Abstract

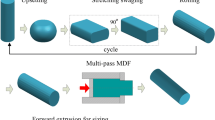

To research physical fields evolution and microstructures for compound extrusion of AZ31 Alloy, A kind of compound extrusion technology including extrusion and following shears for AZ31 magnesium billets have been explored. Three-dimensional finite element simulations of extruding AZ31 magnesium alloy billets into small rods at certain ram speed have been performed by compound extrusion with extrusion ratio 28 and channel angle 150°. Parameters including workpiece material characteristics and process conditions have been taken into consideration. High cumulative strains and low temperatures rise was the main reason for grain refinement during compound process. The observation results of microstructures and rod surface quality showed that the compound process effectively refine the grains of AZ31 magnesium and product magnesium alloy rods.

Similar content being viewed by others

References

Ravi Kumar, N.V., Blandin, J.J., Desrayaud, C., Montheillet, F., and Suery, N., Mater. Sci. Eng., Ser. A, 2003, vol. 359, p. 150.

Chandrasekaran, M. and John, Y.M.S., Mater. Sci. Eng., Ser. A, 2004, vol. 381, p. 308.

Hsiang, S.H. and Kuo, J.L., J. Mater. Process. Technol., 2003, vol. 140, p. 6.

Lapovok, R., Barnett, M.R., and Davies, C.H.J., J. Mat. Sci. Technol., 2004, vol. 146, p. 408.

Matsuyama, K., Miyahara, Y., Horita, Z., and Langdon, T.G., Acta Materialia, 2003, vol. 51, p. 3073.

Kiyoshi Matsubara, Yuichi Miyahara, Zenji Horita, Terence G. Langdon, Metallurg. Matter. Trans., Ser. A, 2004, vol. 35, p. 1734.

Gong, X., Kang, S.B., Li, S., and Cho, J.H., Mater. Design, 2009, vol. 30, p. 3345.

Orlov, D., Raab, G., Torbjorn, T., Lamark, Popov, M., and Estrin, Yu., Acta Materialia, 2011, vol. 59, p. 375.

Hu Hongjun, Zhang Dingfei, and Zhang JunPing, Trans. Nonfer. Met. Soc. China, 2010, vol. 20, p. 478.

Lapovok, R.Ye., Barnett, M.R., and Davies, C.H.J., J. Mater. Process. Technol., 2004, vol. 146, p. 408.

Siegert, K., Jäger, S., Vulcan, M., and Wizemann, C., Mater. Sci. Forum, 2005, vol. 488/489, p. 499.

Stalmann, A., Sebastian, W., Friedrich, H., Schumann, S., and Dröder, K., Adv. Eng. Mater., 2001, vol. 3, p. 969.

Gong, X., Li, H., Kang, S.B., Cho, J.H., and Li, S., Mater. Design, 2010, vol. 31, p. 1581.

Valiev, R.Z., Islamgaliev, R.K., and Alexandrov, I.V., Mater. Sci., 2000, vol. 45, p. 103.

Ogawa, N., Shiomi, M., and Osakada, K., Int. J. Mach. Tools Manu, 2002, vol. 42, p. 607.

Li, L., Zhou, J., and Duszczyk, J., J. Mater. Process. Technol., 2006, vol. 172, p. 372.

Author information

Authors and Affiliations

Additional information

The article is published in the original.

About this article

Cite this article

Hu, H.J., Fan, J.Z., Zhai, Z.Y. et al. Physical fields evolution and microstructures for compound extrusion of AZ31 magnesium alloy. Russ. J. Non-ferrous Metals 55, 254–262 (2014). https://doi.org/10.3103/S1067821214030067

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821214030067