Abstract

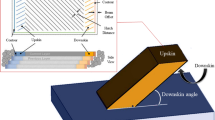

The paper addresses the simplest 3D model—a barrel made of parabolic and circular staves—for a diamond grain in the electroplated coating of dressing tools. It is shown that the proposed concepts of a diamond grain shape provide, on the one hand, an adequate description (including the quantitative one) the experimentally found relations between the parameters of an electroplated diamond coating and, on the other hand, a more detailed information in order to produce coatings with preset characteristics.

Similar content being viewed by others

References

Sheiko, M.N. and Skok, V.N., Grain shape as a factor governing the parameters of diamond electroplated coating of dressing tools. Part 1. The tool body dimensional allowance to accommodate diamond electroplated coating, J. Superhard Mater., 2015, vol. 37, no. 6, pp. 429–430.

Sheiko, M.N., Skok, V.N., and Pasichnyi M., Grain shape as a factor governing the parameters of diamond electroplated coating of dressing tools. Part 2. Actual grain–graphite form contact area and related characteristics as input data for calculating the conditions of diamond electroplated coating application by electroforming method, J. Superhard Mater., 2016, vol. 38, no. 1, pp. 47–50.

Baikalov, A.K., Vvedenie v teoriyu shlifovaniya materialov (Introduction to the Theory of Grinding), Kiev: Naukova Dumka, 1978.

Korolev, A.V. and Novoselov, Yu.K., Teoretiko-veroyatnostnye osnovy abrazivnoi obrabotki. Chast’ 1. Sostoyanie rabochei poverkhnosti instrumenta (Probability-theoretical fundamentals of abrasive machining. Part 1. Condition of Tool Working Surface), Saratov: Izd. Saratov. Univ., 1987.

Petasyuk, G.A. and Sirota, Yu.V., Analytical determination of the number of particles per carat for diamond powders on the basis of an extrapolation-affine 3D grain model, J. Superhard Mater., 2012, vol. 34, no. 3, pp. 200–208.

Sheiko, M.N., Skok, V.N., and Lubnin, A.G., Main characteristics of abrasive diamond layer in dressing tools, J. Superhard Mater., 2007, vol. 29, no. 4, pp. 75–78.

Hudson, D., Statistika dlya fizikov (Statistics for Physicists), Moscow: Mir, 1970.

Lavrentyev, M.A. and Shabat, B.V., Metody teorii funktsii kompleksnogo peremennogo (Methods of the Theory of Functions of Complex Variables), Moscow: Nauka, 1987.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.N. Sheiko, 2016, published in Sverkhtverdye Materialy, 2016, Vol. 38, No. 3, pp. 77–88.

About this article

Cite this article

Sheiko, M.N. Grain shape as a factor governing the parameters of diamond electroplated coating of dressing tools. Part 3. The simplest 3D model of a diamond grain—“A barrel made of parabolic and circular staves”. J. Superhard Mater. 38, 207–215 (2016). https://doi.org/10.3103/S1063457616030084

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457616030084