Abstract

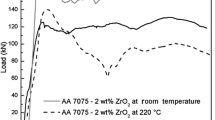

In this study, two powder consolidation techniques, equal channel angular pressing (ECAP) and extrusion, were utilized to consolidate attritioned aluminum powder and Al-5 vol.% nano-Al2O3 composite powder. The effect of ECAP and extrusion on consolidation behavior of composite powder and mechanical properties of subsequent compacts are presented. It is found that three passes of ECAP in tube at 200 °C is capable of consolidating the composite to 99.29% of its theoretical density whereas after hot extrusion of the composite the density reached to 98.5% of its theoretical density. Moreover, extrusion needs higher temperature and pressing load in comparison to the ECAP method. Hardness measurements show 1.7 and 1.2 times higher microhardness for the consolidated composite and pure aluminum after ECAP comparing with the extruded ones, respectively. Microstructural investigations and compression tests demonstrate stronger bonds between the particles after three passes of ECAP than the extrusion. Furthermore, the samples after three passes of ECAP show better wear resistance than the extruded ones.

Similar content being viewed by others

References

H.F. Lee, F. Boey, K.A. Khor, M.J. Tan, J. Gan, and N.L. Loh, The Production of Aluminum Alloy Composites Using a Cold Isostatic Press and Extrusion Approach, J. Mater. Process. Technol., 1992, 29, p 245–253

S.M. Zebarjad and S.A. Sajadi, Dependency of Physical and Mechanical Properties of Mechanical Alloyed Al-Al2O3 Composite on Milling Time, Mater. Des., 2007, 28, p 2113–2120

M. Tabandeh Khorshid, S.A. Jenabali Jahromi, and M.M. Moshksar, Mechanical Properties of Tri-Modal Al Matrix Composites Reinforced by Nano- and Submicron-Sized Al2O3 Particulates Developed by Wet Attrition Milling and Hot Extrusion, Mater. Des., 2010, 31, p 3880–3884

J.M. Torralba, C.E. da Costa, and F. Velasco, P/M Aluminum Matrix Composites: An Overview, J. Mater. Process. Technol., 2003, 133, p 203–206

B. Prabhu, C. Suryanarayana, L. An, and R. Vaidyanathan, Synthesis and Characterization of High Volume Fraction Al-Al2O3 Nanocomposite Powders by High Energy Milling, Mater. Sci. Eng. A, 2006, 425, p 192–200

A.A. Mazen and A.Y. Ahmed, Mechanical Behavior of Al-Al2O3 MMC Manufactured by PM Techniques Part I—Scheme I, Processing Parameters, J. Mat. Eng. Perform., 1998, 7, p 393–401

A.K. Mukhopadhyay, H.M. Flower, and T. Sheppard, Development of Mechanical Properties in AA 8090 Alloy Produced by Extrusion Processing, Mater. Sci. Technol., 1990, 6, p 461–468

H. Asanuma, M. Hirohashi, and O. Hayama, Fabrication of Complicated Shape Metal Matrix Composites by Combined Extrusion, Adv. Technol. Plast., 1990, 2, p 945–950

M.J. Tan and X. Zhang, Powder Metal Matrix Composites: Selection and Processing, Mater. Sci. Eng. A, 1998, 244, p 80–85

A. Parasiris, K.T. Hartwig, and M.N. Srinivasan, Formation/Consolidation of WC-Co Cermets by Simple Shear, Scripta Mater., 2000, 42, p 875–880

K. Xia and X. Wu, Back Pressure Equal Channel Angular Consolidation of Pure Al Particles, Scripta Mater., 2005, 53, p 1225–1229

K. Matsuki, T. Aida, T. Takeuchi, J. Kusui, and K. Yokoe, Microstructural Characteristics and Superplastic-Like Behavior in Aluminum Powder Alloy Consolidated by Equal Channel Angular Pressing, Acta Mater., 2000, 48, p 2625–2632

O.N. Senkov, D.B. Miracle, J.M. Scott, and S.V. Senkova, Equal Channel Angular Extrusion Compaction of Semi-Amorphous Al85Ni10Y2.5La2.5 Alloy Powder, J. Alloys. Compd., 2004, 365, p 126–133

J. Robertson, J.T. Im, I. Karaman, K.T. Hartwig, and I.E. Anderson, Consolidation of Amorphous Copper Based Powder by Equal Channel Angular Extrusion, J. Non-Cryst. Solids, 2003, 317, p 144–1451

I. Karaman, M. Haouaoui, and H.J. Maier, Nanoparticle Consolidation Using Equal Channel Angular Extrusion at Room Temperature, J. Mater. Sci., 2007, 42, p 1561–1576

