Abstract

Steroid medication is used extensively in clinical applications and comprises a large and vital part of the pharmaceutical industry. However, the difficulty of separating 4-androstene-3,17-dione (AD) from 1,4-androstadiene-3,17-dione (ADD) restricts the application of the microbial transformation of phytosterols in the industry. A novel atmospheric and room temperature plasma (ARTP) treatment, which employs helium as the working gas, was used to generate Mycobacterium neoaurum mutants producing large amounts of AD. After treatment of cultures with ARTP, four mutants were selected using a novel screening method with a color assay. Among the mutants, M. neoaurum ZADF-4 was considered the best candidate for industrial application. When the fermentation medium contained 15 g/L phytosterols and was cultivated on a rotary shaker at 160 r/min at 30°C for 7 d, (6.28±0.11) g/L of AD and (0.82±0.05) g/L of ADD were produced by the ZADF-4 mutant, compared with (4.83±0.13) g/L of AD and (2.34±0.06) g/L of ADD by the original strain, M. neoaurum ZAD. Compared with ZAD, the molar yield of AD increased from 48.3% to 60.3% in the ZADF-4 mutant. This result indicates that ZADF-4 may have potential for industrial production of AD.

概要

目的

获得一株高产雄甾-4-烯-3,17-二酮 (AD) 的Mycobacterium neoaurum突变株。

创新点

获得了一株3-甾酮-Δ1-脱氢酶 (KSDD) 酶活缺陷型的高产AD的诱变菌株Mycobacterium neoaurumZADF-4, 并采用菌落显色法筛选KSDD酶活缺陷型M. neoaurum 突变株。

方法

(1) 诱变方法: 采用常压室温等离子体 (ARTP) 诱变技术来处理出发菌株M. neoaurum ZAD。ARTP诱变条件如下: 功率40W, 气流量12.5 L/min, 辐射距离1 cm, 样品体积10 μl, 辐射时间为60、90、120、150和180 s; 致死率统计优化后, 最适辐射时间为150 s, 致死率为90%~96%。 (2) 筛选方法: 将ARTP 诱变处理后的菌株点种在硝酸纤维滤膜上, 30°C培养2d, 然后将长有菌落的滤膜小心取出并漂浮在4 mg/ml二氯靛酚 (DCPIP) 溶液 (0.1 mmol/L磷酸缓冲液pH 7.0), 30°C培养1 d直到全部菌落染成蓝色。然后将该滤膜取出, 漂浮在250 mmol/L AD溶液 (2%甲醇和50 mmol/L Tris pH 7.0缓冲液), 室温放置15 min左右, 观察菌落颜色变化。KSDD在底物AD存在时会脱氢产生雄甾-1,4-二烯-3,17-二酮 (ADD) 和H+, H+可以使被DCPIP染成蓝色的菌株褪色。因此, 酶活缺陷型的菌株会仍保持蓝色, 而酶活高的菌株会褪色为黄色 (图3)。 (3) 对获得的潜在的高产AD菌株进行进一步的酶活检测以及产量验证, 以期获得最优的突变株。

结论

获得了4株具有潜在的高产AD能力的菌株, 其中, 最优的突变株ZADF-4的KSDD 酶活相较于出发菌株ZAD下降了81.2% (图4), 活性胶也证明其KSDD酶活相较于出发菌株下降明显 (图5)。薄层色谱法 (TLC) 和高效液相色谱法 (HPLC) 实验证明突变株ZADF-4中, AD的产量有了明显的提高 (图6和图7), 提高到了(6.28±0.11) g/L, AD/ADD提高到8:1, AD的摩尔产率达到60.3% (表1)。对出发菌株ZAD和突变株ZADF-4的ksdd基因进行克隆和序列比对, 发现ZADF-4 的ksdd 序列在5’端缺失9个核苷酸 (atgttctac), 导致3个氨基酸 (MFY) 的缺失; 还发生了两个点突变, 其中一个是无义突变 (g.15a>6t), 另一个是有义突变 (g.413c>404t), 并引起了相应位置上的氨基酸变化 (p.138S>135L)。上述的基因突变及其引起的氨基酸序列的变化可能是引起M. neoaurum ZADF-4中KSDD酶活降低及AD产量提高的主要原因。

Similar content being viewed by others

1 Introduction

Steroid drugs occupy an important position in the pharmaceutical industry and have been widely used in clinical applications (Choi et al., 1995; Zhang W.Q. et al., 2013). Three general processes are used worldwide for steroid production: isolation from natural sources, synthesis from non-steroidal starting materials, and partial synthesis from steroid raw materials that have been isolated from plants and animals. Biotransformation provides an alternative route to chemical synthesis for the production of steroid medicine intermediates and has been used extensively as a routine and economical process in the pharmaceutical industry (Wang et al., 2002; Huang et al., 2006; Zheng et al., 2011). Among the steroid drug intermediates, 4-androstene-3,17-dione (AD) and 1,4-androstadiene-3,17-dione (ADD) are the most important steroidal derivatives because they can be converted into a variety of steroidal drugs, such as sex hormones, adrenal cortical hormones, and other diverse steroids (van der Geize et al., 2000; 2001; Donova and Egorova, 2012). Recently, the microbial transformation of steroid intermediates from phytosterols has been reported. Several microorganisms including Mycobacterium, Rhodococcus, Nocardia, and Arthrobacter were found to have transformation capability (Bensasson et al., 1999; Wei et al., 2010a; Zhang W.Q. et al., 2013). Among them, Mycobacterium strains have been attracting increasing attention.

