Abstract

ABS is an engineering plastic that has butadiene part uniformly distributed over the acrylonitrile-styrene matrix. It possesses excellent toughness, good dimensional stability, easy processing ability, chemical resistance, and cheapness. However, it suffers from inherent shortcomings in terms of mechanical strength and vulnerability to environmental conditions. Furthermore, it is non-conducting and easily fretted. Plating on ABS can serve to enhance the strength and structural integrity as well as to improve durability and thermal resistance resulting in metallic properties on the ABS material. ABS is described as the most suitable candidate for plating because it is possible to deposit an adherent metal coating on it by only the use of chemical pretreatment process and without the use of any mechanical abrasion. This article aims to review the history of ABS plastics, properties of ABS, processes and mechanisms of plating, and studies of plating on ABS involving mainly eco-friendly methods of plating by discussing the literature published in recent years. The details of electroplating of ABS carried out in the authors’ laboratory are also presented.

Similar content being viewed by others

References

Wang W, Ji S, Lee I (2013) A facile method of nickel electroless deposition on various neutral hydrophobic polymer surfaces. Appl Surf Sci 283:309–320. doi:10.1016/j.apsusc.2013.06.108

Tran V, Massardier V, Guyot A, Nguyen T (1993) Interactions in metal-polymer-metal interfaces. Polymer 34(15):3179–3183

Grundmeier G, Stratmann M (2005) Adhesion and de-adhesion mechanisms at polymer/metal interfaces: mechanistic understanding based on in situ studies of buried interfaces. Annu Rev Mater Res 35:571–615

Holubar P, Jilek M, Sima M (2000) Present and possible future applications of superhard nanocomposite coatings. Surf Coat Technol 133:145–151

Long DP, Blackburn JM, Watkins JJ (2000) Chemical fluid deposition: a hybrid technique for low-temperature metallization. Adv Mater 12(12):913–915

Cheng K, Yang MH, Chiu WW, Huang CY, Chang J, Ying TF, Yang Y (2005) Ink-jet printing, self-assembled polyelectrolytes, and electroless plating: low cost fabrication of circuits on a flexible substrate at room temperature. Macromol Rapid Comm 26(4):247–264

Garcia A (2011) Ligand induced electroless plating of polymers. PhD Dissertation, École Polytech

Arai S, Sato T, Endo M (2011) Fabrication of various electroless Ni–P alloy/multiwalled carbon nanotube composite films on an acrylonitrile butadiene styrene resin. Surf Coat Technol 205(10):3175–3181

Tengsuwan S, Ohshima M (2014) Environmentally benign electroless nickel plating using supercritical carbon-dioxide on hydrophilically modified acrylonitrile–butadiene–styrene. Appl Surf Sci 311:189–200

Dechasit P, Trakarnpruk W (2011) Ni electroless plating of ABS polymer by palladium and tin-free process. J Met Mater Min 21(2):19–27

Wang Z, Li Z, He Y, Wang Z (2011) Study of an environmentally friendly surface etching system of ABS for improving adhesion of electroless Cu film. J Electrochem Soc 158(11):D664–D670

Kim GG, Kang JA, Kim JH, K-y Lee, Kim SJ, Kim S-J (2007) Photocatalytic pretreatment of acrylonitrile–butadiene–styrene polymer for electroless plating. Scripta Mater 56(5):349–351

Di L, Liu B, Song J, Shan D, Yang D-A (2011) Effect of chemical etching on the Cu/Ni metallization of poly (ether ether ketone)/carbon fiber composites. Appl Surf Sci 257(9):4272–4277

Ferreira ODS, Stevens A, Schrauwen C (2009) Quantitative comparison of adhesion in metal-to-plastic systems. Thin Solid Films 517(10):3070–3074

Ma Z, Tan K, Kang E (2000) Electroless plating of palladium and copper on polyaniline films. Synth Met 114(1):17–25

Kulkarni MV, Elangovan K, Hemachandra RK (2013) Effects of electroplating on the mechanical properties of injection molded thermoplastics. Int J Plast Technol. doi:10.1007/s12588-013-9056-6

Vander Togt RT (2011) Bumper and process to bond ionomers to plastic. US Patent 4,999,227

Teixeira LAC, Santini MC (2005) Surface conditioning of ABS for metallization without the use of chromium baths. J Mater Process Technol 170(1):37–41

