfaktaboken 2011—estimated emission factors for fuels, electricity, heat and transport in Sweden. Stockholm: Värmeforsk Service AB.

Greening, L. A., Boyd, G., & Roop, J. M. (2007). Modeling of industrial energy consumption: an introduction and context. Energy Economics, 29(4), 599–608.

Gulbrandsen, L., & Stenqvist, C. (2013a). The limited effect of EU emissions trading on corporate climate strategies: comparison of a Swedish and a Norwegian pulp and paper company. Energy Policy, 56(2013), 516–525.

Gulbrandsen, L., & Stenqvist, C. (2013b). Pulp and paper industry. In J. B. Skjӕrseth & P. O. Eikeland (Eds.), Corporate responses to EU emissions trading: resistance, innovation or responsibility? (pp. 127–164). Farnham: Ashgate.

Haaker, A. (2013). Nu byggs Södras nya pelletsfabrik i Värö. Bioenergi, 1, 22–25.

Henriksson, E., Söderholm, P., & Wårell, L. (2012). Industrial electricity demand and energy efficiency policy: the role of price changes and private R&D in the Swedish pulp and paper industry. Energy Policy, 47(2012), 437–446.

IEA. (2007). Tracking industrial energy efficiency and CO 2 emissions—in support of the G8 plan of action. Paris: International Energy Agency.

IEA. (2010). Energy technology perspective 2010—scenarios and strategies to 2050. Paris: International Energy Agency.

IEA. (2013). Redrawing the energy-climate map: world energy outlook special report. Paris: International Energy Agency.

IIP and IEA (Ed.). (2012). Energy management programmes for industry: gaining through saving. Washington, DC: Institute for Industrial Productivity.

IPCC. (2007). Climate change 2007: synthesis report. In Core Writing Team, R. K. Pachauri, & A. Reisinger (Eds.), Contribution of working groups I, II and III to the fourth assessment report of the Intergovernmental Panel on climate Change. Geneva: IPCC.

Isacson, Ö., Cordi, I., Ewetz, J., & Wernelind, Å. (1987). Industrins energianvändning—Analys av de förändringar som ägt rum under perioden 1970–84 [Industrial energy use—analysis of changes in the period 1970–84]. Stockholm: STU-information.

Karltorp, K., & Sandén, B. A. (2012). Explaining regime destabilisation in the pulp and paper industry. Environmental Innovation and Societal Transitions, 2(2012), 66–81.

Lindmark, M., Bergquist, A., & Andersson, L. F. (2011). Energy transition, carbon dioxide reduction and output growth in the Swedish pulp and paper industry: 1973–2006. Energy Policy, 39(9), 5449–5456.

Ojala, J., Lamberg, J., Ahola, A., & Melander, A. (2006). The ephemera of success: strategy, structure and performance in the forestry industries. In J. Lamberg, J. Näsi, J. Ojala, & P. Sajasalo (Eds.), The evolution of competitive strategies in global forestry industries: comparative perspectives (pp. 257–286). The Netherlands: Springer.

Ottosson, M., & Magnusson, T. (2013). Socio-technical regimes and heterogeneous capabilities: the Swedish pulp and paper industry’s response to energy policies. Technology Analysis & Strategic Management, 25(4), 355–368.

Phylipsen, G. J. M., Blok, K., & Worrell, E. (1998). Handbook on international comparisons of energy efficiency in the manufacturing industry. Utrecht: Department of Science, Technology and Society, Utrecht University.

SCB (2013). ”Industrins kapacitetsutnyttjande”. Available at http://www.scb.se/Pages/SSD/SSD_SelectVariables____340487.aspx?px_tableid=ssd_extern%3aIndKaputnSNI07Kv&rxid=0c0507d5-aaf9-4468-8c9f-a984bbe2125f. Accessed 30 June 2013

SEA. (2009). Resultat från PFEs första programperiod. Eskilstuna: Swedish Energy Agency.

