Abstract

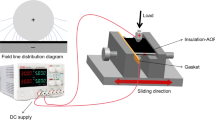

Friction tests of diffusion boride coatings were performed by rod-plate and rod-sleeve techniques at loads of 147-1960 N. It was shown that the Fe2B layer can demonstrate plastic deformation under the conditions. In the case of M11 (AISI) alloyed steel, diffusion boriding results in the extremely favorable hierarchical self-organization of defensive coatings and high wear resistance. The alloying of iron borides by chromium contributes to an increase in plasticity in these phases and a decrease in the coefficient of friction. The influence of the nature of the substrate and quenching treatment on the surface-relief characteristics before and after tribological tests, as well as on linear wear, has been determined.

Similar content being viewed by others

References

Guzanov, B.N., Kositsyn, S.V., and Pugacheva, N.B., Uprochnyayushchie zashchitnye pokrytiya v mashinostroenii (Reinforcing Protective Coatings in Engineering Industry), Ekaterinburg: Ural. Otd. Ross. Akad. Nauk, 2003.

Kolubaev, A.V., Tarasov, S.Yu., and Trusova, G.V., Structure and properties of one-phase boride coatings, Izv. Vuzov. Chernaya Metallurgiya, 1994, No. 7, pp. 49–51.

Tarasov, S.Yu., Trusova, G.V., Kolubaev, A.V., and Sizova, O.V., Structural properties of boride for triboengineering, Metal Sci. Heat Treat., 1995, vol. 37, pp. 257–260.

Pugacheva, N.B., Bykova, T.M., and Trushina, E.B., The steel-basis structure influence on the diffuzion boride coatings structure and properties, Uprochn. Tekhnol. Pokryt., 2013, No. 4, pp. 3–7.

Pugacheva, N.B., Zamaraev, L.M., Trushina, E.B., Gurchenko, T.M., and Zamjatin, A.N., The features of destruction by the diffusion boride coating on the carbon constructional steel in thermo-cycling under loading conditions, Uprochn. Tekhnol. Pokryt., 2011, No. 3, pp. 24–30.

Panin, V.E., Sergeev, V.P., and Panin, A.V., Nanostrukturirovanie poverkhnostnykh sloev konstruktsionnykh materialov i nanesenie nanostrukturnykh pokrytii (Nanostructuring of Surface Layers of Construction Materials and Superimposing of Nanostructure Coatings), Tomsk: Tomsk. Politekhn. Univ., 2010.

Tarasov, S.Yu., Belyaev, S.A., and Lerner, M.I., Wear resistance of structural steel in lubricants bearing metal nanopowders, Metal Sci. Heat Treat., 2005, vol. 47, pp. 560–565.

Kharlamov, V.V. and Pavlyshko, S.V., Smeshannaya smazka v tyazhelonagruzhennykh tribosopryazheniyakh skol’zheniya (Mixed Lubrication in Heavy-Loaded Sliding Tribocouplings), Ekaterinburg: Ural. Otd. Ross. Akad. Nauk, 2003.

Garkunov, D.N., Kargel’skii, I.V., and Polyakov, A.A., Izbiratel’nyi perenos v uzlakh treniya (Selective Transfer in Friction Units), Moscow: Transport, 1969.

Pugacheva, N.B., Pavlyshko, S.V., Trushina, E.B., and Zamyatin, A.N., Investigation of mass transfer during tribological interaction of alloyed steels, J. Fric. Wear, 2012, vol. 33, pp. 208–216.

Pugacheva, N.B., Pavlyshko, S.V., Trushina, E.B., and Zamyatin, A.N., Investigation of mass transfer during tribological interaction of alloyed steels, J. Fric. Wear, 2012, vol. 33, pp. 208–216.

Svoistva, poluchenie i primenenie tugoplavkikh soedinenii. Sprav. Izd. (Properties, Production and Application of Refractory Compounds), Kosolapova, T.Ya., Ed., Moscow: Metallurgiya, 1986.

Smirnov, S.V., Pugacheva, N.B., Tropotov, A.V., and Soloshenko, A.N., Resistance to deformation of structural constituents of a high-alloy brass, Phys. Met. Metallogr., 2001, vol. 91, pp. 210–215.

Smirnov, S.V., Pugacheva, N.B., Soloshenko, A.N., and Tropotov, A.V., Plastic deformation of a high-alloy brass, Phys. Met. Metallogr., 2002, vol. 93, pp. 584–593.

Smirnov, S.V., Pugacheva, N.B., Myasnikova, M.V., Matafonov, P.P., and Polkovnicov, T.V., Micromechanics of brass destruction and deformation, Phys. Mesomech., 2004, vol. 7,Suppl. 1–1, pp. 165–168.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.B. Pugacheva, E.B. Trushina, T.M. Bykova, 2014, published in Trenie i Iznos, 2014, Vol. 35, No. 6, pp. 708–717.

About this article

Cite this article

Pugacheva, N.B., Trushina, E.B. & Bykova, T.M. Research on the tribological properties of iron borides as diffusion coatings. J. Frict. Wear 35, 489–496 (2014). https://doi.org/10.3103/S1068366614060117

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366614060117