Shu Z, Wang X (2012) Environment-friendly Pd free surface activation technics for ABS surface. Appl Surf Sci 258(14):5328–5331

Bazzaoui M, Martins J, Bazzaoui E, Albourine A (2012) Environmentally friendly process for nickel electroplating of ABS. Appl Surf Sci 258(20):7968–7975

Tang X, Cao M, Bi C, Yan L, Zhang B (2008) Research on a new surface activation process for electroless plating on ABS plastic. Mater Lett 62(6):1089–1091

Skelly J (2008) Decorative plating processes for common plastic resins: resin selection as well as plastic part design is critical to matching the right finishing method with the intended application. Met Finish 106(6):61–65

Haba B, Sugai K, Morishige Y, Kishida S (1994) Large scale two-step selective aluminum CVD on laser patterned palladium lines. Appl Surf Sci 79:381–384

Chen Y, Reisman A, Turlik I, Temple D (1995) Cu CVD from copper (II) hexafluoroacetylacetonate II. Laser-assisted selective area deposition. J Electrochem Soc 142(11):3911–3918

Seeböck R, Esrom H, Charbonnier M, Romand M, Kogelschatz U (2001) Surface modification of polyimide using dielectric barrier discharge treatment. Surf Coat Technol 142:455–459

Tóth Z, Szörényi T, Toth A (1993) Ar+ laser-induced forward transfer (LIFT): a novel method for micrometer-size surface patterning. Appl Surf Sci 69(1):317–320

McCaskie JE, Tsiamis C (1985) Metal plating on plastics. US Patent 4,520,046

Yang C-Y (2012) Method for preparing electronic component-mounting device. US Patent App. 13/471,108

Hooke R (2014) Method of making shaped charges and explosively formed projectiles. US Patent 8,813,651

Hoyt R, Wrobel J, Cushing J, Jaster M, Voronka N, Frank S, Slostad J, Paritsky L (2014) Structures with internal microstructures to provide multifunctional capabilities. US Patent 14/462,541

Nath J, Shen Y, Nealis E (2014) Systems and methods for manufacturing passive waveguide components. US Patent App. 14/453,563

McCaskie JE (2006) Plating on plastics: a survey of mechanisms for adhering metal films to plastic surfaces. Met Finish 104(5):31–39

Mallory GO, Hajdu JB (1990) Electroless plating: fundamentals and applications. William Andrew, New York

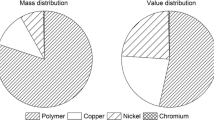

Arnold JR (2003) High quality copper-nickel-chromium plating on plastics: a continuous process and its challenges. Plat Surf Finish 91:355–379

Kulkarni MV, Elangovan K, Hemachandra Reddy K (2012) Improvements in impact resistance property of metal plated abs and Nylon6 thermoplastics. FS J Eng Res 1(1):31–33

Equbal AAKS (2014) Metallization on FDM parts using the chemical deposition technique. Coatings 4:574–586. doi:10.3390/coatings4030574

Tang X, Wang J, Wang C, Shen B (2011) A novel surface activation method for Ni/Au electroless plating of acrylonitrile–butadiene–styrene. Surf Coat Technol 206(6):1382–1388

Garcia A, Berthelot T, Viel P, Mesnage A, Jégou P, Nekelson F, Roussel S, Palacin S (2010) ABS polymer electroless plating through a one-step poly(acrylic acid) covalent grafting. ACS Appl Mater Interfaces 2(4):1177–1183

Kuzmik JJ (1990) Electroless plating: fundamentals and applications (Reprint Edition). In: Mallory GO, Hajdu JB (eds). The American Electroplaters and Surface Finishers Society, Orlanda, FL, pp 377–399

Hanna F, Hamid ZA, Aal AA (2004) Controlling factors affecting the stability and rate of electroless copper plating. Mater Lett 58(1):104–109

Equbal A, Sood AK (2014) Electroless plating of copper on different shaped ABS parts: a comparison. Int J Adv Mater Manuf Charact 4(1):32–41. doi:10.11127/ijammc.2014.03.05

Li D, Goodwin K, Yang C-L (2008) Electroless copper deposition on aluminum-seeded ABS plastics. J Mater Sci 43(22):7121–7131. doi:10.1007/s10853-008-3031-1

Liu H-P, Li N, Bi S-F, Li D-Y, Zou Z-L (2008) Effect of organic additives on the corrosion resistance properties of electroless nickel deposits. Thin Solid Films 516(8):1883–1889

