Abstract

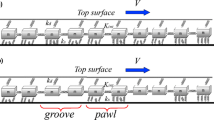

The ability to tune friction by tailoring surface topographies at micron length scales and by changing the relative orientation of crystallites at the atomic scale is well established. Here, we investigate if the two concepts combine, i.e. if the relative orientation of surfaces affects dry friction between laser-textured surfaces. Laser patterning was used on austenitic stainless steel substrates and on tribometer testing balls made of 100Cr6 to create linear periodic arrays with different structural wavelengths or periodicities (5, 9 and 18 μm). Pairing each substrate with a ball of the same periodicity, the different arrays were subjected to dry sliding tests at 0°/90° relative alignment between the linear patters. We observe that the patterning reduces friction after running-in. The reduction increases with decreasing wavelength and also depends sensitively on the relative alignment and the chemistry of the sliding surfaces. Our results highlight the possibility to create tailored contacting surface geometries leading to tunable frictional properties.

Similar content being viewed by others

References

Bowden, F.P., Tabor, D.: Mechanisms of metallic friction. Nature 150, 197–199 (1942)

Hirano, M., Shinjo, K., Kaneko, R., Murata, Y.: Anisotropy of frictional forces in muscovite mica. Phys. Rev. Lett. 67, 2642–2645 (1991)

Dienwiebel, M., et al.: Superlubricity of graphite. Phys. Rev. Lett. 62(126101), 1–4 (2004)

Sondhauß, J., Fuchs, H., Schirmeisen, A.: Frictional properties of a mesoscopic contact with engineered surface roughness. Tribol. Lett. 42, 319–324 (2011)

Urbakh, M., Klafter, J., Gourdon, D., Israelachvili, J.: The nonlinear nature of friction. Nature 430, 525–528 (2004)

Willis, E.: Surface finish in relation to cylinder liners. Wear 109, 351–366 (1986)

Gerbig, Y., Dumitru, G., Romano, V., Spassov, V., Haefke, H.: Effects of laser texturing on technical surfaces. MRS Proc. 750, Y5.37 (2002)

Etsion, I., Kligerman, Y., Halperin, G.: Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 42, 511–516 (1999)

Pettersson, U., Jacobson, S.: Influence of surface texture on boundary lubricated sliding contacts. Tribol. Int. 36, 857–864 (2003)

Rapoport, L., et al.: Wear life and adhesion of solid lubricant films on laser-textured steel surfaces. Wear 267, 1203–1207 (2009)

Li, J., et al.: Effect of surface laser texture on friction properties of nickel-based composite. Tribol. Int. 43, 1193–1199 (2010)

Kelly, M.K., et al.: High resolution thermal processing of semiconductors using pulsed-laser interference patterning. Phys. Stat. Sol. A 166, 651–657 (1998)

Mücklich, F., et al.: Laser interference metallurgy-using interference as a tool for micro/nano structuring. Int. J. Mater. Res. 97, 1337–1344 (2006)

Sun, Z., et al.: Two- and three-dimensional micro/nanostructure patterning of CdS—polymer nano composites with a laser interference technique and in situ synthesis. Nanotechnology 19(3), 1–8 (2008)

Huang, J., et al.: Tunable surface texturing by polarization-controlled three-beam interference. J. Micromech. Microeng. 20, 1–6 (2010)

Daniel, C., Mücklich, F.: Micro-structural characterization of laser interference irradiated Ni/Al multi-films. Appl. Surf. Sci. 242, 140–146 (2005)

Nebel, C.E., et al.: Laser-interference crystallization of amorphous silicon—applications and properties. Phys. Stat. Sol. A 166, 667–673 (1998)

Gachot, C., et al.: Comparative study of grain sizes and orientation in microstructured Au, Pt and W thin films designed by laser interference metallurgy. Appl. Surf. Sci. 255, 5626–5632 (2009)

Gao, F., Leach, R., Petzing, J., Coupland, J.: Surface measurement errors using commercial scanning white light interferometers. Meas. Sci. Technol. 19, 1–13 (2008)

Lasagni, A.F., D′Alessandria, M., Giovanelli, R., Mücklich, F.: Advanced design of periodical architectures in bulk metals by means of laser interference metallurgy. Appl. Surf. Sci. 254, 930–936 (2007)

