Abstract

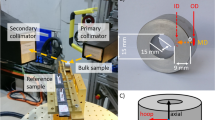

The full axisymmetric stress state of a granular material undergoing compaction in a cylindrical die has been measured using a technique based on neutron powder diffraction. This technique allowed the detailed distribution of stress to be measured in situ, deep within a copper powder inside a solid die. Four components of normal strain were measured over a radial cross section. These components consisted of the axial, radial, hoop and an off-axis strain in the axial-radial direction. This allowed for the reconstruction of the full axisymmetric stress tensor as a distribution over the radial cross section. Many interesting features were observed in this distribution, such as exponential decay of the axial stress (described by Janssen in Zeitschrift des Vereines duetscher Ingenieure 39:1045, 1895), and highly localised regions of high shear stress. The potential of this type of data in the validation of numerical models is discussed.

Similar content being viewed by others

References

Sinka I.C.: Modelling powder compaction. KONA 25, 4 (2007)

Chtourou H., Guillot M., Gakwaya A.: Modelling of the metal powder compaction process using the cap model. Part I. Experimental material characterisation and validation. Int. J. Solids Struct. 39, 1059 (2002)

Coube O., Riedel H.: Numerical simulation of metal powder die compaction with special consideration of cracking. Powder Metallur. 43, 123 (2000)

Cunningham J.C., Sinka I.C., Zavaliangos A.: Analysis of tablet compaction. I. Characterisation of mechanical behaviour of powder and powder/tooling friction. J. Pharmaceut. Sci. 93, 2022 (2004)

Han L.H., Elliot J.A., Bentham A.C., Mills A., Amidon G.E., Hancock B.C.: A modified Drucker–Prager Cap model for die compaction simulation of pharmaceutical powders. Int. J. Solids Struct. 45, 3088 (2008)

Hassanpour A., Ghadiri M.: Distinct element analysis and experimental evaluation of the Heckel analysis of bulk powder compression. Powder Technol. 141, 251 (2004)

Martin C.L., Bouvard D., Shima S.: Study of particle rearrangement during powder compaction by the discrete element method. J. Mech. Phys. Solids 51, 667 (2003)

Sheng Y., Lawrence C.J., Briscoe B.J., Thornton C.: Numerical studies of uniaxial powder compactioin processes by 3D DEM. Eng. Comput. 21, 304 (2004)

Nedderman R.M.: Statics and Kinematics of Granular Materials. Cambridge University Press, Cambridge (1992)

Doelker E., Massuelle D.: Benefits of die-wall instrumentation for research and development in tableting. Eur. J. Pharmaceut. Biopharmaceut. 58, 427 (2004)

Fitzpatrick, M.E., Lodini, A. (eds.): Analysis of Residual Stress by Diffraction Using Neutron and Synchrotron Radiation. Taylor and Francis, London (2003)

Kisi E.H., Howard C.J.: Applications of Neutron Powder Diffraction. Oxford University Press, Oxford (2008)

Bruel A., Kirstein O.: Residual stress diffractometer KOWARI at the Australian research reactor OPAL: status of the project. Phys. B Condens. Matter 385(386), 1040 (2006)

Bagi K.: Stress and strain in granular assemblies. Mech. Mater. 22, 165 (1996)

Christoffersen J., Mehrabadi M.M., Nemat-Nasser S.: A micromechanical description of granular material behaviour. J. Appl. Mech. 48, 339 (1981)

Fortin J., Millet O., de Saxce G.: Construction of an averaged stress tensor for a granular medium. Eur. J. Mech. A Solids 22, 567 (2003)

Goldhirsch I.: Stress, stress asymmetry and couple stress: from discrete particles to continuous fields. Granul. Matter 12, 239 (2010)

Weber J.: Recherches concernant les contraintes intergranulaires dans les milieux pulverulents. Bull. Liaison Physique et Chimie 20, 1–3 (1966)

Weinhart T., Thornton A.R., Luding S., Bokhove O.: From discrete particles to continuum fields near a boundary. Granul. Matter 14, 289 (2012)

Owen D.R., Hinton E.: Finite Elements in Plasticity. Pineridge Press, Swansea (1980)

Janssen H.A.: Versuche über Getreidedruck in Silozellen (Investigation of corn pressure in silo cells). Zeitschrift des Vereines duetscher Ingenieure 39, 1045 (1895)

Sperl M.: Experiments on corn pressure in silo cells—translation and comment of Janssen’s paper from 1895. Granul. Matter 8, 59 (2006)

Walker D.M.: An approximate theory for pressures and arching in hoppers. Chem. Eng. Sci. 21, 975 (1966)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wensrich, C.M., Kisi, E.H., Zhang, J.F. et al. Measurement and analysis of the stress distribution during die compaction using neutron diffraction. Granular Matter 14, 671–680 (2012). https://doi.org/10.1007/s10035-012-0366-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-012-0366-8