Lu G, Li X, Jiang H (1996) Electrical and shielding properties of ABS resin filled with nickel-coated carbon fibers. Compos Sci Technol 56(2):193–200

Walsh F, De León CP, Kerr C, Court S, Barker B (2008) Electrochemical characterisation of the porosity and corrosion resistance of electrochemically deposited metal coatings. Surf Coat Technol 202(21):5092–5102

Agarwala RC, Agarwala V, Sharma R (2006) Electroless ni-p based nanocoating technology—a review. Synth React Inorg Met-Org Nano-Met Chem 36(6):493–515

Balaraju J, Narayanan TS, Seshadri S (2003) Electroless Ni–P composite coatings. J Appl Electrochem 33(9):807–816

Tzeng S-S, Chang F-Y (2001) EMI shielding effectiveness of metal-coated carbon fiber-reinforced ABS composites. Mater Sci Eng A 302(2):258–267

Charbonnier M, Romand M, Goepfert Y (2006) Ni direct electroless metallization of polymers by a new palladium-free process. Surf Coat Technol 200(16):5028–5036

Sahoo P, Das SK (2011) Tribology of electroless nickel coatings—a review. Mater Des 32(4):1760–1775

Sudagar J, Lian J, Sha W (2013) Electroless nickel, alloy, composite and nano coatings—a critical review. J Alloys Compd 571:183–204

Agarwala R, Agarwala V (2003) Electroless alloy/composite coatings: a review. Sadhana 28(3–4):475–493

Equbal A, Dixit NK, Sood AK (2013) Electroless plating on plastic. IJSER 4

Maul J, Frushour BG, Kontoff JR, Eichenauer H, Ott K-H, Schade C (2000) Polystyrene and styrene copolymers. In: Ullmann’s encyclopedia of industrial chemistry. Wiley, New York. doi:10.1002/14356007.a21_615.pub2

Federation BP (2015) A history of plastics. British Plastics Federation. http://www.bpf.co.uk/plastipedia/plastics_history/Default.aspx

Brickipedia (2015) Acrylonitrile butadiene styrene. Brickipedia. http://lego.wikia.com/wiki/Brickipedia:Brickipedians

Truss R, Chadwick G (1976) Tensile deformation behaviour of ABS polymers. J Mater Sci 11(1):111–117. doi:10.1007/BF00541081

Truss R, Chadwick G (1977) The fracture behaviour of ABS polymers. J Mater Sci 12:503–508. doi:10.1007/BF00540274

Bucknall C, Clayton D, Keast WE (1972) Rubber-toughening of plastics- Part 2 Creep mechanisms in HIPS/PPO blends. J Mater Sci 7(12):1443–1453. doi:10.1007/BF00574936

Kulich DM, Gaggar S, Lowry V, Stepien R (2004) Acrylonitrile–butadiene–styrene (ABS) polymers. Kirk-Othmer Encyclopedia of Chemical Technology

Moore J (1973) Acrylonitrile–butadiene–styrene (ABS)-a review. Composites 4(3):118–130

ABS material data sheet. teststandard.com/data_sheets/ABS_Data_sheet.pdf

Lifton VA, Lifton G, Simon S (2014) Options for additive rapid prototyping methods (3D printing) in MEMS technology. Rapid Prototyp J 20(5):403–412

Huang SH, Liu P, Mokasdar A, Hou L (2013) Additive manufacturing and its societal impact: a literature review. Int J Adv Manuf Technol 67:1191–1203. doi:10.1007/s00170-012-4558-5

Yuan L (2008) A preliminary research on development of a fiber-composite, curved FDM system. National University of Singapore

Wong KV, Hernandez A (2012) A review of additive manufacturing. ISRN Mech Eng. doi:10.5402/2012/208760

Yan XG, Gu PENG (1996) A review of rapid prototyping technologies and systems. Comput Aided Des 28(4):307–318

Diegel O, Reay S, Singamneni S, Withell A (2010) Tools for sustainable product design: additive manufacturing. J Sustain Dev 3(3):68–75

Stereolithography; S-PCHPi, http://spie.org/x91418.xml. Accessed 27 Sept 2015

3DSystems. 30 years of innovation. http://www.3dsystems.com/30-years-innovation. Accessed 27 Sept 2015