The microbial catabolic pathway of phytosterols has been well studied (Szentirmai, 1990; Donova and Egorova, 2012). The key reactions involved in structural steroid functionalization by Mycobacterium have been highlighted including sterol side-chain degradation, hydroxylation at various positions of the steroid core, and redox reactions (Donova and Egorova, 2012). Altogether, nine catabolic enzymes are involved in the steroid side-chain degradation pathway that functions in 14 consecutive enzymatic steps. These enzymes include ω-oxygenase, alcohol dehydrogenase, aldehyde dehydrogenase, acyl-SCoA dehydrogenase, methy-crotonyl carboxylase, acyl-SCoA enoyl hydratase, acyl-SCoA thiophorase, β-keto thiolase, and β-hydroxyacyl-SCoA dehydrogenase. In total, three molecules of reduced flavin adenine dinucleotide (FADH2), three of propionyl-SCoA, three of reduced form of nicotinamide-adenine dinucleotide (NADH), and one of acetic acid are formed, and the side-chain of one molecule of phytosterol is selectively removed (Szentirmai, 1990). The genome of Mycobacterium sp. VKM Ac-1817D has been reported to contain coding genes, including at least three genes of 3-ketosteroid-Δ1-dehydrogenase (KSDD, ksdd), five genes of 3-ketosteroid-9α-hydroxylase (KSH) subunit A (kshA), and one gene of KSH subunit B (kshB) (Bragin et al., 2013). In Mycobacterium, the microbial catabolic pathway of phytosterols is so complex that metabolic engineering with a rational design is very difficult. Recently, studies of Mycobacterium strains have reported that the solubility of phytosterols can be increased by adding hydroxypropyl-β-cyclodextrin (HP-β-CD) (Shen et al., 2012). This approach has been used for improving steroid biotransformation in aqueous media in strain ZJUVN-08 of M. neoaurum (Zhang X.Y. et al., 2013). In M. neoaurum strains, the productivity of transformation of sterols to sterones can be improved through enhancing the activity of cholesterol oxidases including cholesterol oxidase M1 (ChoM1) and ChoM2 (Yao et al., 2013). Our group has succeeded in cloning the KSDD coding gene, responsible for transforming AD to ADD, from M. neoaurum JC-12 and over-expressing it to construct a Bacillus subtilis biocatalyst (Zhang W.Q. et al., 2013). The cholesterol oxidases ChoM1 and ChoM2 from M. neoaurum JC-12 were highly expressed in the recombinant strains 168/pMA5-choM1 and 168/pMA5-choM2 of B. subtilis, respectively, and their activities were 5.2- and 7.3-fold higher, respectively, than those of the cholesterol oxidases in M. neoaurum JC-12 (Shao et al., 2014).

Microbial mutation breeding methods have been widely used in the fermentation industry, including the use of physical mutagens such as ultraviolet radiation and ion beams, and chemical mutagens such as sodium azide, diethyl sulphate, and ethyl methanesulphonate. Among these conventional mutation methods, issues of the health and safety of operators and mutation efficiency are always major concerns (Bhagwat and Duncan, 1998). Therefore, the development of an efficient breeding method for selecting highly productive AD mutants is highly desirable. In general, plasma is a partially or fully ionized gas and is sometimes known as the fourth and most energetic state of matter. Plasmas are usually classified as thermal or non-thermal. Usually, non-thermal plasmas are characterized by a palpable non-equilibrium between very hot electrons and cold heavy particles. Among the different types of atmospheric pressure non-equilibrium discharge (APNED) plasma sources, atmospheric and room temperature plasma (ARPT), which is driven by a radio frequency (RF) power supply with water-cooled, bare-metallic electrodes, has shown promise in applications in biotechnology (Zhang et al., 2014). In this context, the use of a novel mutation method such as ARTP has become increasingly popular due to its efficiency, safety, and environment-friendly nature (Hua et al., 2010; Wang et al., 2010; Li et al., 2014).

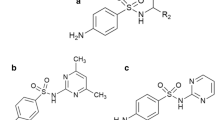

To obtain the target mutants, a rational and effective screening method, as well as an efficient breeding method is needed. Zhang X. et al. (2013) used a novel and effective screening method to isolate successfully a mutant of high acetoin-producing B. subtilis blocked in 2,3-butanediol dehydrogenase. The property of 2,6-dichlorophenolindophenol (DCPIP) enabling it to be easily reduced by NADH was used to isolate the promising mutant. It has been reported that DCPIP can be reduced by FADH2 (Leitner et al., 2001; Brugger et al., 2014). On this basis, we planned to screen for mutants of M. neoaurum blocked in KSDD, which performs the Δ1-dehydrogenation of the steroid polycyclic ring structure in the conversion of AD to ADD, accompanied by the transform of H+ (Fig. 1) (Szentirmai, 1990). If the enzyme activity of KSDD is inactivated or reduced, the molar ratio of AD/ADD in the production mixture will increase (Choi et al., 1995; Brzostek et al., 2005; Wei et al., 2010b).

