Abstract

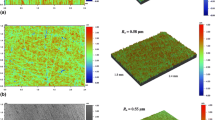

The employment of surface texturing for improved tribological contacts has spread over the years. The possibilities of designing and manufacturing textured surfaces with predetermined geometries have multiplied as well as the need of performing experimental laboratory tests before applying the surfaces in an industrial context. In this paper, a number of experimental tests were performed using a novel test rig, called axial sliding test, simulating the contact of surfaces under pure sliding conditions. The aim of the experiments is to evaluate the frictional behavior of a new typology of textured surfaces, the so-called multifunctional surfaces, characterized by a plateau area able to bear loads and a deterministic pattern of lubricant pockets. Six surface typologies, namely three multifunctional and three machined using classical processes, were chosen to slide against a mirror-polished counterpart. A number of experiments were carried out at different normal pressures employing for all specimens the same reciprocating movement and the same lubrication. The measured friction forces were plotted against the incremental normal pressure, and the friction coefficients were calculated. The results comparison showed clearly how employing multifunctional surfaces can reduce friction forces up to 50 % at high normal loads compared to regularly ground or turned surfaces. Friction coefficients approximately equal to 0.12 were found for classically machined surfaces, whereas the values were 0.06 for multifunctional ones. All the specimens were characterized before and after testing. Wear occurrence was not detected on the tested surfaces except for the mirror-polished one which underwent all the experiments.

Similar content being viewed by others

References

Bruzzone, A.A.G., Costa, H.L., Lonardo, P.M., Lucca, D.A.: Advances in engineered surfaces for functional performance. CIRP Ann. Manuf. Technol. 57, 750–769 (2008)

De Chiffre, L., Kunzmann, H., Peggs, G.N., Lucca, D.A.: Surfaces in precision engineering, microengineering and nanotechnology. CIRP Ann. Manuf. Technol. 52(2), 561–577 (2007)

Evans, C.J., Bryan, J.B.: “Structured”, “textured” or “engineered” surfaces. CIRP Ann. Manuf. Technol. 48(2), 541–556 (1999)

Stachowiak, G., Podsialdo, P.: 3-D characterization, optimization and classification of textured surfaces. Tribol. Lett. 32, 13–21 (2008)

Santochi, M., Vignale, M.: A study on the functional properties of a honed surface. CIRP Ann. Manuf. Technol. 31(1), 431–434 (1982)

Stout, K.J., Spedding, T.A.: The characterization of internal combustion engine bores. Wear 83, 311–326 (1982)

Whitehouse, D.J.: Some theoretical aspects of a practical measurement problem in plateau honing. Int. J. Prod. Res. 21(2), 215–221 (1983)

Stout, K.J., Sullivan, P.J., Dong, W.P., Mainsah, E., Luo, N., Mathia, T., Zahouani, H.: The development of methods for the characterization of roughness in three dimensions. Commission of the European Communities, UK (1993)

Holmberg, K.: The mechanism of lubrication in low speed rolling contacts. J. Tribol. 111, 703–707 (1989)

Sørensen, C.G., Bech, J.I., Andreasen, J.L., Bay, N., Engel, U., Neudecker, T.: A basic study of the influence of surface topography on mechanisms of liquid lubrication in metal forming. CIRP Ann. Manuf. Technol. 48(1), 203–208 (1999)

Koszela, W., Pawlus, P., Galda, L.: The effect of oil pockets size and distribution on wear in lubricated sliding. Wear 263, 1585–1592 (2007)

Reng, N., Nanbu, T., Yasuda, Y., Zhu, D., Wang, Q.: Micro textures in concentrated-conformal-contact lubrication: effect of distribution patterns. Tribol. Lett. 28, 275–285 (2007)

Pettersson, U., Jacobson, S.: Textured surfaces for improved lubrication at high pressure and low sliding speed of roller/piston in hydraulic motors. Tribol. Int. 40, 355–359 (2007)

Costa, H.L., Hutchings, I.M.: Effects of die surface patterning on lubrication in strip drawing. J. Mater. Process. Technol. 209, 1175–1180 (2009)

