Abstract

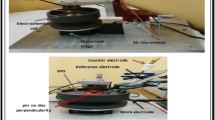

Surface damage at interfaces of modular implants results from repeated fretting contacts between metallic surfaces in a corrosive environment. As a first step in understanding this complex process, multi-asperity contact experiments were conducted to characterize roughness evolution due to action of contact loads and exposure to a reactive environment. Cobalt–chromium specimens with surface roughness similar to modular implant were first subjected to only contact loading and subsequently, to alternating contact loads and exposure to reactive environment. During repeated normal contact loading, amplitude of surface roughness reached a steady value after decreasing during the first few cycles. However during the second phase surface roughness amplitude continuously evolved—decreasing during contact loading and increasing on exposure to corrosive environment. The increase in roughness amplitude during surface reaction depended on the magnitude of applied contact loads. A damage mechanism that incorporates contact-induced residual stress development and stress-assisted dissolution is proposed to elucidate the measured surface roughness evolution.

Similar content being viewed by others

References

Hallab NJ, Jacobs JJ (2003) Orthopedic implant fretting corrosion. Corros Rev 21(2–3):183–213.

Brown SA, Flemming CAC, Kawalec JS, Placko HE, Vassaux C, Merritt K, Payer JH, Kraay MJ (1995) Fretting corrosion accelerates crevice corrosion of modular hip tapers. J Appl Biomater 6:19–26.

Hallab NJ, Messina C, Skipor A, Jacobs JJ (2004) Differences in the fretting corrosion of metal–metal and ceramic–metal modular junctions of total hip replacements. J Orthop Res 22:250–259.

He D, Zhang T, Wu Y (2001) Mechanisms responsible for synergy between fretting and corrosion for three biomaterials in saline solution. Wear 250:180–187.

Goldberg JR, Gilbert JL, Jacobs JJ, Bauer TW, Paprosky W, Leurgans S (2002) A multicenter retrieval study of the taper interfaces of modular hip prostheses. Clin Orthop Relat Res (401):149–161.

Kraft CN, Burian B, Diedrich O, Wimmer MA (2001) Implications of orthopedic fretting corrosion particles on skeletal muscle microcirculation. J Mater Sci Mater Med 12:1057–1062.

Goldberg JR, Gilbert JL (2003) In vitro corrosion testing of modular hip tapers. J Biomed Mater Res Part B, Appl Biomater 64B:78–93.

Wimmer MA, Loos J, Nassutt R, Heitkemper M, Fischer A (2001) The acting wear mechanisms on metal-on-metal hip joint bearings: in vitro results. Wear 250:129–139.

Gilbert JL, Buckley CA, Jacobs JJ (1993) In vivo corrosion of modular hip prosthesis components in mixed and similar metal combinations. The effect of crevice, stress, motion, and alloy coupling. J Biomed Materi Res 27:1533–1544.

Brown SA, Merritt K (1981) Fretting corrosion in saline and serum. J Biomed Materi Res 15(4):479–488.

Bundy KJ (1994) Corrosion and other electrochemical aspects of biomaterials. Crit Rev Biomed Eng 22(3–4):139–251.

Bundy KJ et al (1985) Ph shifts and precipitation associated with metal–ions in tissue culture. Biomaterials 6(2):89–96.

Bundy KJ, Williams CJ, Luedemann RE (1991) Stress-enhanced ion release—the effect of static loading. Biomaterials 12(7):627–639.

Gil FJ et al (2003) Fretting corrosion behaviour of ball-and-socket joint on dental implants with different prosthodontic alloys. Bio Med Mater Eng 13:27–34.

Viceconti M et al (1997) Fretting wear in a modular neck hip prosthesis. J Biomed Materi Res 35(2):207–216.

Viceconti M et al (1996) Design-related fretting wear in modular neck hip prosthesis. J Biomed Materi Res 30(2):181–186.

Gilbert JL, Jacobs JJ (1997) The mechanical and electrochemical processes associated with taper fretting crevice corrosion: a review. In: Marlowe DE, Parr JE, Mayor MB (eds) Modularity of orthopedic implants. American Society Testing and Materials, W Conshohocken, pp 45–59.