Previously, our laboratory had isolated the ZAD strain of M. neoaurum (Fig. 2), which is capable of over-producing a mixture of AD and ADD. In this study, by using novel mutagenesis ARPT and screening methods, a KSDD deficient M. neoaurum mutant was isolated and the AD yield in the product mix was significantly increased. This work provides a promising candidate of M. neoaurum for industrial AD production as well as an extension of the H+-dependent dehydrogenase-deficient screening method.

2.1 Bacterial strains, culture method, and chemicals

Mycobacterium neoaurum ZAD was isolated from steroid-contaminated soil samples and stored in our lab. The seed medium contained 20 g/L glucose, 10 g/L tryptone, 6 g/L beef extract, and 10 g/L NaCl, adjusted to pH 8.0. The solid seed medium agar plates were prepared by adding 2% (0.02 g/ml) of agar. The fermentation medium contained: 20 g/L glucose, 3 g/L K2HPO4, 0.2 g/L MgSO4, 5×10−4 g/L MnCl2, 45 g/L hydroxypropyl-β-cyclodextrin (Shandong Binzhou Zhiyuan Bio-Technology Co., Ltd., China), 15 g/L phytosterol substrate, and 10 g/L soy peptone, adjusted to pH 8.0. Strains were inoculated at 30 °C on a rotary shaker at 160 r/min. The AD and ADD standards were obtained from Sigma-Aldrich Chemical Co. (Germany). The phytosterol substrate used was a sterol mixture containing more than 95% stigmasterol (Zhejiang Huzhou Biolily Biotechnology Co., Ltd., China). Ex Taq polymerase and restriction enzymes were acquired from TaKaRa Co., Ltd. (Dalian, China).

2.2 Mutagenesis with the ARTP biological breeding system and mutant selection

Mutation of ZAD using a pure helium plasma jet was carried out in the ARTP biological breeding system (supplied by Environment Biological Technology Laboratory, Department of Chemical Engineering, Tsinghua University, Beijing, China), which consisted of a coaxial type plasma generator, a gas supply control subsystem, a radio frequency (13.56 MHz) power supply, and a sample plate made of stainless steel. In this study, the operating parameters were as follows: the radio frequency (RF) power input was 40 W, the gas flow was 12.5 L/min, the distance between the plasma torch nozzle exit and the sample plate (D) was 1 cm, the temperature of the plasma jet was below 40 °C, and the plasma treatment time ranged from 60 to 180 s (Wang et al., 2010; Li et al., 2014; Zhang et al., 2014).

The original strain was cultivated in the seed medium at 30 °C and 160 r/min for 42–44 h. The cell concentration was adjusted to 1.0×106-1.0×107 ml−1 with sterile distilled water. A 10-μl aliquot of the above culture solution was applied to a sterilized sample plate and dried in sterile nitrogen for a few minutes (Wang et al., 2010). The bacterial samples were then exposed to the plasma jet downstream of the plasma torch nozzle exit for a given time. After the sample had been treated for a predetermined time, the plates were put into new tubes and washed with sterile distilled water to form the treated culture solution. The culture solution was then spread on the solid seed medium and cultivated at 30 °C for 2 d.

For selection of mutants, a filter assay was used for the detection of KSDD activity. During the working process of KSDD, a molecule of FADH2 is generated. The reducibility of FADH2 can degrade DCPIP effectively, while a mutant would lose the ability to generate FADH2 after the KSDD was inactivated or reduced (Szentirmai, 1990). KSDD, as a flavin-dependent oxidoreductase, has a reaction mechanism consisting typically of two half-reactions. In the reductive half-reaction, an electron donor substrate is reduced (Reaction 1). In the ensuing oxidative half-reaction, the reduced flavin is re-oxidized by the second substrate oxygen, yielding the oxidized prosthetic group and H2O2 (shown as reduced FADH2 in Reaction 2), or by alternative electron acceptors such as quinones, redox dyes, or chelated metal ions. The two-electron redox systems of the redox dye DCPIP are shown in Reaction 3 (Brugger et al., 2014), which is the theoretical basis for selecting the target strains. The related reactions are: (1) enzyme-FAD+ substrate→enzyme-FADH2+product; (2) FADH2+ O2→FAD+H2O2; (3) DCPIP+2e−+2H+→DCPIH2. Single colonies on seed agar plates were picked onto gridded sterile membrane filters (47 mm diameter, 0.45 μm pore size; Sartorius Stedim Biotech Co., Ltd., Germany), which were placed on the surface of seed plates and cultivated at 30 °C for about 2 d. Then the filters were carefully taken out, floated colony side up on 2 ml of a solution of 4 mg/ml DCPIP (Sigma) in 0.1 mol/L potassium phosphate buffer (pH 7.0) and incubated at 30 °C for about 1 d until all the colonies were dyed deep blue. Excess DCPIP was wiped off the filters with a dry sterile filter paper, and then the filters were floated on 3 ml of a 250 mmol/L solution of AD (2% methanol and 50 mmol/L Tris buffer, pH 7.0). KSDD-positive strains became yellow in about 15 min following the above treatment, while KSDD-deficient strains remained blue. The blue strains were then streak purified on seed agar plates (Nicholson, 2008; Zhang X. et al., 2013).

