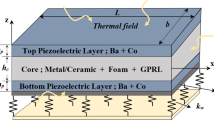

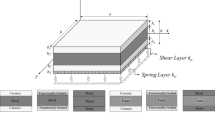

Piezoelectric materials, by virtue of their unique electromechanical characteristics, have been recognized for their potential utility in many applications as sensors and actuators. However, the sensing or actuating functionality of monolithic piezoelectric materials is generally limited. The composite approach to piezoelectric materials provides a unique opportunity to access a new design space with optimal mechanical and coupled characteristics. The properties of monolithic piezoelectric materials can be enhanced via the additive approach by adding two or more constituents to create several types of piezoelectric composites or via the subtractive approach by introducing controlled porosity in the matrix materials to create porous piezoelectric materials. Such porous piezoelectrics can be tailored to demonstrate improved signal-to-noise ratio, impedance matching, and sensitivity, and thus, they can be optimized for applications such as hydrophone devices. This article captures key results from the recent developments in the field of computational modeling of novel piezoelectric foam structures. It is demonstrated that the fundamental elastic, dielectric, and piezoelectric properties of piezoelectric foam are strongly dependent on the internal structure of the foams and the material volume fraction. The highest piezoelectric coupling constants and the highest acoustic impedance are obtained in the [3-3] interconnect-free piezoelectric foam structures, while the corresponding figures of merit for the [3-1] type long-porous structure are marginally higher. Among the [3-3] type foam structures, the sparsely-packed foam structures (with longer and thicker interconnects) display higher coupling constants and acoustic impedance as compared to closepacked foam structures (with shorter and thinner interconnects). The piezoelectric charge coefficients (d h), the hydrostatic voltage coefficients (g h), and the hydrostatic figures of merit (d hgh) are observed to be significantly higher for the [3-3] type piezoelectric foam structures as compared to the [3-1] type long-porous materials, and these can be enhanced significantly by modifying the aspect ratio of the porosity in the foam structures as well.

Similar content being viewed by others

References

R. Gerhard-Multhaupt, IEEE Trans. Dielectr. Electr. Insul. 9, 850 (2002).

C. Galassi, J. Eur. Ceram. Soc. 26, 2951 (2006).

R.E. Newnham, D.P. Skinner, and L.E. Cross, Mater. Res. Bull. 13, 525 (1978).

M.L. Dunn and M. Taya, Int. J. Solids Struct. 30, 161 (1993).

M.L. Dunn and M. Taya, Proc. R. Soc. Lond. A 443, 265 (1993).

R. Guinovart-Diaz, J. Bravo-Castillero, R. Rodrigues-Ramos, F.J. Sabina, and R. Martinez-Rosado, Mater. Lett. 48, 93 (2001).

R. Kar-Gupta and T.A. Venkatesh, Acta Mater. 55, 1093 (2007).

G. Hayward and J.A. Hossack, IEEE Trans. Ultrason. Ferroelectr. Freq. Control 38, 618 (1991).

H.E. Pettermann and S. Suresh, Int. J. Solids Struct. 37, 5447 (2000).

R. Kar-Gupta and T.A. Venkatesh, Acta Mater. 55, 1275 (2007).

C. Poizat and M. Sester, Comput. Mater. Sci. 16, 89 (1999).

D.P. Skinner, R.E. Newnham, and L.E. Cross, Mater. Res. Bull. 13, 599 (1978).

C. Richard, H.S. Lee, and D. Guyomar, Ultrasonics 42, 417 (2004).

R. Ramesh, D.C. Prasad, T.K. Vinod Kumar, L.A. Gavane, and R.M.R. Vishnubhatla, Ultrasonics 44, 341 (2006).

M.L. Dunn and M.J. Taya, Am. Ceram. Soc. 76, 1697 (1993).

H. Banno, Ceram. Bull. 66, 1332 (1987).

T.E. Gómez Alvarez-Arenas and F.M. Freijo, J. Acoust. Soc. Am. 100, 3104 (1996).

T.E. Gómez Alvarez-Arenas and F.M. Espinosa, Appl. Phys. Lett. 68, 263 (1996).

Y. Mikata, Int. J. Solids Struct. 38, 7045 (2001).

C.R. Bowen and V.Y. Topolov, Acta Mater. 51, 4965 (2003).