M.A. Gibbs, K.T. Hartwig, L.R. Cornwell, R.E. Goforth, and E.A. Payzant, Texture Formation in Bulk Iron Processed by Simple Shear, Scripta Mater., 1998, 39, p 1699–1704

M. Haouaoui, K.T. Hartwig, and E.A. Payzant, Effect of Strain Path on Texture and Annealing Microstructure Development in Bulk Pure Copper Processed by Simple Shear, Acta Mater., 2005, 53, p 801–810

A.V. Nagasekhar, Y. Tick-Hon, and K.S. Ramakanth, Mechanics of Single Pass Equal Channel Angular Extrusion of Powder in Tubes, Appl. Phys. A, 2006, 85, p 185–194

W. Xu, X. Wu, T. Honma, S.P. Ringer, and K. Xia, Nanostructured Al-Al2O3 Composite Formed In Situ During Consolidation of Ultrafine Al Particles by Back Pressure Equal Channel Angular Pressing, Acta Mater., 2009, 57, p 4321–4330

R. Lapovok, D. Tomus, and B.C. Muddle, Low-Temperature Compaction of Ti–6Al–4V Powder Using Equal Channel Angular Extrusion with Back Pressure, Mater. Sci. Eng. A, 2008, 490, p 171–180

R. Lapovok, D. Tomus, and C. Bettles, Shear Deformation with Imposed Hydrostatic Pressure for Enhanced Compaction of Powder, Scripta Mater., 2008, 58, p 898–901

M. Balog, F. Simancik, O. Bajana, and G. Requena, ECA vs. Direct Extrusion—Techniques for Consolidation of Ultra-Fine Al Particles, Mater. Sci. Eng. A, 2009, 504, p 1–7

P. Quang, Y.G. Jeong, S.H. Hong, and H.S. Kim, Equal Channel Angular Pressing of Carbon Nanotube Reinforced Metal Matrix Nanocomposites, Key Eng. Mater., 2006, 328, p 325–328

R. Derakhshandeh and H.S.A. Jenabali Jahromi, An Investigation on the Capability of Equal Channel Angular Pressing for Consolidation of Aluminum and Aluminum Composite Powder, Mater.Des., 2011, 32, p 3377–3388

Y.T. Zhu and T.C. Lowe, Observations and Issues on Mechanisms of Grain Refinement During ECAP Process, Mater. Sci. Eng. A., 2000, 291, p 46–53

R. Lapovok, Damage Evolution Under Severe Plastic Deformation, Int. J. Fract., 2002, 115, p 159–172

Z. Zhang and D.L. Chen, Contribution of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites, Mater. Sci. Eng. A, 2008, 483–484, p 148–152

R. Jiang-wei and S. Ai-dang, Strengthening and Stress Drop of Ultrafine Grain Aluminum After Annealing, Trans. Nonferrous Met. Soc. China, 2010, 20, p 2139–2142

J.C. Werenskiold, Equal channel angular pressing (ECAP) of AA6082: Mechanical Properties, Texture and Microstructural Development, Ph.D. Thesis, The Norwegian University of Science and Technology, 2004

B. Clausen, E. Ustundag, and M.A.M. Bourke, Investigation of the Reduction of NiAl2O4. JCPDS-International Center for Diffraction Data, Adv. X-Ray Anal., 2001, 44, p 32–37

B. Wielage, T. Muller, and Th. Lampke, Numerical Simulation of Thermo-Elastic Behavior of Textile Structured Ceramic Matrix Composite Bearings, Int. J. Microstruct. Mater. Prop., 2008, 3, p 65–76

V.V. Ganesh and N. Chawla, Effect of Particle Orientation Anisotropy on the Tensile Behavior of Metal Matrix Composites: Experiments and Microstructure-Based Simulation, Mater. Sci. Eng. A, 2005, 391, p 342–353

N.B. Dhokey and R.K. Paretkar, Study of Wear Mechanisms in Copper-Based SiCp (20% by volume) Reinforced Composite, Wear, 2008, 265, p 117–133

D.A. Rigney, The Roles of Hardness in the Sliding Behavior of Materials, Wear, 1994, 175, p 63–69

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haghighi, R.D., Jahromi, S.A.J., Moresedgh, A. et al. A Comparison Between ECAP and Conventional Extrusion for Consolidation of Aluminum Metal Matrix Composite. J. of Materi Eng and Perform 21, 1885–1892 (2012). https://doi.org/10.1007/s11665-011-0108-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-0108-9