2.3 Cloning of the ksdd gene

The ksdd gene was cloned from the chromosomal DNA of mutants using the forward primer 5′-accggaattcgtgttctacatgactgcccagg-3′ and reverse primer 5′-gacggatcctcaggcctttccagcgagatg-3′. Polymerase chain reaction (PCR) amplification was performed using Ex Taq, a thermo stable polymerase, in Ex Taq buffer. The scheme of amplification included 35 cycles with the following conditions: initial denaturation at 95 °C for 4 min, followed by 35 cycles of denaturation (45 s at 95 °C), annealing (50 s at 63 °C), and extension (120 s at 72 °C), and a final elongation step (10 min at 72 °C). The desired band was excised and gel purified. The PCR reaction was performed using an automated thermocycler (Whatman Biometra, Gottingen, Germany).

2.4 Fermentation experiments and product assay

For AD fermentation, the cells from each seed medium plate were inoculated into 10 ml of seed medium broth and cultivated on a rotary shaker at 160 r/min at 30 °C for about 24 h. Then 1 ml of culture was transferred into 50 ml of seed medium at 160 r/min at 30 °C. After 24 h of culture growth, the seed culture was inoculated into 100 ml of fermentation medium and cultured for about 7 d. The inoculation volume was 10% of seed culture. Cell free supernatants were harvested every 24 h through centrifugation for 10 min at 10 000 r/min and then stored at −20 °C for further use.

The steroids extracted from the bioconversion (1 ml) by ethyl acetate were used for high performance liquid chromatography (HPLC) and thin-layer chromatography (TLC) analyses. For HPLC analysis, the products were diluted five times with ethyl acetate and filtered (nylon syringe filter, pore size 0.22 μm), then analyzed by HPLC with the following conditions: column, reversed phase Diamonsil C18 (Dikma Technologies, USA); column temperature, 30 °C; mobile phase, methanol-water (70:30, v/v); flow rate of mobile phase, 1 ml/min. Analytes were detected with UV simultaneously at 254 nm. For TLC analysis, sample extracts were spotted in 5-ìl aliquots onto TLC plates. Silica gel TLC plates with petroleum ether/ethyl acetate (6:4, v/v) as the solvent system were used. The TLC plates were dyed by 20% sulfuric acid at 100 °C for 10 min (Wei et al., 2010a; 2010b; Zhang W.Q. et al., 2013).

2.5 Preparation of cell-free extracts and KSDD enzyme activity assay

Cells were grown in fermentation medium for 7 d on a 500-ml rotary shaker at 30 °C and 160 r/min. Cell pellets (8 000 r/min, 10 min, 4 °C) were washed three times with 50 ml 50 mmol/L Tris-HCl buffer (pH 7.0). Cell pellets were suspended in Tris-HCl buffer (50 mmol/L Tris-HCl pH 7.0, 2 μg/ml phenylmethanesulfonyl fluoride (PMSF)) with a 1:2 (v/v) ratio, then the suspension was intermittently sonicated in an ice bath to disrupt the cells using 300 pulses of 7 s each (sonicated for 2 s and paused for 5 s) at 30% energy setting (300 W). Cell extracts were centrifuged for 30 min at 10 000 r/min in a Sigma 3K-15 centrifuge (Sigma, Germany) to remove the cell debris. The resulting supernatant of the culture was used for KSDD enzyme assays or stored at −20 °C.

KSDD activity was visualized by incubating native polyacrylate gel electrophoresis (PAGE) in 100 ml 50 mmol/L Tris-HCl buffer containing 3.1 mg phenazine methosulphate, 2.9 mg steroid (AD in 500 μl ethanol), and 41 mg nitroblueterazolium (NBT) dissolved in 500 μl 70% dimethylformamide. Staining was done for several hours until clear activity bands were visible. The reaction was stopped with 10% acetic acid. No KSDD activity stain was found in controls with ADD. Enzyme activities were measured spectrophotometrically at 30 °C using phenazine methosulfate (PMS) and DCPIP. The reaction mixture (1 ml) consisted of 50 mmol/L Tris-HCl buffer (pH 7.0), 1.5 mmol/L PMS, 40 μmol/L DCPIP, an appropriate concentration of the supernatant or cell extract, and 250 mmol/L AD in 2% methanol. Activity is expressed as U/mg of protein; 1 U is defined as the reduction of 1 μmol/min DCPIP (ζ600 nm=18.7× 103 L/(mol·cm)). No activity was detected in reaction mixture lacking AD (Wei et al., 2010b; Zhang W.Q. et al., 2013).