Crump SS (1992) Apparatus and method for creating three-dimensional objects. US Patent 5,121,329

Sachs EM, Haggerty JS, Cima MJ, Williams PA (1993) Three-dimensional printing techniques. US Patent 5,204,055

Gross BC, Erkal JL, Lockwood SY, Chen C, Spence DM (2014) Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal Chem. doi:10.1021/ac403397r

Chen S, Patel N, Schaffer D, Maharbiz M (2011) Trap and corral: a two-step approach for constructing and constraining dynamic cell contact events in differentiating progenitor cell populations. J Micromech Microeng 21(5):054027

Kannan S, Senthilkumaran D (2014) Assessment of mechanical properties of Ni-coated abs plastics using FDM process. IJMME-IJENS 14(3):30–35

Monzon MD, Diaz N, Benitez AN, Marrero MD, Hernandez PM (2010) Advantages of fused deposition modeling for making electrically conductive plastic. Int Conf Manuf Autom. doi:10.1109/ICMA.2010.36

Kannan S, Senthilkumaran D, Elangovan, K. (2013) Development of composite materials by rapid prototyping technology using FDM method. IEEE, 281–283

Chandrasekhar U, Venkatesh K, Elangovan K, Rangaswamy T (2011) Integrated use of rapid prototyping and metal plating techniques for development of micro air vehicles. IJEST 3(1):188–193

Equbal A, Sood AK (2015) Investigations on metallization in FDM build ABS part using electroless deposition method. J Manuf Process 19:22–31

Saleh N, Hopkinson N, Hague RJ, Wise S (2004) Effects of electroplating on the mechanical properties of stereolithography and laser sintered parts. Rapid Prototyp J 10(5):305–315

Kannan S, Senthilkumaran D (2014) Investigating the influence of electroplating layer thickness on the tensile strength for fused deposition processed ABS thermoplastics. IJET 6(2):1047–1052

Lurie KL, Smith GT, Khan SA, Liao JC, Ellerbee AK (2014) Three-dimensional, distendable bladder phantom for optical coherence tomography and white light cystoscopy. J Biomed Opt 19(3):036009

Stremsdoerfer G, Ghanem F, Saikali Y, Fares-Karam A (2003) Copper deposition by dynamic chemical plating. J Mater Sci 38(15):3285–3291. doi:10.1023/A:1025190022069

Weng D, Landau U (1995) Direct electroplating on nonconductors. J Electrochem Soc 142(8):2598–2604

Krishnan KH, John S, Srinivasan K, Praveen J, Ganesan M, Kavimani P (2006) An overall aspect of electroless Ni–P depositions—a review article. Metall Mater Trans A 37(6):1917–1926

Feldstein N (1981) Dispersions for activating non-conductors for electroless plating. US Patent 4,282,271

Feldstein N (1982) Electroless plating. US Patent 4,321,285

Equbal A, Equbal A, Sood AK (2014) Metallization on FDM processed parts using electroless procedure. Proc Mater Sci 6:1197–1206. doi:10.1016/j.mspro.2014.07.193

Kirman T (1972) Electroless nickel plating process for nonconductors. US Patent 3,684,572

Feldstein N (1976) Electroless plating process employing non-noble metal hydrous oxide catalyst. US Patent 3,993,799

Elmore G, Davis K (1969) Mechanism of bonding electroless metal to organic substrates. J Electrochem Soc 116(10):1455–1458

Abu-Isa IA (1973) Metal plating of polymeric surfaces. Polym-Plast Technol Eng 2(1):29–65

Metal plating of thermoplastics (1971). US Patent 3,620,804

Magallón-Cacho L, Pérez-Bueno J, Meas-Vong Y, Stremsdoerfer G, Espinoza-Beltrán F (2011) Surface modification of acrylonitrile-butadiene-styrene (ABS) with heterogeneous photocatalysis (TiO2) for the substitution of the etching stage in the electroless process. Surf Coat Technol 206(6):1410–1415

Krulik GA (1980) Method for electroless plating on nonconductive substrates using palladium/tin catalyst in aqueous solution containing a hydroxy substituted organic acid. US Patent 4,182,784

Daneshmand S, Aghanajafi C, Nadooshan AA (2010) The effect of chromium coating in RP technology for airfoil manufacturing. Sadhana 35(5):569–584

Gabe D (1977) Corrosion and protection of sintered metal parts. Powder Metall 20(4):227–231