Vrbka, M., Šamánek, O., Šperka, P., Návrat, T., Křupka, I., Hartl, M.: Effect of surface texturing on rolling contact fatigue within mixed lubricated non-conformal rolling/sliding contacts. Tribol. Int. 43, 1457–1465 (2010)

Kaminski, J., Facht, J., Sjoblom, U.: Manufacturing of Dimpled Surfaces in hard turning and subsequent honing operation. In: Proceedings 12th Euspen International Conference. Stockholm, Sweden, pp. 49–52 (2012)

Ramesh, A., Akram, W., Mishra, P.S., Cannon, A.H., Polycarpou, A.A., King, W.P.: Friction characteristics of microtextured surfaces under mixed and hydrodynamic lubrication. Tribol. Int. 57, 170–176 (2013)

Friis, K.S., Godi, A., De Chiffre, L.: Characterization and robust filtering of multifunctional surfaces using ISO standards. Meas. Sci. Technol. 22, art.125101 (2011)

Eriksen, R.S., Arentoft, M., Grønbæk, J., Bay, N.: Manufacture of functional surfaces through combined application of tool manufacturing process and Robot Assisted Polishing. CIRP Ann. Manuf. Technol. 61(1), 563–566 (2012)

Godi, A., Grønbæk, J., Mohaghegh, K., Klit, P., De Chiffre, L.: An axial sliding test for machine elements surfaces. In Proceedings 15th NordTrib. Trondheim, Norway, ISBN 978-82-14-05270-1 (2012)

Grønbæk, J.: Stripwinding of Tool for Bulk Metal Forming. Ph.D. Thesis, Technical University of Denmark (1981) (In Danish)

Grønbæk, J.: Application of stripwinding tool to large reduction cold forging processes. In: Proceedings of the North American Manufacturing Research Conference (NAMRC-X). Hamilton, Canada, pp. 225–232 (1982)

Grønbæk, J.: Stripwound cold-forging tools—a technical and economical alternative. J. Mater. Process. Technol. 35, 483–493 (1992)

Sidenius, I.: Aksler. Kiler, fedre og splines. Krympning og roterende skiver. Kompendium til maskinelementer KP4, Polyteknisk Forlag, Denmark (1971) (In Danish)

Texaco Multifak® EP 0,1,2. http://www.rolandjrobertdistributor.com/files/Multifak_ep.pdf. Accessed 29 Nov 2012

Blunt, L., Jiang, X.: Advanced Techniques for Assessment Surface Topography. Kogan Page Science, UK (2003)

Brinkmann, S., Bodschwinna, H., Lemke, H.W.: Accessing roughness in three-dimensions using Gaussian regression filtering. Int. J. Mach. Tools Manuf. 41, 2153–2161 (2001)

Godi, A., Khüle, A., De Chiffre, L.: A plateau-valley separation method for multifunctional surfaces characterization. In: Proceedings 12th Euspen International Conference. Stockholm, Sweden, pp. 190–193 (2012)

Guo, K., Zhang, X., Li, H., Meng, G.: Non-reversible friction modeling and identification. Arch. Appl. Mech. 78, 795–809 (2008)

Wojewoda, J., Stefański, A., Wiercigroch, M., Kapitaniak, T.: Hysteretic effects of dry friction: modeling and experimental studies. Phil. Trans. R. Soc. A 366, 747–765 (2008)

JCGM 100: Evaluation of measurement data—guide to the expression of uncertainty in measurement (2008)

Gasparin, S.: Verification of Tolerance Chains in Micro Manufacturing. Ph.D. Thesis, Technical University of Denmark (2012)

Alicona Imaging GmbH: Alicona Infinite Focus®, IFM Manual (2009)

Acknowledgments

The authors would like to thank the Danish National Advanced Technology Foundation for funding this research under the project “Manufacture and characterization of industrial multifunctional surfaces.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Godi, A., Mohaghegh, K., Grønbæk, J. et al. Testing of Newly Developed Functional Surfaces Under Pure Sliding Conditions. Tribol Lett 51, 171–180 (2013). https://doi.org/10.1007/s11249-013-0162-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0162-6