Abstract

Purpose

The purpose was to calculate distributions of powder strength of a cohesive bed to explain the de-agglomeration of lactose.

Methods

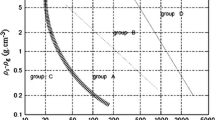

De-agglomeration profiles of Lactohale 300® (L300) and micronized lactose (ML) were constructed by particle sizing aerosolised plumes dispersed at air flow rates of 30–180 l/min. The work of cohesion distribution was determined by inverse gas chromatography. The primary particle size and tapped density distributions were determined. Powder strength distributions were calculated by Monte Carlo simulations from distributions of particle size, work of cohesion and tapped density measurements.

Results

The powder strength distribution of L300 was broader than that of ML. Up to 85th percentile, powder strength of L300 was lower than ML which was consistent with the better de-agglomeration of L300 at low flow rates. However, ~15% of L300 particles had higher powder strength than ML which likely to cause lower de-agglomeration for L300 at high air flow rates.

Conclusion

Cohesive lactose powders formed matrices of non-homogenous powder strength. De-agglomeration of cohesive powders has been shown to be related to powder strength. This study provided new insights into powder de-agglomeration by a new approach for calculating powder strength distributions to better understand complex de-agglomeration behaviour.

Similar content being viewed by others

References

Jones MD, Price R. The influence of fine excipient particles on the performance of carrier-based dry powder inhalation formulations. Pharm Res. 2006;23:1665–74.

Louey M, Stewart P. Particle interactions involved in aerosol dispersion of ternary interactive mixtures. Pharm Res. 2002;19:1524–31.

Xu Z, Mansour H, Hickey A. Particle interactions in dry powder inhaler unit processes: a review. J Adh Sci Technol. 2011;25:451–82.

Qui Y, Adjei AL, Gupta PK. Absorption and bioavailability of inhaled peptides and proteins. In: Adjei AL, Gupta PK, editors. Inhalation delivery of therapeutic peptides and proteins. New York: Marcel Dekker, Inc.; 1997.

Adi H, Larson I, Chiou H, Young P, Traini D, Stewart P. Agglomerate strength and dispersion of salmeterol xinafoate from powder mixtures for inhalation. Pharm Res. 2006;23:2556–65.

Cheng D. The tensile strength of powders. Chem Eng Sci. 1968;23:1405–20.

Schubert H. Tensile strength of agglomerates. Powder Technol. 1975;11:107–19.

Ashton M, Cheng D, Farley R, Valentin F. Some investigations into the strength and flow properties of powders. Rheologica Acta. 1965;4:206–18.

Kocovaand S, Pilpel N. The tensile strength of mixtures of cohesive powders. Powder Technol. 1973;7:51–67.

Shinoharaand K, Tanaka T. 3rd International Congress. Marianske Lazne: CHISA; 1969.

Rumpf H. The strength of granules and agglomerates. In: Knepper WA, editor. International symposium on agglomeration 1st. New York: Interscience; 1962. p. 379–418.

Kendall K, Stainton C. Adhesion and aggregation of fine particles. Powder Technol. 2001;121:223–9.

Das S, Larson I, Young P, Stewart P. Influence of storage relative humidity on the dispersion of salmeterol xinafoate powders for inhalation. J Pharm Sci. 2009;98:1015–27.

Adi S, Adi H, Chan H, Finlay W, Tong Z, Yang R, Yu A. Agglomerate strength and dispersion of pharmaceutical powders. J Aerosol Sci. 2011;42:285–94.

Behara SRB, Kippax P, McIntosh MP, Morton DAV, Larson I, Stewart P. Structural influence of cohesive mixtures of salbutamol sulphate and lactose on aerosolisation and de-agglomeration behaviour under dynamic conditions. Eur J Pharm Sci. 2011;42:210–9.

Behara SRB, Larson I, Kippax P, Morton DAV, Stewart P. An approach to characterising the cohesive behaviour of powders using a flow titration aerosolisation based methodology. Chem Eng Sci. 2011;66:1640–8.

