Abstract

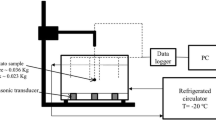

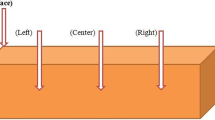

Effective heat transfer coefficients were measured using an aluminum test body and compared with the results obtained from a Gnielinski correlation for air-blast freezing of a fruit pulp model in multilayer boxes, with the internal airflow through rectangular ducts and the hydraulic diameter as characteristic dimensions. The quantities of products inside the boxes were varied, and the inlet air velocities and temperature profiles during freezing were measured. The inlet air velocities were applied in dimensionless Gnielinski correlations to estimate the local heat transfer coefficient values. The experimental and predicted heat transfer coefficient values were used to determine an average convective heat transfer coefficient weighted by the heat transfer area. The results from this methodology were used in an analytically derived procedure for freezing-time estimates and then compared with experimental results. The average effective heat transfer coefficient underestimated freezing times and demonstrated a higher level of accuracy than the Gnielinski correlation when applied to boxes containing smaller product amounts. For experiments with greater quantity of products, the use of average heat transfer coefficients from the Gnielinski correlation yielded errors lower than 20%. Based on boundary layer theory, the Gnielinski correlation can be used to explain the isotherm behaviors observed during freezing. Many of the results satisfy the standards of accuracy used in engineering, and the procedure does not require extra computational effort.

Similar content being viewed by others

Abbreviations

- A :

-

area, m2

- Bi s :

-

Biot number = h2L/k

- C f :

-

friction factor

- Cp :

-

specific heat Jkg−1 °C−1

- Cm :

-

layer number

- D 1 :

-

width of polyethylene bags m

- D 2 :

-

length of polyethylene bags m

- D 3 :

-

height of polyethylene bags m

- D h :

-

channel hydraulic diameter \( {D_h} = \frac{{2{H_c}W}}{{\left( {{H_c} + W} \right)}}\left( {\text{m}} \right) \)

- e :

-

error between experimental and predicted values

- E AN :

-

equivalent heat transfer dimensionality analytically derived

- \( {\overline h_i} \) :

-

local convective heat transfer coefficient Wm−2 °C−1

- \( heff \) :

-

effective heat transfer coefficient Wm−2 °C−1

- H :

-

test section height m

- k :

-

total area defined in equation (16), m2

- K :

-

thermal conductivity Wm−1 °C−1

- L :

-

surface length of the test section m; duct length m

- Nu :

-

Nusselt number

- \( {\overline {Nu}_i} \) :

-

local Nusselt number, Eqs. (6 and 7)

- \( {\overline {Nu}_{{_{\infty }}}} \) :

-

theoretical average Nusselt number, Eqs. (4 and 6)

- Pr :

-

Prandtl number

- Re Dh :

-

Reynolds number based on the hydraulic diameter

- SD :

-

standard deviation

- S 2 :

-

cooling coefficient defined in Eq. (2)

- t :

-

time (s min, h)

- t exp :

-

experimental freezing time h

- t f :

-

freezing time h

- t f,slab :

-

freezing time of an infinite slab with the same basic dimension h

- \( \overline u \) :

-

average air velocity ms−1

- \( \hat{V} \) :

-

estimator of variance

- W :

-

width m

- x :

-

distance from entrance of the test section m

- z :

-

distance from wall of the test section m

- Z n , Z m :

-

roots of transcendental equation of type C = αtanα

- Z nm :

-

defined by the Eq. (13).

- βi :

-

ratio of dimension to characteristic dimension i = 1, 2

- ΔHi :

-

change in relative enthalpy content (J/m3) i = 1 (pre-cooling) and i = 2 (freezing and tempering)

- ΔTi :

-

change in temperature (K) i = 1 (pre-cooling) and i = 2 (freezing and tempering)

- ρ :

-

density (kgm−3)

- Al :

-

aluminum

- air :

-

air

- c :

-

channel

- corr :

-

Gnielinski correlation

- i :

-

initial

- pred :

-

predicted

- exp :

-

experimental

References

Barbin, D. F., Neves Filho, L. C., & Silveira Junior, V. (2010). Convective heat transfer coefficients evaluation for a portable forced air tunnel. Applied Thermal Engineering, 30, 229–233.

Carslaw, H. S., & Jaeger, J. C. (1959). Conduction of heat in solids (2nd ed.). UK: Oxford University Press.

Cleland, A. C. (1990). Food refrigeration process. Analysis, design and simulation. London: Elsevier Applied Science.

Cleland, D. J., Cleland, A. C., & Jones, R. S. (1994). Collection of accurate experimental data testing the performance of simple methods for food freezing time prediction. Journal of Food Process Engineering, 17, 93–119.

Delgado, A. E., & Sun, D.-W. (2001). Heat and mass transfer models for predicting freezing process—a review. Journal of Food Engineering, 47, 157–174.

