Abstract

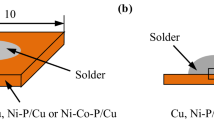

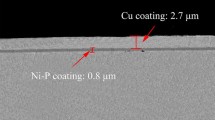

In this study, the microstructural evolution of Sn-3Ag-0.5Cu/Au/Pd(P)/Ni(P) microbumps during isothermal aging was examined by electron probe microanalysis and scanning electron microscopy equipped with electron backscatter diffraction. The Au/Pd(P)/Ni(P) trilayer was deposited on 85-μm (opening diameter) Cu pads with a thickness combination of 0.15 μm/0.2 μm/8 μm. The reaction of the Au/Pd(P) dual layer with the molten solder yielded plenty of AuSn4 and PdSn4 grains in the solder matrix after reflow, which has never been observed previously in the literature. At the interface, discontinuous, facet-type Cu6Sn5 [or (Cu,Ni)6Sn5] nucleated. Interestingly, the Cu6Sn5 transformed into layered Ni3Sn4 after subsequent aging for 250 h at 180°C. Moreover, the AuSn4 and PdSn4 agglomerated with each other and resettled to the region neighboring the interface. This configuration changed significantly when a pronounced corrosion occurred in the as-plated Ni(P) metallization pad. In the corroded Ni(P) case, Cu6Sn5 rarely appeared at the interface immediately after reflow, but a large quantity of PdSn4 formed in the solder region near the corroded Ni(P) layer. AuSn4 in this case distributed uniformly throughout the entire solder joint. Isothermal aging treatment drove the PdSn4 and AuSn4 to deposit onto the corroded Ni(P) surface, where they merged with each other as a dense layer of (Au0.61Pd0.30Ni0.09)Sn4 (250 h). The formation of the (Au,Pd,Ni)Sn4 layer over the corroded Ni(P) substrate provided a crack initiation site, deteriorating the mechanical reliability of the solder joint. The results of this study show that appropriate deposition of Au/Pd(P)/Ni(P) is very important for the thermal/mechanical reliability of microbumps.

Similar content being viewed by others

References

K.N. Tu and K. Zeng, Mater. Sci. Eng. R34, 1 (2001).

K. Zeng and K.N. Tu, Mater. Sci. Eng. R38, 55 (2002).

T. Laurila, V. Vuorinen, and J.K. Kivilahti, Mater. Sci. Eng. R49, 1 (2005).

C.E. Ho, S.C. Yang, and C.R. Kao, J. Mater. Sci.: Mater. Electron. 18, 155 (2007).

H. Roberts, S. Lamprecht, G. Ramos, and C. Sebald, Proceeding of SMTA Pan Pacific Microelectronics Symposium (2008), p. 1

K. Zeng, R. Stierman, D. Abbott, and M. Murtuza, JOM 58, 75 (2006).

K. Suganuma and K.S. Kim, JOM 60, 61 (2008).

H. Roberts and K. Johal, Lead-Free Soldering (New York: Springer, 2007), pp. 221–269.

Y.W. Yen, P.H. Tsai, Y.K. Fang, S.C. Lo, Y.P. Hsieh, and C. Lee, J. Alloys Compd. 503, 25 (2010).

J.W. Yoon, B.I. Noh, J.H. Yoon, H.B. Kang, and S.B. Jung, J. Alloys Compd. 509, 153 (2011).

C.E. Ho, R. Zheng, G.L. Luo, A.H. Lin, and C.R. Kao, J. Electron. Mater. 29, 1175 (2000).

S.P. Peng, W.H. Wu, C.E. Ho, and Y.M. Huang, J. Alloys Compd. 493, 431 (2010).

C.E. Ho (Ph.D. thesis, National Central University, Taiwan, June, 2002).

W.J. Boettinger, M.D. Vaudin, M.E. Williams, L.A. Bendersky, and W.R. Wagner, J. Electron. Mater. 32, 511 (2003).

T.B. Massalski, J.L. Murray, and L.H. Bennett, Binary Alloy Phase Diagrams (Metals Park, OH: American Society for Metals, 1986).

J.D. Bernal, Nature 122, 54 (1928).

K. Nogita and T. Nishimura, Scripta Mater. 59, 191 (2008).

S. Furuseth and H. Fjellvag, Acta Chem. Scand. A39, 537 (1985).

W.H. Wu, C.S. Lin, S.H. Huang, and C.E. Ho, J. Electron. Mater. 39, 2387 (2010).

C.E. Ho, W.H. Wu, L.H. Hsu, and C.S. Lin, J. Electron. Mater. 41, 11 (2012).

C.P. Lin and C.M. Chen, Microelectron. Reliab. 52, 385 (2012).

K.H. Kim, J. Yu, and J.H. Kim, Scripta Mater. 63, 508 (2010).

N. Biunno, Proceeding of Surface Mount Technology International (Edina, MN: SMTA, 1999), pp. 561–568.

B.K. Kim, S.J. Lee, J.Y. Kim, K.Y. Ji, Y.J. Yoon, M.Y. Kim, S.H. Park, and J.S. Yoo, J. Electron. Mater. 37, 527 (2008).

C.E. Ho, Y.M. Chen, and C.R. Kao, J. Electron. Mater. 28, 1231 (1999).

R. Kubiak, J. Less-Common Met. 80, 53 (1981).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ho, C., Wu, W., Wang, C. et al. Gold- and Palladium-Induced Embrittlement Phenomenon in Microbumps with Au/Pd(P)/Ni(P) Metallization Pads. J. Electron. Mater. 41, 3266–3275 (2012). https://doi.org/10.1007/s11664-012-2196-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-012-2196-1