Abstract

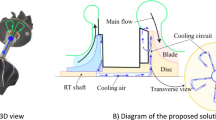

Thermal fatigue (TF) is one of the most important factors that influence turbine’s life. This paper establishes a 3D solid-fluid coupling model for a steady temperature analysis of a high-pressure turbine nozzle at different turbine inlet gas total temperatures (TIGTTs). The temperature analysis supplies the temperature load for subsequent 3D finite element analysis to obtain the strain values. Following this, the prediction of the TF life is made on the basis of equivalent strain range. The results show that the strain increases with TIGTT, and the predicted TF life decreases correspondingly. This life prediction was confirmed by one TF test.

Similar content being viewed by others

References

Akay, H.U., Liu, Y., Rassaian, M., 2003. Simplification of finite element models for thermal fatigue life prediction of PBGA packages. Journal of Electronic Packaging, 125(3):347–353. [doi:10.1115/1.1569956]

Angelis, G. D., Palomba, F., 2004. The Reliability Improvement of a Conventional Cast Iron Exhaust Manifold for a Small Size Gasoline Engine. ASME Internal Combustion Engine Division Fall Technical Conference Long Beach, California, USA.

Angileri, V., Bonavolontà, R., Durando, M., Garganese, M., Mariotti, G.V., 2006. FE Calculation Methodology for the Thermodynamic Fatigue Analysis of an Engine Component. ASME 8th Biennial Conference on Engineering Systems Design and Analysis Torino, Italy.

Asayama, T., Takasho, H., Kato, T., 2009. Probabilistic prediction of crack depth distributions observed in structures subjected to thermal fatigue. Journal of Pressure Vessel Technology, 131(1):011402. [doi:10.1115/1.3027457]

Bao, S., Jin, W., Guralnick, S.A., Erber, T., 2010. Two-parameter characterization of low cycle, hysteretic fatigue data. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 11(6):449–454. [doi:10.1631/jzus.A0900763]

Chamani, H., Shahangian, S.N., Jazayeri, S.A., 2007. Thermo-Mechanical Fatigue Life Prediction of a Heavy Duty Diesel Engine Liner. ASME Internal Combustion Engine Division Fall Technical Conference, Charleston, South Carolina, USA.

Damiani, T.M., Holliday, J.E., Zechmeister, M.J., Reinheimer, R.D., Jones, D.P., 2007. Thermal Fatigue Testing and Analysis of a Thick Perforated Ring. ASME Pressure Vessels and Piping Conference, San Antonio, Texas, USA.

Goswami, T., 1997. Low cycle fatigue life prediction-a new model. International Journal of Fatigue, 19(2):109–115. [doi:10.1016/S0142-1123(96)00065-5]

Jones, D.P., Holliday, J.E., Leax, T.R., Gordon, J.L., 2004. Analysis of a Thermal Fatigue Test of a Stepped Pipe. ASME/JSME Pressure Vessels and Piping Conference, San Diego, California, USA.

Kaisaki, N., Takasho, H., Kobayashi, S., 2008. Spectra Thermal Fatigue Tests under Frequency Controlled Fluid Temperature Variation: Superposed Sinusoidal Temperature Fluctuation Tests. ASME Pressure Vessels and Piping Conference, Chicago, Illinois, USA.

Lin, Z.M., 2006. Manufacture status and develop direction of engines. Journal of Aeroengine, 32(1):1–8.

Manson, S.S., 1966. Thermal Stress and Low Cycle Fatigue. McGraw-Hill, New York.

Malesys, N., Vincent, L., Hild, F., 2008. Probabilistic Modeling of Crack Networks in Thermal Fatigue. ASME Pressure Vessels and Piping Conference, Chicago, Illinois, USA.

Mönig, R., Keller, R.R., Volkert, C.A., 2004. Thermal fatigue testing of thin metal films. Review of Scientific Instruments, 75(11):4997–5004. [doi:10.1063/1.1809260]

Morita, A., Kagawa, H., Kubo, S., 2004. Evaluation of Multiple Crack Propagation Behavior in a Gas Turbine Blade Under Thermal Fatigue Condition. ASME/JSME Pressure Vessels and Piping Conference, San Diego, California, USA.

Musi, S., Beaud, F., 2003. An Analytical Model for Thermal Fatigue Crack Initiation and Propagation in Mixing Zones of Piping Systems. ASME Pressure Vessels and Piping Conference, Cleveland, Ohio, USA.

Piehler, R.S., Damiani, T.M., 2008. Fatigue and Crack Growth Analysis of a Thick Instrumentation Ring Subjected to Thermal Fatigue Cycling. ASME Pressure Vessels and Piping Conference, Chicago, Illinois, USA.

Ping, X., Guo, Y.W., 1984. Thermal Stress and Thermal Fatigue. National defense industry Press, Beijing, China.

Sakhuja, A., Brevick, J.R., 2004. Prediction of thermal fatigue in tooling for die-casting copper via finite element analysis. AIP Conferences Proceedings, 712(1):1881–1886. [doi:10.1063/1.1766807]

Wong, T.E., Chu, C., 2006. Thermal Fatigue Life Prediction Model of CCGA Tin-Lead and Lead-Free Interconnects. ASME International Mechanical Engineering Congress and Exposition, Chicago, Illinois, USA.

Zhou, X., Yu, X.L., 2008. Fatigue crack growth rate test using a frequency sweep method. Journal of Zhejiang University-SCIENCE A, 9(3):346–350. [doi:10.1631/jzus.A0720009]

Author information

Authors and Affiliations

Corresponding author

Additional information

Project (No. 50806040) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Zheng, Xq., Du, T. & Zhang, Yj. Prediction of thermal fatigue life of a turbine nozzle guide vane. J. Zhejiang Univ. Sci. A 12, 214–222 (2011). https://doi.org/10.1631/jzus.A1000233

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1000233