SEA. (2012). Energiläget i siffror 2012. Eskilstuna: Swedish Energy Agency.

SEA (2013a). “Resultat period 2”. Available at http://energimyndigheten.se/sv/Foretag/Energieffektivisering-i-foretag/PFE/Resultat-och-utvardering/Resultat-period-2/. Accessed 20 October 2013

SEA (2013b). “Resultat period 1: Slutredovisning övriga åtgärder”. Available at http://energimyndigheten.se/sv/Foretag/Energieffektivisering-i-foretag/PFE/Resultat-och-utvardering/Resultat-fran-programmet/. Accessed 20 October 2013

SFA. (1987). Statistical yearbook of forestry 1987. Jönköping: National Board of Forestry.

SFA. (2012). Swedish statistical yearbook of forestry 2012. Jönköping: National Board of Forestry.

SFIF (2013). “Reports”. Available at http://miljodatabas.skogsindustrierna.org/si/main/reportselect.aspx?l1=report. Accessed 16 August 2013

Stenqvist, C. (2013). Industrial energy efficiency improvement—the role of policy and evaluation. Doctoral dissertation. Lund: Lund University.

Stenqvist, C., & Nilsson, L. J. (2012). Energy efficiency in energy-intensive industries—an evaluation of the Swedish voluntary agreement PFE. Energy Efficiency, 5(2), 225–241.

Thomas, S. (2009). Measuring and reporting energy savings for the energy services directive—how it can be done. Wuppertal: Wuppertal Institute.

Wade, J., Guertler, P., Croft, D., & Sunderland, L. (2011). National energy efficiency and energy saving targets. Stockholm: European Council for an Energy Efficient Economy.

Wiberg, R. (1974). Energiförbrukning i massa- och pappersindustrin 1973 [Energy use in pulp- and paper industry 1973]. Stockholm: Svenska Cellulosa- och Pappersbruksföreningen.

Wiberg, R. (1980). Energiförbrukning i massa- och pappersindustrin 1979 [Energy use in the pulp- and paper industry 1979]. Stockholm: Svenska Cellulosa- och Pappersbruksföreningen.

Wiberg, R. (1985). Energiförbrukning i massa- och pappersindustrin 1984 [Energy use in the pulp- and paper industry 1984]. Stockholm: Svenska Cellulosa- och Pappersbruksföreningen.

Wiberg, R. (1989). Energiförbrukning i massa- och pappersindustrin 1988 [Energy use in the pulp- and paper industry 1988]. Stockholm: Skogsindustrierna.

Wiberg, R. (1995). Energiförbrukning i massa- och pappersindustrin 1994 [Energy use in the pulp- and paper industry 1994]. Stockholm: Skogsindustrierna.

Wiberg, R. (2001). Energiförbrukning i massa- och pappersindustrin 2000 [Energy use in the pulp- and paper industry 2000]. Stockholm: Skogsindustrierna.

Wiberg, R. (2008). Energiförbrukning i massa- och pappersindustrin 2007 [Energy use in the pulp- and paper industry 2007]. Stockholm: Skogsindustrierna.

Wiberg, R., & Forslund, M. (2012). Energiförbrukning i massa- och pappersindustrin 2011 [Energy use in the pulp- and paper industry 2011]. Stockholm: Skogsindustrierna.

Worrell, E., Bernstein, L., Roy, J., Price, L., & Hamisch, J. (2009). Industrial energy efficiency and climate change mitigation. Energy Efficiency, 2(2), 109–123.

Acknowledgements

This work has been funded by the Swedish Energy Agency’s research programme General Energy Systems Studies (AES).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Stenqvist, C. Trends in energy performance of the Swedish pulp and paper industry: 1984–2011. Energy Efficiency 8, 1–17 (2015). https://doi.org/10.1007/s12053-014-9276-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-014-9276-4