Abstract

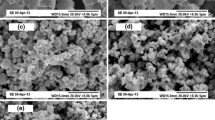

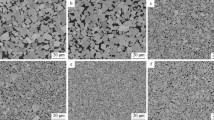

In the present paper cemented carbides with different grain sizes produced with WC powders obtained by the self-propagating high-temperature synthesis (SHS) were examined. Morphology, particle size distribution and chemical composition and of the SHS-powders were studied in detail. Microstructures of a submicron grade with 5% Co made from the near-nano WC powder obtained by the SHS and a standard submicron grade are similar with slightly more large WC grains in the sample made from the SHS WC powder. The mechanical properties of the ultrafine WC–5% Co grade made from the near-nano WC powder obtained by the SHS and its wear-resistance are comparable with those of the standard ultrafine grade. The microstructure of a medium-coarse WC–6% Co grade made from the medium-coarse SHS WC powder and its properties are comparable with those of the convenient medium-coarse carbide grade for percussive drilling. Results of laboratory performance tests on percussive drilling of the medium-coarse WC–6% Co grade obtained from both the SHS WC powder and conventionally fabricated WC powder indicate that their wear-resistance and performance toughness are very similar. Thus, it is established that high-quality WC–Co cemented carbides with different WC grain sizes varying from submicron to medium-coarse can be produced from the SHS WC powders.

Similar content being viewed by others

References

Konyashin, I., Comprehensive hard materials, in Cemented Carbides for Mining, Construction and Wear Parts, Sarin, V., Ed., Amsterdam: Elsevier, 2014, pp. 425–451.

Konyashin, I. and Ries, B., Wear damage of cemented carbides with different combinations of WC mean grain size and Co content: I. ASTM wear tests, Int. J. Refract. Met. Hard Mater., 2014, vol. 46, pp. 12–19.

Konyashin, I. and Ries, B., Wear damage of cemented carbides with different combinations of WC mean grain size and Co content: II. Laboratory performance tests on rock cutting and drilling, Int. J. Refract. Met. Hard Mater., 2014, vol. 45, pp. 230–237.

Kreimer, G.S., Strength of Hard Alloys, New York: Consultants Bureau, 1968.

Exner, H. and Gurland, J., A review of parameters influencing some mechanical properties of tungsten carbide–cobalt alloy, Powder Met., 1970, vol. 13, no. 1, pp. 13–31.

Guanghua, L., Jiangtao, L., and Kexin, C., Combustion synthesis of refractory and hard materials: A review, Int. J. Refract. Met. Hard Mater., 2013, vol. 39, pp. 90–102.

Merzhanov, A.G., History and recent developments in SHS: A review, Ceram. Int., 1995, vol. 21, no. 5, pp. 371–379.

Levashov, E.A., Rogachev, A.S., Yukhvid, V.I., and Borovinskaya, I.P., Fiziko-khimicheskie i tekhnologicheskie osnovy samorasprostranyayushchegosya vysokotemperaturnogo sinteza (Physicochemical and Technological Fundamentals of Self-Propagating High-Temperature Synthesis), Moscow: BINOM, 1999, pp. 110–115.

Zaytsev, A.A, Borovinskaya, I.P., Vershinnikov, V.I., Konyashin, I., Patsera, E.I., Levashov, E.A., and Ries, B., Near-nano and coarse-grain WC powders obtained by the self-propagating high-temperature synthesis and cemented carbides on their basis: I. Structure, composition and properties of WC powders, Int. J. Refract. Met. Hard Mater., 2015, vol. 50, pp. 146–151.

Lassner, E., Schreiner, M., and Lux, B., Influence of trace elements in cemented carbide production, Int. J. Refract. Met. Hard Mater., 1982, vol. 1, no. 3, pp. 97–102.

Ortner, H.M., The influence of trace elements on the properties of hard metals, in European Concerted Action COST 503, Valente, T., Ed., Brussels: European Commission, 1997, pp. 16–35.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Zaitsev, A.A., Vershinnikov, V.I., Konyashin, I. et al. High-quality cemented carbides on the basis of near-nano and coarse-grain WC powders obtained by self-propagating high-temperature synthesis (SHS). Int. J Self-Propag. High-Temp. Synth. 24, 152–160 (2015). https://doi.org/10.3103/S1061386215030139

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1061386215030139