Abstract

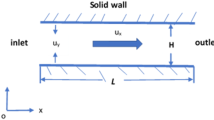

The anisotropic grooves in a microchannel induce spiral circulation around the flow axis. The stretch and fold of the streams result in a passive mixing. This article describes the effectiveness of induced crossflow, arising from the grooves, placed at the floor of the microchannel. The results from numerical simulation show the extent of local mixing achieved at various positions around the groove. The emphasis here is to understand the mixing when the two streams enter the channel, and displace air while flowing alongside each other. Microchannels with slanted grooves and staggered herringbone type grooves are considered here. The FLUENT 6.2 software and the Open FOAM software were used for the simulation. The latter was primarily utilized for tracking of the interface when a liquid slug displaced air from the micromixer. At a Reynold’s number of about 1.0, low velocity pockets could be identified near the two ends of the ridges. These pockets did not support crossflow and mixing. The herringbone type micromixer was found to have the best mixing effectiveness, when the advection dominates mixing. This advantage is mostly lost at the higher values of diffusivity, as a crossflow became less important for mixing. These observations were made when one of the streams is 1.5 times more viscous than the other, and the mixture-rule governed the viscosity of the mixed stream. When the liquid front enters the microchannel for the first time, the front had to displace air from the channel. At first, the upper part of the channel was swept. This was immediately followed by the sweeping of the groove-part in the floor. Higher hydraulic resistance in the grooves resulted in this non-uniform movement of the front. The co-flow of streams could either be continuous over the entire length of the channel, or in the form of slugs that maintained an interface with air. At a particular position in the channel, the extents of mixing were compared for the two modes of co-flow. The extent of mixing was found smaller in the slug, next to the interface with air. Lack of axial dispersion with preceding liquid stream seems to be the reason for this trend.

Similar content being viewed by others

References

Aubin J, Fletcher DF, Bertrand J, Xuereb C (2003) Characterization of the mixing quality in micromixers. Chem Eng Technol 26:1262–1270

Bessoth FG, deMello AJ, Manz A (1999) Microstructure for efficient continuous flow mixing. Anal Commun 36:213–215

Fu X, Liu S, Ruan X, Yang H (2006) Research on staggered oriented ridges static micromixers. Sens Actuators B 114:618–624

George PL, Frey P (2000) Mesh generation. Hermes, Lyon

Hong CC, Choi JW, Ahn CH (2004) A novel in-plane passive microfluidic mixer with modified Tesla structures. Lab Chip 4:109–119

Hu YH, Chang M, Lin KH (2006) A study of two fluids mixing in a helical-type micromixer. J Phys Conf Ser 48(1):531–536

Johnson TJ, Ross D, Locasio LE (2002) Rapid microfluidic mixing. Anal Chem 74(1):45–51

Kang TG, Kwon TH (2004) Colored particle tracking method for mixing analysis of chaotic micromixers. J Micromech Microeng 14:891–899

Kim SJ, Kwon TH (1996) Enhancement of mixing performance of single screw extrusion processes via chaoticflows. Adv Polymer Technol 15:41–69

Kockmann N (2008) Transport phenomena in micro process engineering. Springer, Berlin

Lin YC, Chung YC, Wu CY (2007) Mixing enhancement of the passive microfluidic mixer with J-shaped baffles in the tee channel. Biomed Microdevices 9:215–221

Liu RH, Stremler MA (2000) Passive mixing in a three-dimensional serpentine microchannel. J Microelectromech Sys 9:190–197

Liu YZ, Kim BJ, Sung HJ (2004) Two-fluid mixing in a microchannel. Int J Heat Fluid Flow 25(6):986–995

Nguyen NT, Wu Z (2005) Micromixers—a review. J Micromech Microeng 15:R1–R16

Ottino JM, Wiggins S (2004) Introduction: mixing in microfluidics. Phil Trans R Soc Lond 362:923–935

Schoeberl J (1997) NETGEN an advancing front 2d/3d-mesh generator based on abstract rules. Comput Vis Sci 1:41–52

Schonfeld F, Hardt S (2004) Simulation of helical flows in microchannels. AIChE J 50:771–778

Stroock AD, Dertinger SK, Ajdari A, Mezic I, Stone H, Whitesides GM (2002a) Chaotic mixer for mirochannels. Science 295(5555):647–651

Stroock AD, Dertinger SK, Whitesides GM, Ajdari A (2002b) Patterning flows using grooved surfaces. Anal Chem 74:5306–5312

Wang H, Iovenitt P, Harvey E, Masood S (2003) Numerical investigation of mixing in microchannels with patterned grooves. J Micromech Microeng 13:801–808

Yang JT, Huang KJ, Lin YC (2005) Geometric effects on fluid mixing in passive grooved micromixers. Lab Chip 5(10):1140–1147

Yang JT, Huang KJ, Tung KY, Lyu PC (2007) A chaotic micromixer modulated by constructive vortex agitation. J Micromech Microeng 17(10):2084–2092

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hasnain, S., Kumar, A. & Ganguly, S. Passive mixing of co-flowing slugs in grooved microchannels. Microsyst Technol 19, 17–24 (2013). https://doi.org/10.1007/s00542-012-1623-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-012-1623-9