Jacobs JJ, Gilbert JL, Urban RM (1998) Corrosion of metal orthopaedic implants. J Bone Jt Surg-Am Vol 80A(2):268–282.

Gilbert JL, Jacobs JJ (1997) The mechanical and electrochemical processes associated with taper fretting crevice corrosion: a review. Modularity of Orthopedic Implants 8:45–59.

Archard JF (1957) Elastic deformation and the laws of friction. Proc R Soc Lond 243(1233):190–205.

Greenwood JA, Williamson JBP (1966) Contact of nominally flat surfaces. Proc R Soc Lond 295(1442):300–319.

Whitehouse DJ, Archard JF (1970) The properties of random surfaces of significance in their contact. Proc R Soc Lond 316(1524):97–121.

Onions RA, Archard JF (1973) The contact of surfaces having a random structure. J Phys D: Appl Phys 6:289–304.

Bush AW, Gibson RD, Thomas TR (1975) The elastic contact of a rough surface. Wear 35:87–111.

Johnson KL, Greenwood JA, Higgins JG (1985) The contact of elastic regular wavy surfaces. Int J Mech Sci 27(6):383–396.

Chang WR, Etsion I, Bogy DB (1987) An elastic-plastic model for the contact of rough surfaces. J Tribol 109:257–263.

Yan W, Komvopoulos K (1998) Contact analysis of elastic-plastic fractal surfaces. J Appl Physi 84(7):3617–3624.

Ciavarella M, Demelio G, Barber JR, Jang YH (2000) Linear elastic contact of the Weierstrass profile. Proc R Soc Lond 456:387–405.

Gong ZQ, Komvopoulos K (2003) Effect of surface patterning on contact deformation of elastic-plastic layered media. J Tribol 125:16–24.

Abbott EJ, Firestone FA (1933) Specifying surface quality—a method based on accurate measurement and comparison. Mech Eng 55:569.

Kogut L, Etsion I (2002) Elastic-plastic contact analysis of a sphere and a rigid flat. J Appl Mech 69:657–662.

Jackson RL, Green I (2003) A finite element study of elasto-plastic hemispherical contact. In: STLE/ASME Joint International Tribology Conference. ASME, Ponte Vedra Beach, Florida USA.

Zhao Y, Maietta DM, Chang L (2000) An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow. J Tribol 122:86–93.

Gao YF, Bower AF, Kim KS, Lev L, Cheng YT (2006) The behavior of an elastic-perfectly plastic sinusoidal surface under contact loading. Wear 261(2):145–154.

Gao YF, Bower AF (2006) Elastic-plastic contact of a rough surface with Weierstrass profile. Proceedings of the Royal Society a—Mathematical Physical and Engineering Sciences 462(2065):319–348.

Fraker AC (ed) ASM handbook. Corrosion of metallic implants and prosthetic devices, vol 13, pp 1324–1335.

Herrera M, Espinoza A, Mendez J, Castro M, Lopez J, Rendon J (2005) Effect of C content on the mechanical properties of solution treated as-cast ASTM F-75 alloys. J Mat Sci Mat Med 16(7):607–611.

Kilner T, Laanemae WM, Pilliar R, Weatherly GC, Macewen SR (1986) Static mechanical-properties of cast and sinter-annealed cobalt–chromium surgical implants. J Mater Sci 21(4):1349–1356.

Barber JR, Ciavarella M (2000) Contact mechanics. Int J Solids Struct 37:29–43.

Kim KS, Hurtado JA, Tan H (1999) Evolution of a surface-roughness spectrum caused by stress in nanometer-scale chemical etching. Phys Rev Lett 83(19):3872–3875.

Acknowledgments

The authors gratefully acknowledge the financial support for this research provided by Iowa State University under the Special Research Initiation Grant (SPRIG) award.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ryu, JJ., Dayal, V. & Shrotriya, P. Onset of Surface Damage in Modular Orthopedic Implants: Influence of Normal Contact Loading and Stress-assisted Dissolution. Exp Mech 47, 395–403 (2007). https://doi.org/10.1007/s11340-006-9028-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-006-9028-2