3 Results

3.1 Mutagenesis and mutant selection

It has been reported that ARTP has a higher positive genotoxic response than traditional mutation methods, making it a potentially effective mutation breeding strategy (Hua et al., 2010; Wang et al., 2010; Li et al., 2014; Zhang et al., 2014). In this study, ARTP-irradiation was used for inducing random mutations, and high AD-producing M. neoaurum mutants were selected later. M. neoaurum cells were treated with the helium-based ARTP for 60, 90, 120, 150, or 180 s, and the optimal exposure time was determined to be 150 s with lethality from 90% to 96% (data not shown). Therefore, the exposure time employed in subsequent studies was set at 150 s. After ARTP mutation, high KSDD-activity strains were converted to yellow by the filter assay using the treatments described above, while four KSDD-deficient mutants that retained a blue color were isolated. These mutants were then streak purified for further characterization. Fig. 3 shows the screening process used to isolate ZADF-4 (one of the reduced KSDD mutant strains). After the first screening process, a single colony (Fig. 3a) of ZADF-4 was separated and checked by repeating the filter assay to obtain a pure mutant (Fig. 3b). Floating the filter on the AD solution clearly showed that ZADF-4 remained blue, while KSDD-positive strains quickly turned yellow.

3.2 Enzyme activity assay of KSDD

KSDD plays a key role in the process of transforming AD to ADD, and therefore KSDD activity is vital for metabolic flux distribution involved in AD and ADD productions. The activity of KSDD in the original strain was (3.24±0.05) U/mg, while of the four mutants with reduced KSDD activity, ZADF-4 showed the lowest activity ((0.61±0.02) U/mg; Fig. 4), a reduction of about 81.2%. It was obvious that the activity of KSDD was reduced and the proportion of AD increased significantly (Fig. 4). A crude cell extract was prepared and assayed by native PAGE as described above. Staining for KSDD activity on native PAGE gels loaded with extracts of ZAD clearly revealed a stronger activity band than the KSDD deficient mutant, ZADF-4 (Fig. 5).

3.3 Product analyses of M. neoaurum ZAD and ZADF-4

It has been reported that fast growing mycobacteria can degrade natural sterols and use them as a source of carbon and energy (Nagasawa et al., 1969; Biggs et al., 1977). Preliminary fermentation of these mutants was studied using the methods described above, and the products were detected after 3 d. The fermentation results for ZAD and ZADF-4 showed that the highest AD production was observed on Day 7 (Fig. 6). TLC analysis revealed that when cultured in fermentation medium the original strain could transform phytosterols efficiently and accumulate AD and ADD simultaneously, while the mutant ZADF-4 reduced the proportion of ADD in the product mixture significantly (Fig. 7a). The HPLC result for ZADF-4 showed that this strain accumulated AD as the main product, with AD/ADD molar yields of about 8:1 (Fig. 7b). In the transformation experiments with shake flasks, ZADF-4 exhibited an increased product ratio of AD:ADD compared with the original strain (Table 1). Among the four mutants, ZADF-4 achieved the highest ratio of AD in the product mixtures (Fig. 4 and Table 1; the specific data of the other mutants are not shown). The ability to transform phytosterols to AD was improved noticeably in ZADF-4, and it was then selected as a promising AD producer for further studies.

TLC and HPLC analyses of fermentation products

(a) TLC analysis of transformation products. Lane 1: standard sample of AD; Lane 2: standard sample of ADD; Lane 3: standard mixture of AD and ADD; Lane 4: products from 7 d cultures of M. neoaurum ZADF-4; Lane 5: products from 7 d cultures of ZAD. (b) HPLC analysis of M. neoaurum ZADF-4 from 7 d cultures 1 2 3 4 5 (a)

3.4 Sequencing of the mutant ksdd gene

After screening, ZADF-4 was chosen as the most promising candidate high AD-producing strain. The ksdd gene of ZADF-4 was amplified and sequenced, and compared with that of ZAD (GenBank accession number for ksdd in M. neoaurum ZAD: Banklt1783760, Mycobacterium KP284440). In the 5′-terminal sequence of ksdd, the mutant ZADF-4 is missing nine nucleotides (atgttctac) compared with ZAD. Therefore, the translation of KSDD in ZADF-4 is reduced by three amino acids (MFY). Moreover, there are two point mutations in the ksdd gene of ZADF-4, one of which is a silent mutation (g.15a>6t), while the other signal base change (g.413c>404t) resulted in a missense mutation (p.138S>135L) in the translation of KSDD. The mutations caused amino acid changes, which ultimately caused the reduction of KSDD activity in ZADF-4.