Lasagni, A.F.: Advanced design of periodical structures by laser interference metallurgy in the micro/nano scale on macroscopic areas. PhD thesis, Saarland University, Saarbrücken (2006)

Carbone, G., Bottiglione, F.: Asperity contact theories—do they predict linearity between contact area and load. J. Mech. Phys. Solids 56, 2555–2572 (2008)

Talonen, J., Nenonen, P., Pape, G., Hänninen, H.: Effect of strain rate on the strain- induced γ → α′-martensite transformation and mechanical properties of austenitic stainless steels. Metall. Mater. Trans. A 36A, 421–432 (2005)

Haynes, W.M., Lyde, D.R.: Handbook of Chemistry and Physics. CRC Press, Taylor and Francis Group, Boca Raton (2010)

Renusch, D., Veal, B., Natesan, K., Grimsditch, M.: Transient oxidation in Fe–Cr–Ni alloys—a Raman-scattering study. Oxid. Met. 46, 365–381 (1996)

Oh, S.J., Cook, D.C., Townsend, H.E.: Characterization of iron oxides commonly formed as corrosion products on steel. Hyperfine Interact. 112, 59–66 (1998)

McCarty, K.F., Boehme, D.R.: A Raman study of the systems Fe3–xCrxO4 and Fe2–xCrxO3. J. Solid State Chem. 79, 19–27 (1989)

Farrow, R.L., Benner, R.E., Nagelberg, A.S., Mattern, P.L.: Characterization of surface oxides by Raman spectroscopy. Thin Solid Films 73, 353–358 (1980)

Raman, R.K.S., Gleeson, B., Young, D.J.: Laser Raman spectroscopy—a technique for rapid characterisation of oxide scale layers. Mater. Sci. Technol. 14, 373–376 (2011)

Odziemkowski, M.S., Schuhmacher, T.T., Gillham, R.W., Reardon, E.J.: Mechanism of oxide film formation on iron in simulating groundwater solutions: Raman spectroscopic studies. Corros. Sci. 40, 371–389 (1998)

De Faria, D.L.A., De Oliveira, M.T.: Raman microspectroscopy of some iron oxides and oxyhydroxides. J. Raman Spectrosc. 28, 873–878 (1997)

Müser, M.H.: Der mikroskopische Ursprung der Reibung. Phys. J. 2, 43–48 (2003)

Campbell, W.E. Proceedings of M.I.T., p. 197. MIT Press, Cambridge (1940)

He, G., Robbins, M.O., Müser, M.H.: Adsorbed layers and the origin of static friction. Science 284, 1650–1652 (1999)

Persson, B.N.J.: Theory of rubber friction and contact mechanics. J. Chem. Phys. 115, 3840–3861 (2001)

Hübner, W.: Phase transformations in austenitic stainless steels during low temperature tribological stressing. Tribol. Int. 34, 231–236 (2001)

Schramm, R.E., Reed, R.P.: Stacking fault energy of seven commercial austenitic stainless steels. Metall. Mater. Trans. A 6A, 1345–1351 (1975)

Feller, H.G., Gao, B.: Correlation of tribological and metal physics data: the role of stacking fault energy. Wear 132, 1–7 (1989)

Rigney, D.A.: Large strains associated with sliding contact of metals. Mater. Res. Innov. 1, 231–234 (1998)

Kuhlmann-Wilsdorf, D.: Dislocation behavior in fatigue IV. Quantitative interpretation of friction stress and back stress derived from hysteresis loops. Mater. Sci. Eng. 39, 231–245 (1979)

Prodanov, N., Gachot, C., Rosenkranz, A., Mücklich, F., Müser, M.H.: Contact mechanics of laser-textured surfaces—correlating contact area and friction. Tribol Lett. doi:10.1007/s11249-012-0064-z

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gachot, C., Rosenkranz, A., Reinert, L. et al. Dry Friction Between Laser-Patterned Surfaces: Role of Alignment, Structural Wavelength and Surface Chemistry. Tribol Lett 49, 193–202 (2013). https://doi.org/10.1007/s11249-012-0057-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-0057-y