Abstract

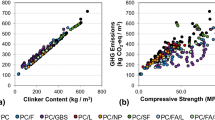

This study presents a novel framework for the design of reinforced concrete (RC) structures which aims at ensuring that future RC structures have the lowest possible carbon footprint, energy use and impact on the environment. The key focus of the study is on RC structures where there is often a lack of grasp of materials aspects, and environmental aspects of construction. In the proposed framework, a set of quantifiable design parameters and variables (binder type, concrete grade, diffusivity, concrete cover depth, area of steel in the structural component) are selected with respect to a set of performance measures which cover the functionality and availability of the structure to the user during its service life. The outputs generated from the framework are optimised material types and properties which not only meet the design performance requirements but also lead to minimised life-cycle environmental impacts. A RC beam is used to demonstrate the proposed design methodology. The application of the framework for design in the material specifications of the RC beam showed a reduced volume of materials in construction compared to the current materials and structures design practice.

Similar content being viewed by others

Notes

The cementing efficiency factor (k) is the mass of CEM I cement which gives a similar performance as a unit mass of the supplementary cementitious material (EN 206-1:2000).

References

Raju NK (1995) Prestressed concrete, 3rd edn. Tata McGraw-Hill, New Delhi

Collepardi M, Marcialis A, Turriziani R (1972) Penetration of chloride ions into cement pastes and concrete. J Am Concr Soc 55:534–535

CEMBUREAU, 2009 http://www.cembureau.be/about-cement/key-facts-figures. Accessed 8 Dec 2010

Muigai R, Alexander MG, Moyo P (2012) Cradle-to-gate environmental impacts of the concrete industry in South Africa. J South Afr Inst Civ Eng 55(2):2–7

Bentur A, Diamond S, Berke NS (1997) Steel corrosion in concrete: fundamentals and civil engineering practice. E & FN Spon, London

fib Model code for concrete structures, 2010. Ernst & Sohn, p 402

Ang AHS, Cornell CA (1974) Reliability bases of structural safety and design. J Struct Div 100:1755–1769

Faber MH, Sørensen JD (2002) Reliability based code calibration joint committee on structural safety. Paper for the Joint Committee on Structural Safety Draft

Gehlen C, Schiessl P (1999) Probability-based durability design for the Western-Scheldt tunnel. Concr J fib P 1(2):1–7

ISO 2394 (1998) General principles on reliability for structures. ISO, London

EN 1990-1 (2002) Basis of structural design, European Committee for Standardization (CEN)

ISO 13823 (2008) General principles on the design of structures for durability. ISO, London

Muigai R, Moyo P, Alexander M (2012) Durability design of reinforced concrete structures: a comparison of the use of durability indexes in the deemed-to-satisfy approach and the full-probabilistic approach. Mater Struct. doi:10.1617/s11527-012-9829-y

Lepech MD, Geiker M, Stang H (2011) Probabilistic design framework for sustainable repair and rehabilitation of civil infrastructure. fib Symposium Prague, pp 1029–1032

Kyoto Protocol (1998) Kyoto protocol to the United Nations Framework Convention on Climate Change. http://unfccc.int/resource/docs/convkp/kpeng.pdf. Accessed 06 Feb 2013

EN 1991 Eurocode 1: Actions on structures

EN 206–1 (2013) Concrete-Part 1: specification, performance, production and conformity. British Standards Institution, London, p 70

IPCC Fourth Assessment Report (2007). Climate Change: working group I: the physical science basis 2007 . http://www.ipcc.ch/publications_and_data/ar4/wg1/en/annex1sglossary-e-o.html

Gilchrist A, Allouche EN (2005) Quantification of social costs associated with construction projects: state-of-the-art review. Tunn Undergr Space Technol 20(1):89–104

Papadakis VG, Roumeliotis AP, Fardis MN, Vagenas CG (1996) Mathematical modelling of chloride effect on concrete durability and protection measures. In: Dhir RK, Jones MR (eds) Concrete reoair, rehabilitation and protection. E&FN Spon, London, pp 165–174

Papadakis VG, Tsimas S (2002) Supplementary cementing materials in concrete. Part I: efficiency and design. Cem Concr Res 32(2002):1525–1532

European Federation of Concrete Admixture Associations (2006) EFCA Environmental declaration superplasticizing admixtures. EFCA doc. 325 LTG