Hagen, K. D. (1999). Heat transfer with applications. Upper Saddle River: Prentice-Hall, Inc.

Hossain, M. M., Cleland, D. J., & Cleland, A. C. (1992). Prediction of freezing and thawing times for foods of regular multi-dimensional shape by using an analytically derived geometric factor. International Journal of Refrigeration, 15(4), 227–234.

Karwa, R., Solanki, S. C., & Saini, J. S. (1999). Heat transfer coefficient and friction factor correlations for the transitional flow regime in rib-roughened rectangular ducts. International Journal of Heat and Mass Transfer, 42, 1597–1615.

Kondjoyan, A. (2006). A review on surface heat and mass transfer coefficients during air chilling and storage of food products. International Journal of Refrigeration, 29, 863–875.

Kondjoyan, A., Daudin, J. D., & Bimbenet, J. J. (1993). Heat and mass transfer coefficients at the surface of elliptical cylinders placed in a turbulent air flow. Journal of Food Engineering, 20, 339–367.

Kurtbaş, I. (2008). The effect of different inlet conditions of air in a rectangular channel on convection heat transfer: Turbulence flow. Experimental Thermal and Fluid Science, 33, 140–152.

Leblanc, D. I., Kok, R., & Timbers, G. E. (1990). Freezing of a parallelepiped food product. Part 1. Experimental determination. International Journal of Refrigeration, 13, 371–378.

Mannaperuma, J. D., Singh, R. P., & Reid, D. S. (1994a). Effective surface heat transfer coefficients encountered in air blast freezing of whole chicken and chicken parts, individually and in packages. International Journal of Refrigeration, 17(4), 263–272.

Mannaperuma, J. D., Singh, R. P., & Reid, D. S. (1994b). Effective surface heat transfer coefficients encountered in air blast freezing of single plastic wrapped whole turkey. International Journal of Refrigeration, 17(4), 273–280.

Pham, Q. T. (1986). Simplified equation for predicting the freezing time of foodstuffs. Journal of Food Technology, 21(6), 209–219.

Pham, Q. T., Trujillo, F. J., & McPhail, N. (2009). Finite element model for beef chilling using CFD-generated heat transfer coefficients. International Journal of Refrigeration, 32, 102–113.

Pham, Q. T., & Willix, J. (1987). Heat transfer coefficients in the air blast freezing of rows of cartons. In: Proceedings 17th Int. Congress of Refrigeration, 1987, 350–357.

Reno, M. J., Resende, J. V., Peres, A. P., Giarolla, T. M. O., & Prado, M. E. T. (2011). Heat transfer and energy consumption in the freezing of guava in large containers. Applied Thermal Engineering, 31, 545–555.

Remley, T. J., Abdel-Khalik, S. I., Jeter, S. M., Ghiaasiaan, S. M., & Dowling, M. F. (2001). Effect of non-uniform heat flux on wall friction and convection heat transfer coefficient in a trapezoidal channel. International Journal of Heat and Mass Transfer, 44, 2453–2459.

Resende, J. V., & Silveira, V., Jr. (2002). Medidas da condutividade térmica efetiva de modelos de polpas de frutas no estado congelado. Ciência e Tecnologia de Alimentos, 22(2), 177–183. doi:10.1590/S0101-20612002000200013.

Resende, J. V., Neves Filho, L. C., & Silveira, V., Jr. (2002). Coeficientes de transferência de calor efetivos no congelamento com ar forçado de modelos de polpas de frutas em caixas comerciais. Brazilian Journal of Food Technology, 5, 33–42. Available at: http://www.bjft.ital.sp.gov.br/artigos/html/busca/PDF/v5nu078a.pdf. Accessed 01 December 2011.

Salvadori, V. O., & Mascheroni, R. H. (1996). Freezing of strawberry pulp in large containers: experimental determination and prediction of freezing times. International Journal of Refrigeration, 19, 87–94.

Verboven, P., Flick, D., Nicolaï, B. M., & Alvarez, G. (2006). Modelling transport phenomena in refrigerated food bulks packages and stacks: basics and advances. International Journal of Refrigeration, 29, 985–997.

Welty, J. R., Wicks, C. E., & Wilson, R. E. (1984). Fundamentals of momentum, heat, and mass transfer (3rd ed.). New York: Wiley.

Zheng, L., Delgado, A., & Sun, D.-W. (2009). Surface heat transfer coefficients with and without phase change. In M. Shafiur Rhaman (Ed.), Food properties handbook (2nd ed.). Boca Raton: CRC Press, Taylor & Francis Group.

Acknowledgments

The authors wish to thank the Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG- Brazil), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq - Brazil) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES – Brazil) for financial support for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Resende, J.V., Prado, M.E.T. & Junior, V.S. Non-uniform Heat Transfer During Air-Blast Freezing of a Fruit Pulp Model in Multilayer Boxes. Food Bioprocess Technol 6, 146–159 (2013). https://doi.org/10.1007/s11947-011-0757-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0757-6