4 Discussion

In recent years, with the increasing consumption of steroid drugs, the use of biotransformation in the production of steroid medicine intermediates has attracted more attention because it is highly efficient, safe, and environmentally friendly (Fernandes et al., 2003; Swizdor et al., 2012). The strain of ZAD stored in our lab could efficiently transform phytosterols to AD and ADD, the most important steroid intermediates. However, due to their structural similarity, the presence of AD and ADD in the product mix significantly complicates their purification and decreases their final yields, thus impeding further commercial application of many promising strains (van der Geize et al., 2001; Wei et al., 2014). The possibility of using ZAD in industry would be enhanced if the proportion of AD or ADD could be enhanced significantly. In M. neoaurum NwIB-04, the enzyme KSDD has been augmented through genetic manipulation to obtain mutants with good ADD production and to overcome the difficulty of separating AD from ADD (ADD 4.94 g/L, AD 0.096 g/L), a key constraint to the microbial transformation of phytosterols in industry (Wei et al., 2010b). For the M. neoaurum strain ZJUVN-08, under optimal process conditions, the molar ratio of HP-β-CD to phytosterol is 1.92:1, 8.98 g/L phytosterol, at 120 h of incubation time, and the maximum AD yield is 5.96 g/L (Zhang X.Y. et al., 2013). Living cells of Mycobacterium sp. NRRL B-3683 were immobilized by adsorption on activated alumina to produce ADD from cholesterol. When glucose and peptone were added to the reaction medium, the maximum productivity of ADD was about 0.19 g/L per day with a molar conversion rate of 77% when 1.0 g/L of cholesterol was added (Lee and Liu, 1992). The strain of Mycobacterium sp. VKM Ac-1815D was found to convert ergosterol and its 3-acetate mainly to AD. The molar yield of AD from 12.06 mmol/L (4.78 g/L) ergosterol reached 58.6% after 120 h. ADD and 20-hydroxymethylpregn-4-ene-3-one (HMP) were formed as minor products (Dovbnya et al., 2010). Relevant studies using Rhodococcus erythropolis have been reported. However, this study focuses on breeding high AD-producing M. neoaurum strains by isolating KSDD-deficient mutants.

Fortunately, in this study, a mutant of M. neoaurum, ZADF-4, with high AD production was obtained using the ARTP mutation technique and a novel and effective screening method. By using the ARTP mutation technique to modify the gene ksdd encoding KSDD, a critical enzyme involved in steroid metabolism, the composition of the fermentation products was changed. In fermentation experiments, the strain ZADF-4 converted 15 g/L of soybean phytosterols to (6.28±0.11) g/L AD (molar yield of 60.3%) and (0.82±0.05) g/L ADD on Day 7, compared with only (4.83±0.13) g/L AD (molar yield of 48.3%) and (2.34±0.06) g/L ADD by the original strain (Table 1). Compared with the original strain, the mutant ZADF-4 not only improved the proportion of AD in the total product mix, but also increased the production of AD. Therefore, it could be a promising candidate for accumulating AD for industrial applications.

5 Conclusions

In the present work, we obtained a high ADproducing mutant of M. neoaurum, ZADF-4, using the ARTP mutation technique and an H+-dependent dehydrogenase-deficient screening method. The mutant was identified as the best candidate for industrial application. Compared with the original strain, the accumulation and proportion of AD were significantly enhanced. Therefore, the study successfully provided a mutant, ZADF-4, which could be used as a promising candidate for accumulating AD for industrial applications.

Compliance with ethics guidelines

Chao LIU, Xian ZHANG, Zhi-ming RAO, Ming-long SHAO, Le-le ZHANG, Dan WU, Zheng-hong XU, and Hui LI declare that they have no conflict of interest.

This article does not contain any studies with human or animal subjects performed by any of the authors.

References

Bensasson, C.S., Hanson, J.R., Le Huerou, Y., 1999. The microbiological hydroxylation of 3α,5-cycloandrostanes by Cephalosporium aphidicola. Phytochemistry, 52(7): 1279–1282. [doi:10.1016/S0031-9422(99)00415-X]

Bhagwat, B., Duncan, E.J., 1998. Mutation breeding of banana cv. Highgate (Musa spp., AAA Group) for tolerance to Fusarium oxysporum f. sp. cubense using chemical mutagens. Sci. Hortic. (Amsterdam), 73(1):11–22. [doi:10.1016/S0304-4238(97)00141-6]

Biggs, C.B., Pyke, T.R., Wovcha, M.G., et al., 1977. Microbial Transformation of Steroids. US Patent 4062729.

Bragin, E.Y., Shtratnikova, V.Y., Dovbnya, D.V., et al., 2013. Comparative analysis of genes encoding key steroid core oxidation enzymes in fast-growing Mycobacterium spp. strains. J. Steroid Biochem. Mol. Biol., 138:41–53. [doi:10.1016/j.jsbmb.2013.02.016]

Brugger, D., Krondorfer, I., Zahma, K., et al., 2014. Convenient microtiter plate-based, oxygen-independent activity assays for flavin-dependent oxidoreductases based on different redox dyes. Biotechnol. J., 9(4):474–482. [doi:10.1002/biot.201300336]

Brzostek, A., Sliwinski, T., Rumijowska-Galewicz, A., et al., 2005. Identification and targeted disruption of the gene encoding the main 3-ketosteroid dehydrogenase in Mycobacterium smegmatis. Microbiology, 151(7):2393–2402. [doi:10.1099/mic.0.27953-0]