Conlan W, Dutkewych O (1973) Pre-etch treatment of acrylonitrile-butadiene-styrene resins for electroless plating. US Patent 3,769,061

Weakley-Bollin SC (2010) The effect of injection molding conditions on the near-surface rubber morphology, surface chemistry and adhesion performance of semi-crystalline and amorphous polymers. University of Michigan, Ann Arbor

Beacom SE, Wedel RG (1970) Scanning electron microscopy of plastic surfaces as related to metal deposition. J Colloid Interface Sci 34(3):375–386

Kanani N (2004) Electroplating: basic principles, processes and practice. Elsevier, Oxford

Kato K (1968) Electron microscope studies on the etching of ABS mouldings for electroplating. Polymer 9:419–424

Dennis JK, Such TE (1993) Nickel and chromium plating. Elsevier, Amsterdam

Donovan LP, Timmer RJ (2002) Decorative chrome electroplate on plastics. US Patent 6,468,672

Hurley JL (1975) Decorative electroplates for plastics. US Patent 3,868,229

Narcus H (1979) Bright electroless plating process and plated articles produced thereby. US Patent 4,169,171

Gutzeit G, Talmey P (1958) Chemical nickel plating processes and baths therefor. US Patent 2,935,425

Jones RD (2005) Decoratively finished thermoplastic product and method for manufacturing same. US Patent App. 10/649,190

Metal plating of plastics (1970). US Patent 3,501,332

Marie OJ (1966) Method of electrodepositing a corrosion resistant nickel-chromium coating and products thereof. US Patent 3,282,810

Omura Y (1997) Process for catalyzation in electroless plating. US Patent 5,660,883

Odekerken JM (1972) Process for coating an object with a bright nickel/chromium coatin. US Patent 3,644,183

Eileen M (1972) Process for electroless plating of abs resins. US Patent 3,689,303

Paul T, Crehan WJ (1953) Process of chemical nickel plating. US Patent 2,658,839

Patel GN, Bolikal D, Patel HH (1992) Chromic acid free etching of polymers for electroless plating. US Patent 07/488,256

Brown SD, Ottavio ED, Kuzmik JJ, Grunwald JJ (1972) Method of treating plastic substrates and process for plating thereon. US Patent 3682786

Kuzmik J (1974) Preparation of plastic substrates for electroless plating and solutions therefor. US Patent 3,790,400

Roubal J, Korpiun J (1977) Pretreatment of plastic materials for metal plating. US Patent 06/701,585

Amelio WJ, Jung DY, Markovich V, Sambucetti CJ (1986) Process for manufacturing a concentrate of a palladium-tin colloidal catalyst. US Patent 09/831,008

Naruskevicius L, Rozovskis G, Vinkevicius J, Baranauskas M, Mobius A, Pies P (2004) Etching plastic surface under mild conditions, treating with solution containing cobalt, silver, tin, and/or lead salts having ph from about 7.5 to about 12.5, treating with sulfide solution, metallizing. US Patent US 6712948 B1

De De Minjer CH, vd Boom PFJ (1973) The nucleation with SnCl2–PdCl2 solutions of glass before electroless plating. J Electrochem Soc 120(12):1644–1650

Lindsay JH, La Sala J, Ghorashi HM (1983) Etching and bonding oxygen to acrylonitrile-butadiene-styrene terpolymer or polyphenylene ethers, vacuum deposition, followed by electrodeposition of metal films. US Patent 4,395,313

Cohen R, Meek R (1976) The chemistry of palladium–tin colloid sensitizing processes. J Colloid Interface Sci 55(1):156–162

Lindsay DJ, Feldstein N (1989) Activators for colloidal catalysts in electroless plating processes. US Patent 4,820,547

Comparison of sealing methods for FDM materials (2011). Stratasys

McCarthy DL, Williams CB (2012) Creating complex hollow metal geometries using additive manufacturing and electroforming. In: International Solid Freeform Fabrication Symposium, pp 108–120

Wang Y, Bian C, Jing X (2013) Adhesion improvement of electroless copper plating on phenolic resin matrix composite through a tin-free sensitization process. Appl Surf Sci 271:303–310

Wang G, Li N, Li D (2007) Effect of Pd ions in the chemical etching solution. J Univ Sci Technol Beijing Miner Metall Mater 14(3):286–289