R. Kar-Gupta and T.A. Venkatesh, Acta Mater. 54, 4063 (2006).

R. Kar-Gupta and T.A. Venkatesh, Appl. Phys. Lett. 91, 062904 (2007).

S. Iyer and T.A. Venkatesh, Appl. Phys. Lett. 97, 072904 (2010).

S. Iyer and T.A. Venkatesh, J. Appl. Phys. 110, 034109 (2011).

R. Ramesh, H. Kara, and C.R. Bowen, Ultrasonics 43, 173 (2005).

U. Bast and W. Wersing, Ferroelectrics 94, 229 (1989).

K. Nagata, H. Igarashi, K. Okazaki, and R.C. Bradt, Jpn. J. Appl. Phys. 19, L37 (1980).

K. Hikita, K. Yamada, M. Nishioka, and M. Ono, Ferroelectrics 49, 265 (1983).

R.Y. Ting, Ferroelectrics 65, 11 (1985).

H. Kara, R. Ramesh, R. Stevens, and C.R. Bowen, IEEE Trans. Ultrason. Ferroelectr. Freq. Control 50, 289 (2003).

C.R. Bowen, A. Perry, A.C.F. Lewis, and H. Kara, J. Eur. Ceram. Soc. 24, 541 (2004).

Y.C. Chen and S. Wu, Ceram. Int. 30, 69 (2004).

D. Piazza, C. Capiani, and C. Galassi, J. Eur. Ceram. Soc. 25, 3075 (2005).

H.L. Zhang, L. Jing-Feng, and Z. Bo-Ping, Acta Mater. 55, 171 (2007).

K. Bounmchedda, M. Hamadi, and G. Fantozzi, J. Eur. Ceram. Soc. 27, 4169 (2007).

K. Li, X.-L. Gao, and G. Subhash, J. Mech. Phys. Solids 54, 783 (2006).

L.J. Gibson and M.F. Ashby, Cellular Solids: Structures and Properties (Cambridge, U.K.: Cambridge University Press, 1997).

R.M. Christensen, J. Mech. Phys. Solids 34, 563 (1986).

W.E. Warren and A.M. Kraynik, J. Appl. Mech. 55, 341 (1988).

W.E. Warren and A.M. Kraynik, J. Appl. Mech. 64, 787 (1997).

K. Li, X.-L. Gao, and A.K. Roy, Compos. B Eng. 36, 249 (2005).

H.X. Zhu, J.F. Knott, and N.J. Mills, J. Mech. Phys. Solids 45, 319 (1997).

H.X. Zhu, N.J. Mills, and J.F. Knott, J. Mech. Phys. Solids 45, 1875 (1997).

M.S. Roy, L.J. Ghisn, and B.A. Lerch, Int. J. Solids Struct. 45, 1754 (2008).

M.J. Silva, W.C. Hayes, and L.J. Gibson, Int. J. Mech. Sci. 37, 1161 (1995).

M.W.D. Van der Burg, V. Shulmeister, E. Van der Geissen, and R. Marissen, J. Cell. Plast. 33, 31 (1997).

H.X. Zhu, J.R. Hobdell, and A.H. Windle, Acta Mater. 48, 4893 (2000).

A.P. Robert and E.J. Garboczi, J. Mech. Phys. Solids 50, 33 (2002).

S. Sihn and A.K. Roy, J. Mech. Phys. Solids 52, 167 (2004).

S.M. Oppenheimer and D.C. Dunand, Acta Mater. 55, 3825 (2007).

S.A. Meguid, S.S. Cheon, and N. El-Abbasi, Finite Elem. Anal. Des. 38, 631 (2002).

S. Demiray, W. Becker, and J. Hohe, Int. J. Solids Struct. 44, 2093 (2007).

K.S. Challagulla and T.A. Venkatesh, Acta Mater. 60, 2111 (2012).

P.W. Bosse, K.S. Challagulla, and T.A. Venkatesh, Acta Mater. 60, 6464 (2012).

R. Kar-Gupta and T.A. Venkatesh, Acta Mater. 56, 3810 (2008).

Acknowledgements

This work has been supported by the Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Challagulla, K.S., Venkatesh, T.A. Computational Modeling of Piezoelectric Foams. JOM 65, 256–266 (2013). https://doi.org/10.1007/s11837-012-0515-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-012-0515-x