Choi, K.P., Murooka, Y., Molnár, I., 1995. Secretory overproduction of Arthrobacter simplex 3-ketosteroid Δ1-dehydrogenase by Streptomyces lividans with a multi- copy shuttle vector. Appl. Microbiol. Biotechnol., 43(6): 1044–1049. [doi:10.1007/BF00166923]

Donova, M.V., Egorova, O.V., 2012. Microbial steroid transformations: current state and prospects. Appl. Microbiol. Biotechnol., 94(6):1423–1447. [doi:10.1007/s00253-012-4078-0]

Dovbnya, D.V., Egorova, O.V., Donova, M.V., 2010. Microbial side-chain degradation of ergosterol and its 3-substituted derivatives: a new route for obtaining of deltanoids. Steroids, 75(10):653–658. [doi:10.1016/j.steroids.2010.04.001]

Fernandes, P., Cruz, A., Angelova, B., et al., 2003. Microbial conversion of steroid compounds: recent developments. Enzyme Microb. Technol., 32(6):688–705. [doi:10.1016/S0141-0229(03)00029-2]

Hua, X.F., Wang, J., Wu, Z.J., et al., 2010. A salt tolerant Enterobacter cloacae mutant for bioaugmentation of petroleum- and salt-contaminated soil. Biochem. Eng. J., 49(2):201–206. [doi:10.1016/j.bej.2009.12.014]

Huang, C.L., Chen, Y.R., Liu, W.H., 2006. Production of androstenones from phytosterol by mutants of Mycobacterium sp. Enzyme Microb. Technol., 39(2):296–300. [doi:10.1016/j.enzmictec.2005.10.017]

Lee, C.Y., Liu, W.H., 1992. Production of androsta-1,4-diene-3,17-dione from cholesterol using immobilized growing cells of Mycobacterium sp. NRRL B-3683 adsorbed on solid carriers. Appl. Microbiol. Biotechnol., 36(5):598–603. [doi:10.1007/BF00183235]

Leitner, C., Volc, J., Haltrich, D., 2001. Purification and characterization of pyranose oxidase from the white rot fungus Trametes multicolor. Appl. Environ. Microbiol., 67(8):3636–3644. [doi:10.1128/AEM.67.8.3636-3644.2001]

Li, H.G., Luo, W., Wang, Q., et al., 2014. Direct fermentation of gelatinized cassava starch to acetone, butanol, and ethanol using Clostridium acetobutylicum mutant obtained by atmospheric and room temperature plasma. Appl. Biochem. Biotechnol., 172(7):3330–3341. [doi:10.1007/s12010-014-0765-x]

Nagasawa, M., Bae, M., Tamura, G., et al., 1969. Microbial transformation of sterols. Agric. Biol. Chem., 33(11): 1644–1650. [doi:10.1271/bbb1961.33.1644]

Nicholson, W.L., 2008. The Bacillus subtilis ydjL (bdhA) gene encodes acetoin reductase/2,3-butanediol dehydrogenase. Appl. Environ. Microbiol., 74(22):6832–6838. [doi:10.1128/AEM.00881-08]

Shao, M.L., Rao, Z.M., Zhang, X., et al., 2014. Bioconversion of cholesterol to 4-cholesten-3-one by recombinant Bacillus subtilis expressing choM gene encoding cholesterol oxidase from Mycobacterium neoaurum JC-12. J. Chem. Technol. Biotechnol., in press. [doi:10.1002/jctb.4491]

Shen, Y.B., Wang, M., Li, H.N., et al., 2012. Influence of hydroxypropyl-β-cyclodextrin on phytosterol biotransformation by different strains of Mycobacterium neoaurum. J. Ind. Microbiol. Biotechnol., 39(9):1253–1259. [doi:10.1007/s10295-012-1130-0]

Swizdor, A., Kolek, T., Panek, A., et al., 2012. Selective modifications of steroids performed by oxidative enzymes. Curr. Org. Chem., 16(21):2551–2582. [doi:10.2174/138527212804004625]

Szentirmai, A., 1990. Microbial physiology of sidechain degradation of sterols. J. Ind. Microbiol., 6(2):101–115. [doi:10.1007/BF01576429]

van der Geize, R., Hessels, G.I., van Gerwen, R., et al., 2000. Targeted disruption of the kstD gene encoding a 3-ketosteroid Δ1-dehydrogenase isoenzyme of Rhodococcus erythropolis strain SQ1. Appl. Environ. Microbiol., 66(5):2029–2036. [doi:10.1128/AEM.66.5.2029-2036.2000]

van der Geize, R., Hessels, G.I., van Gerwen, R., et al., 2001. Unmarked gene deletion mutagenesis of kstD, encoding 3-ketosteroid Δ1-dehydrogenase, in Rhodococcus erythropolis SQ1 using sacB as counter-selectable marker. FEMS Microbiol. Lett., 205(2):197–202. [doi:10.1111/j.1574-6968.2001.tb10947.x]