SimaPro Version 7.1 (2008) LCA Calculation software, PRé Consultants. The Netherlands

Muigai R (2014) A framework towards the design of more sustainable concrete structures. PhD Thesis, University of Cape Town

EN 1992-1-1 (2004) Design of concrete structures––Part 1-1: general rules and rules for buildings. European Committee for Standardization (CEN)

Drud AS (1994) CONOPT––a large scale GRG code. ORSA J Comput 6(2):207–216

BS 8500-1 (2006) Concrete. Complementary British Standard to BS EN 206-1. Method of specifying and guidance for the specifier. BSI, London

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

1.1 Bending moment constraint

M Rd is evaluated using simplified design formulations based on the rectangular stress-block. The maximum M Ed due to g k and q k occurs at mid-span of the beam and is given as:

where, γ g (−) is the partial load factor for the dead load and is given as γ g = 1.35, in EN 1992-1-1:2004 [14], γ q (−) is the partial load factor for the live load and is given as γ q = 1.5, in EN 1992-1-1:2004 [14], l (m) is the effective span of the beam.

‘q k ’ is assumed to be 30 kN/m whereas the dead load, ‘g k ’, is a variable represented as:

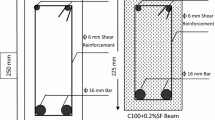

where, ρ c (kg/m3) is the density of concrete; ρ s (kg/m3) is the density of steel; and the other variables are as defined in Fig. 3.

In summary, C1 is a non-linear limit-state function represented by Eq. (18).

where, f cm (MPa) is the design mean strength of concrete and is equal to (f ck + 8) MPa; f ym (MPa) is the mean strength of steel and is taken as f yk; d (mm) is the effective depth of the beam; and the other variables are as defined in Fig. 3 and Eq. (18).

1.2 Maximum and minimum bending reinforcement

where, the design parameters, b, d, x min and Ø are as shown in Fig. 3.

A s,min minimizes thermal and shrinkage cracking whereas A s,max allows for adequate placing and compaction of concrete around the reinforcement.

1.3 Global warming potential

The global warming potential (GWP) is defined as an index, based upon radiative properties of well-mixed greenhouse gases, measuring the radiative forcing of a unit mass of a given well-mixed greenhouse gas in the present-day atmosphere integrated over a chosen time horizon, relative to that of carbon dioxide. The GWP represents the combined effect of the differing times these gases remain in the atmosphere and their relative effectiveness in absorbing outgoing thermal infrared radiation (IPCC 4th Assessment Report, 2007).

1.4 Design variables

1.4.1 Chloride diffusion coefficient

The chloride diffusion coefficient (D o) (m2/s) is related to mix design proportions as follows Papadakis et al. [20]

where, w (kg) is the water content, c (kg) is the cement content, a (kg) is the aggregate content, ρ c (kg/m3) is the density of cement, ρ a (kg/m3) is the density of aggregates, \(D{}_{{{\text{H}}_{ 2} {\text{O}}}}\) is the (m2/s) diffusion coefficient in an ionic solution of 0.5 M NaCl and is equal to 1.6 × 10−9 m2/s (50,458 mm2/year).

Equation (20) was selected for this study to predict the chloride diffusion coefficient in concrete as it accounts for the concrete mix proportions (aggregate-to-cement ratio; water-to-cement ratio and mass densities of cement and aggregates).

1.4.2 Concrete compressive strength

The study applies Eq. (21) to predict the strength of concrete for all the different cement types Papadakis and Tsimas [21].

where, K B is the Bolomey coefficient that depends on the aggregate type and concrete strength (MPa), and is assumed to be 21.3 MPa for all concrete types; w is the water content (kg/m3); c is the cement content (kg/m3); P is the content of the supplementary cementitious material (SCM) in concrete (kg/m3); and a depends on the time and curing of the concrete and is estimated as 0.5 for f ck at 28 days Papadakis and Tsimas [21]; k is the cementing efficiency coefficientFootnote 1 of the respective SCM.

Rights and permissions

About this article

Cite this article

Muigai, R., Alexander, M. & Moyo, P. A novel framework towards the design of more sustainable concrete infrastructure. Mater Struct 49, 1127–1141 (2016). https://doi.org/10.1617/s11527-015-0563-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0563-0