Abstract

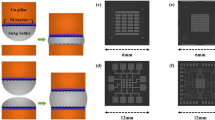

The Sn-3.5Ag-0.5Cu (wt.%) is the most promising replacement for the eutectic tin-lead solder alloy. Here, an investigation has been carried out to compare the interfacial reactions of the Cu pad of a ball grid array (BGA) substrate with molten eutectic Sn-3.5% Ag-0.5% Cu solder having different volumes. Two different sizes of BGA solder balls were used: 760-µm and 500-µm diameter. Scanning electron microscopy (SEM) was used to measure the consumed thickness of the Cu and also the thickness of the intermetallic compound (IMC). The soldering reaction was carried out at 230°C, 240°C, and 250°C for 1 min, 5 min, 10 min, and 20 min. The Cu consumption was much higher for the Sn-Ag-Cu solder with higher volume. On the other hand, the mean thickness of the intermetallics for solder with smaller volume was thicker than that of the bigger solder balls. The Cu3Sn compound was also observed at the interface between the Cu6Sn5 IMCs and Cu substrate for longer reflow for the both solder balls. Larger Cu6Sn5 IMCs were observed in the bulk of the solder with bigger volume. A simplistic theoretical approach is carried out to find out the amount of Cu6Sn5 IMCs in the bulk of the solder by measurement of the Cu consumption from the substrate and the thickness of the IMCs that form on the interface.

Similar content being viewed by others

References

R.J. Klein Wassink, Soldering in Electronics, 2nd ed. (Ayr, Scotland: Electrochemical Publications Ltd., 1997), p. 141.

J.H. Lau, Solder Joint Reliability—Theory and Application (New York: Van Nostrand Reinhold, 1991), pp. 236–243.

Y.C. Chan, A.C.K. So, and J.K.L. Lai, Mater. Sci. Eng. B 55, 5 (1998).

A.C.K. So, Y.C. Chan, and J.K.L. Lai, IEEE Trans. CMPT, Part B 20, 463 (1997).

D.R. Fear, H.S. Morgan, S.N. Burcheit, and J.H. Lau, The Mechanics of Solder Alloy Interconnects (New York: Van Nostrand Reinhold, 1994).

M. Schaefer, W. Laub, R.A. Fournelle, and J. Liang, Design and Reliability of Solders and Solder Interconnects, eds. R.K. Mahidhara et al. (Warrendale, PA: TMS, 1997), pp. 247–258.

H.K. Kim and K.N. Tu, Appl. Phys. Lett. 67, 2002 (1995).

L.H. Su, Y.W. Yen, C.C. Lin, and S.W. Chen, Metall. Mater. Trans. B 28B, 927 (1997).

C.H. Ma and R.A. Swalin, Acta Metall. 8, 388 (1960).

S. Chada, R.A. Fournelle, W. Laub, and D. Shangguan, J. Electron. Mater. 29, 1214 (2000).

B. Salam, N.N. Ekere, and D. Rajkumar, Electronic Components and Technology Conf. (Piscataway, NJ: IEEE, 2001), pp. 471–477.

H.K. Kim and K.N. Tu, Phys. Rev. B 53, 16027 (1996).

A.J. Sunwoo, J.W. Morris, Jr., and G.K. Lucey, Jr., Metall. Trans. A 23A, 1323 (1992).

H.L. Morris and J.W. Reynolds, J. Electron. Mater. 24, 1429 (1995).

A. Sharif, Y.C. Chan, and R.A. Islam, Mater. Sci. Eng. B 106, 120 (2004).

H.K. Kim, H.K. Liou, and K.N. Tu, Appl. Phys. Lett. 66, 2337 (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Islam, M.N., Sharif, A. & Chan, Y.C. Effect of volume in interfacial reaction between eutectic Sn-3.5% Ag-0.5% Cu solder and Cu metallization in microelectronic packaging. J. Electron. Mater. 34, 143–149 (2005). https://doi.org/10.1007/s11664-005-0225-z

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-005-0225-z