Inagaki N, Kimura H (2009) Electroless copper plating on acrylonitrile butadiene styrene material surfaces without chromic acid etching and a palladium catalyst. J Appl Polym Sci 111(2):1034–1044

Arai S, Kanazawa T (2014) Electroless deposition and evaluation of Cu/multiwalled carbon nanotube composite films on acrylonitrile butadiene styrene resin. Surf Coat Technol 254:224–229

Li D, Yang C-L (2009) Acidic electroless copper deposition on aluminum-seeded ABS plastics. Surf Coat Technol 203(23):3559–3568

Helmut K, Eugen M-S (1972) Process for the pretreatment of plastic for the purpose of adhesive metallization. US Patent 3,702,285

Isa A, Vincent W (1974) Plating pre-treatment in acrylonitrile butadiene styrene. US Patent 3,847,648

Kang DH, Choi JC, Choi JM, Kim TW (2010) An environment-friendly surface pretreatment of ABS plastic for electroless plating using chemical foaming agents. Trans Electr Electron Mater 11(4):174–177

Zhao W, Ma Q, Li L, Li X, Wang Z (2014) Surface modification of ABS by photocatalytic treatment for electroless copper plating. J Adhes Sci Technol 28(5):499–511

Kim GG, Kang JA, Kim SJ, Kim SJ, Shin SH (2007) Improved adhesion to ABS plastics by a photocatalytic reaction. In: Materials science forum. Trans Tech Publication, Dürnten, pp 75–78

European Parliament and the Council, 2002/95/EC, 2003

WHO regional publications (2000), Air quality guidelines for Europe. 2nd edn. Copenhagen

Bazzaoui M, Martins J, Bazzaoui E, Albourine A, Wang R, Hong P-D (2013) A simple method for acrylonitrile butadiene styrene metallization. Surf Coat Technol 224:71–76

Parkinson R, Hart T, Electroplating on plasticts. NiDi Technical Series, Nickel Development Institute

Li Z, Li N, Yin L, He Y, Wang Z (2009) An environment-friendly surface pretreatment of ABS resin prior to electroless plating. Electrochem Solid-State Lett 12(12):D92–D95

European Parliament and the Council, 2005/90/EC, 2006

Yang Z, He Y, Li Z, Li N, Wang Z (2011) Adhesion improvement of ABS resin to electroless copper by H2SO4–MnO2 colloid with ultrasound-assisted treatment. J Adhes Sci Technol 25(11):1211–1221

Ma Q, Zhao W, Li X, Li L, Wang Z (2013) Study of an environment-friendly surface pretreatment of ABS-polycarbonate surface for adhesion improvement. Int J Adhes Adhes 44:243–249

Brandes M (2007) Advances in methods for plating on plastics tout advantages over conventional technologies: alternative plating procedures negate the need for chromic sulfuric acid, resulting in a more environmentally friendly process for electroplaters. Met Finish 105(3):35–40

Brocherieux A, Dessaux O, Goudmand P, Gengembre L, Grimblot J, Brunel M, Lazzaroni R (1995) Characterization of nickel films deposited by cold remote nitrogen plasma on acrylonitrile–butadiene–styrene copolymer App. Surf Sci 90:47–58

Tsuru Y, Mochinaga K, Ooyagi Y, Foulkes FR (2003) Application of vapor-deposited carbon and zinc as a substitute for palladium catalyst in the electroless plating of nickel. Surf Coat Technol 169:116–119

Tang X, Bi C, Han C, Zhang B (2009) A new palladium-free surface activation process for Ni electroless plating on ABS plastic. Mater Lett 63(11):840–842

Yen P-C (1995) Improved ABS plastic activating treatment for electroless copper plating. Polymer 36(17):3399–3400

Ono S, Naitoh K, Osaka T (1999) Initial propagation stage of direct copper plating on non-conducting substrates. Electrochim Acta 44(21):3697–3705

Gui-Xiang W, Ning L, Hui-Li H, Yuan-Chun Y (2006) Process of direct copper plating on ABS plastics. Appl Surf Sci 253(2):480–484

Acknowledgements

This research was supported by the Space Application Centre, ISRO, Government of India with the project ID ‘OGP 103.’

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Olivera, S., Muralidhara, H.B., Venkatesh, K. et al. Plating on acrylonitrile–butadiene–styrene (ABS) plastic: a review. J Mater Sci 51, 3657–3674 (2016). https://doi.org/10.1007/s10853-015-9668-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9668-7