Wang, L.Y., Huang, Z.L., Li, G., et al., 2010. Novel mutation breeding method for streptomyces avermitilis using an atmospheric pressure glow discharge plasma. J. Appl. Microbiol., 108(3):851–858. [doi:10.1111/j.1365-2672.2009.04483.x]

Wang, Z.F., Huang, Y.L., Rathman, J.F., et al., 2002. Lecithin-enhanced biotransformation of cholesterol to androsta-1,4-diene-3,17-dione and androsta-4-ene-3,17-dione. J. Chem. Technol. Biotechnol., 77(12):1349–1357. [doi:10.1002/jctb.728]

Wei, W., Fan, S.Y., Wang, F.Q., et al., 2010a. A new steroid transforming strain of Mycobacterium neoaurum and cloning of 3-ketosteroid 9-α-hydroxylase in NwIB-01, Appl. Biochem. Biotechnol., 162(5):1446–1456. [doi:10.1007/s12010-010-8919-y]

Wei, W., Wang, F.Q., Fan, S.Y., et al., 2010b. Inactivation and augmentation of the primary 3-ketosteroid-Δ1-dehydrogenase in Mycobacterium neoaurum NwIB-01: biotransformation of soybean phytosterols to 4-androstene-3,17-dione or 1,4-androstadiene-3,17-dione. Appl. Environ. Microbiol., 76(13):4578–4582. [doi:10.1128/AEM.00448-10]

Wei, W., Fan, S.Y., Wang, F.Q., et al., 2014. Accumulation of androstadiene-dione by overexpression of heterologous 3-ketosteroid Δ1-dehydrogenase in Mycobacterium neoaurum NwIBib-01. World J. Microbiol. Biotechnol., 30(7):1947–1954. [doi:10.1007/s11274-014-1614-3]

Yao, K., Wang, F.Q., Zhang, H.C., et al., 2013. Identification and engineering of cholesterol oxidases involved in the initial step of sterols catabolism in Mycobacterium neoaurum. Metab. Eng., 15:75–87. [doi:10.1016/j.ymben.2012.10.005]

Zhang, W.Q., Shao, M.L., Rao, Z.M., et al., 2013. Bioconversion of 4-androstene-3,17-dione to androst-1,4-diene-3,17-dione by recombinant Bacillus subtilis expressing ksdd gene encoding 3-ketosteroid-Δ1-dehydrogenase from Mycobacterium neoaurum JC-12. J. Steroid Biochem. Mol. Biol., 135:36–42. [doi:10.1016/j.jsbmb.2012.12.016]

Zhang, X., Zhang, R.Z., Yang, T.W., et al., 2013. Mutation breeding of acetoin high producing Bacillus subtilis blocked in 2,3-butanediol dehydrogenase. World J. Microbiol. Biotechnol., 29(10):1783–1789. [doi:10.1007/s11274-013-1339-8]

Zhang, X., Zhang, X.F., Li, H.P., et al., 2014. Atmospheric and room temperature plasma (ARTP) as a new powerful mutagenesis tool. Appl. Microbiol. Biotechnol., 98(12): 5387–5396. [doi:10.1007/s00253-014-5755-y]

Zhang, X.Y., Peng, Y., Su, Z.R., et al., 2013. Optimization of biotransformation from phytosterol to androstenedione by a mutant Mycobacterium neoaurum ZJUVN-08. J. Zhejiang Univ.-Sci. B (Biomed. & Biotechnol.), 14(2): 132–143. [doi:10.1631/jzus.B1200067]

Zheng, J.H., Wei, C.D., Zhao, L.N., et al., 2011. Combining blue native polyacrylamide gel electrophoresis with liquid chromatography tandem mass spectrometry as an effective strategy for analyzing potential membrane protein complexes of Mycobacterium bovis bacillus Calmette-Guérin. BMC Genomics, 12:40. [doi:10.1186/1471-2164-12-40]

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Basic Research Program (973) of China (No. 2012CB725202), the National High-Tech R & D Program (863) of China (No. 2011AA02A211), the National Natural Science Foundation of China (No. 21276110), the Fundamental Research Funds for the Central Universities (Nos. JUSRP51306A and JUSRP11545), the National 111 Project of China’s Higher Education (No. 111-2-06), the Program of the Key Laboratory of Industrial Biotechnology, Ministry of Education, China (No. KLIB-KF201406), and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), China

ORCID: Chao LIU, http://orcid.org/0000-0002-5931-1722

Rights and permissions

About this article

Cite this article

Liu, C., Zhang, X., Rao, Zm. et al. Mutation breeding of high 4-androstene-3,17-dione-producing Mycobacterium neoaurum ZADF-4 by atmospheric and room temperature plasma treatment. J. Zhejiang Univ. Sci. B 16, 286–295 (2015). https://doi.org/10.1631/jzus.B1400274

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.B1400274

Key words

- Mycobacterium neoaurum

- Atmospheric and room temperature plasma (ARTP)

- Mutation breeding

- 4-Androstene-3,17-dione (AD)

- 1,4-Androstadiene-3,17-dione (ADD)