Das SC, Larson I, Morton DAV, Stewart PJ. Determination of the Polar and Total Surface Energy Distributions of Particulates by Inverse Gas Chromatography. Langmuir. 2011;27:521–3.

Vanoss CJ, Good RJ, Chaudhury MK. Additive and nonadditive surface-tension components and the interpretation of contact angles. Langmuir. 1988;4:884–91.

Alway B, Sangchantra R, Stewart PJ. Modelling the dissolution of diazepam in lactose interactive mixtures. Int J Pharm. 1996;130:213–24.

Behara SRB, Larson I, Kippax P, Morton DAV, Stewart P. Insight into pressure drop efficiencies of dry powder inhalers. Eur J Pharm Sci. 2012;46:142–8.

Coady TJ, Davies HJ, Barnes P. Evaluation of a breath actuated pressurized aerosol. Clin Allergy. 1976;6:1–6.

Sarinas PSA, Robinson TE, Clark AR, Canfield J, Chitkara RK, Fick RB. Inspiratory flow rate and dynamic lung function in cystic fibrosis and chronic obstructive lung diseases. Chest. 1998;114:988–92.

Wijkstra PJ, Vandermark TW, Boezen M, Vanaltena R, Postma DS, Koeter GH. Peak inspiratory mouth pressure in healthy-subjects and in patients with COPD. Chest. 1995;107:652–6.

Thielmann F, Naderi M, Burnett D, Jervis H. Investigation of the acid-base properties of an MCM-supported ruthenium oxide catalyst by inverse gas chromatography and dynamic vapour sorption. Jackson, SD, Hargreaves, JSJ, Lennon, D, (Eds.), Catalysis in application: Great Britain, Royal Soc. Chem. 2003;237.

Traini D, Young PM, Thielmann F, Acharya M. The influence of lactose pseudopolymorphic form on salbutamol sulfate-lactose interactions in DPI formulations. Drug Dev Ind Pharm. 2008;34:992–1001.

Grimsey IM, Feeley JC, York P. Analysis of the surface energy of pharmaceutical powders by inverse gas chromatography. J Pharm Sci. 2002;91:571–83.

Tay T, Das S, Stewart P. Magnesium stearate increases salbutamol sulphate dispersion: what is the mechanism? Int J Pharm. 2010;383:62–9.

Thielmann F, Burnett DJ, Heng JYY. Determination of the surface energy distributions of different processed lactose. Drug Dev Ind Pharm. 2007;33:1240–53.

Yla-Maihaniemi PP, Heng JYY, Thielmann F, Williams DR. Inverse gas chromatographic method for measuring the dispersive surface energy distribution for particulates. Langmuir. 2008;24:9551–7.

Schultz J, Lavielle L, Martin C. The role of the interface in carbon-fiber epoxy composites. J Adh. 1987;23:45–60.

Carr RL. Evaluating flow properties of solids. Chem Eng. 1965;72:163–8.

Marquardt D. An algorithm for least-squares estimation of nonlinear parameters. J So Ind Appl Math. 1963;11:431–41.

Draper N, Smith H. Applied regression analysis. New York: Willey; 1981.

Das S, Zhou Q, Morton D, Larson I, Stewart P. Use of surface energy distributions by inverse gas chromatography to understand mechanofusion processing and functionality of lactose coated with magnesium stearate. Eur J Pharm Sci. 2011;43:325–33.

Ho R, Hinder SJ, Watts JF, Dilworth SE, Williams DR, Heng JYY. Determination of surface heterogeneity of D-mannitol by sessile drop contact angle and finite concentration inverse gas chromatography. Int J Pharm. 2010;387:79–86.

Acknowledgments AND DISCLOSURES

Srinivas Ravindra Babu Behara (SRBB) is a recipient of Monash International Postgraduate Research Scholarship and Monash Research Graduate Scholarship. The authors would like to thank BorculoIngredientsDomo for providing lactohale 300 powder.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, S.C., Behara, S.R.B., Bulitta, J.B. et al. Powder Strength Distributions for Understanding De-agglomeration of Lactose Powders. Pharm Res 29, 2926–2935 (2012). https://doi.org/10.1007/s11095-012-0799-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-012-0799-0