Abstract

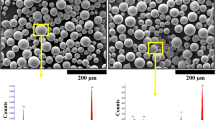

In this study, laser brazing of precipitation hardening nickel-based alloy (Inconel 718) and solid-solution nickel-based alloy (Inconel 600) with the nickel-based filler metal (BNi-2) using a 400-W pulsed Nd:YAG laser was investigated. A laser brazing process was performed at different gap distances. Microstructure and composition analysis of the filler metal and the brazed joints were examined by optical microscopy (OM) and scanning electron microscopy (SEM) equipped with an energy-dispersive X-ray spectroscopy (EDS). Mechanical properties of the brazed joints were measured in the form of micro hardness and tensile test. Results show that the filler metal consists of nickel solid solution, nickel-rich boride, and chromium-rich boride. The laser-brazed joints are mainly comprised of the nickel solid solution, nickel-rich boride in the center of the joints, and chromium-rich boride near the interface with substrates. The filler metal shows good wetting and spreading on Inconel 718 and Inconel 600 substrates in a laser brazing process. The average micro hardness for the filler metal was 550 HV compared to 500 HV for the laser-brazed joints. The tensile strength of the laser-brazed joints varied from 200 up to 500 MPa because of different gap distances.

Similar content being viewed by others

References

DuPont JN, Lippold JC, Kiser SD (2009) Welding metallurgy and weld ability of nickel-base alloys. Wiley, New Jersey

Davis JR (2000) ASM specialty handbook: nickel, cobalt, and their alloys. ASM International, Materials Park

AWS Committee on Brazing and Soldering (2002) Brazing handbook, 4th edn. Miami, United States of America

Schwartz MM (2003) Brazing, 2nd edn. ASM International, Materials Park

Wu X, Chandel RS, Li H, Seow HP, Wu S (2000) Induction brazing of Inconel 718 to Inconel X-750 using Ni-Cr-Si-B amorphous foil. J Mater Process Technol 104:34–43

Grushko B, Weiss BZ (1984) Structure of vacuum brazed BNi-5 joint of Inconel 718. Metall Trans A 15:609–620

Yeh MS, Chuang TH (1997) Effects of applied pressure on the brazing of super plastic Inconel 718 superalloy. Metall Trans A 28:1367–1376

Zaharinie T, Yusof F, Hamdi M, Ariga T, Moshwan R (2014) Effect of brazing temperature on the shear strength of Inconel 600 joint. Int J Adv Manuf Technol 73:1133–1140

Jalilvand V, Omidvar H, Shakeri HR, Rahimipour MR (2013) Microstructural evolution during transient liquid phase bonding of Inconel 738LC using AMS 4777 filler alloy. Mater Charact 75:20–28

Chung T, Kim J, Bang J, Rhee B, Nam D (2012) Microstructures of brazing zone between titanium alloy and stainless steel using various filler metals. Trans Nonferrous Metals Soc China 22:639–644

Arafin MA, Medraj M, Turner DP, Bocher P (2007) Transient liquid phase bonding of Inconel 718 and Inconel 625 with BNi-2: modeling and experimental investigations. Mater Sci Eng A 447:125–133

Wang FZ, Wang QZ, Yu BH, Xiao BL, Ma ZY (2011) Interface structure and mechanical properties of Ti(C, N)-based cermet and 17-4PH stainless steel joint brazed with nickel-base filler metal BNi-2. J Mater Process Technol 211:1804–1809

Ou CL, Liaw DW, Du YC, Shiue RK (2006) Brazing of 422 stainless steel using the AWS classification BNi-2 braze alloy. J Mater Sci 41:6353–6361

Lee YL, Shiue RK, Wu SK (2003) The microstructural evolution of infrared brazed Fe3Al by BNi-2 braze alloy. Intermetallics 11:187–195

Wu X, Li H, Chandel RS, Lan F, Seow HP (2000) Effect of mechanical vibration on TLP brazing with BNi-2 nickel-based filler metal. J Mater Sci Lett 19:319–321

Blue CA, Blue RA, Lin RY, Lei JF, Williams WD (1996) Joining of Hastelloy X to Inconel 718 using an infrared process. J Mater Process Technol 58:32–38

Khorram A, Ghoreishi M, Torkamany MJ, Bali MM (2014) Laser brazing of Inconel 718 alloy with a silver based filler metal. Opt Laser Technol 56:443–450

Khorram A, Ghoreishi M (2015) Comparative study on laser brazing and furnace brazing of Inconel 718 alloys with silver based filler metal. Opt Laser Technol 68:165–174

Lu F, Lu B, Tang X, Yao S (2008) Study of influencing factors and joint performance of laser brazing on zinc-coated steel plate. Int J Adv Manuf Technol 37:961–965

Li L, Tan C, Chen Y, Guo W, Mei C (2013) CO2 laser welding–brazing characteristics of dissimilar metals AZ31B Mg alloy to Zn coated dual phase steel with Mg based filler. J Mater Process Technol 213:361–375

Kai M, Zhishui Y, Peilei Z et al (2014) Influence of wire feeding speed on laser brazing zinc-coated steel with Cu-based filler metal. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6347-9

Khorram A, Ghoreishi M (2015) Numerical and experimental study of flowing and spreading of silver-based filler metal droplet on different substrates during laser brazing process. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7953-x

Saida K, Ohnishi H, Nishimoto K (2014) Laser brazing of TiAl intermetallic compound using precious brazing filler metals. Weld World. doi:10.1007/s40194-014-0173-4

Villars P, Prince A, Okamoto H (1995) Handbook of ternary alloy phase diagrams. ASM International, Metals Park, p 5508

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khorram, A., Fakhraei, O. & Torkamany, M.J. Laser brazing of Inconel 718 and Inconel 600 with BNi-2 nickel-based filler metal. Int J Adv Manuf Technol 88, 2075–2084 (2017). https://doi.org/10.1007/s00170-016-8897-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8897-5