Abstract

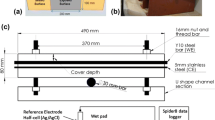

Most research on chloride-induced corrosion of reinforcing steel is conducted either in simulated pore solution or concrete. The former has the disadvantage that the experiments cannot replicate the environmental variations on the surface of the steel induced by the presence of the cementitious cover. The difficulty with the latter is that it is impossible to clearly assess the impact of many different parameters that influence the corrosion in commercial concrete. Consequently, the present study involves steel plates embedded in cement paste to minimize the number of active corrosion sites relative to steel in pore solution, thus simplifying an investigation into the location and accumulation of corrosion products in the cement paste and the influence of cracks on the corrosion process.

Corrosion monitoring techniques (i.e., open circuit potential mapping, linear polarization resistance) were correlated with chemical and microstructural analyses, including Raman spectroscopy of the corrosion products, to study the specimens. The results indicate the following: a range of corrosion products forms, primarily within shrinkage cracks; their specific volumes are typically in the range of 2 to 3; cracks had a greater impact on the corrosion rate of steel in white cement than in Type 10 cement; and that the surface sealing of the cracks using epoxy did not prevent corrosion initiation from occurring under the epoxy.

Résumé

La plupart des travaux de recherche sur la corrosion provoquée par les chlorures, attaquant l’armature d’acier sont menés soit en solution interstitielle synthétique ou dans le béton. Le problème de l’utilisation de la solution interstitielle vient du fait que les expériences ne peuvent pas reproduire les inhomogénéités présentes à la surface de l’acier, causées par le couvert de béton. Pour le béton, il est impossible d’obtenir une évaluation claire de l’impact des differents paramètres qui influencent la corrosion du béton commercial. C’est pourquoi notre étude utilise des plaques d’acier intégrées dans une pâte de ciment afin de minimiser le nombre de sites actifs de corrosion, liés à l’acier en solution interstitielle. Par conséquent, le travail de recherche des points de formation des produits de la corrosion dans la pâte de ciment est simplifié, ainsi que pour l’étude de l’influence des fissures sur le procédé de la corrosion.

Les techniques de contrôle de la corrosion (i.e. la mesure du potentiel en circuit ouvert et la résistance de la polarisation linéaire) sont corrélées avec des analyses chimiques et de microstructure : parmi elles, la spectroscopie Raman, afin d’étudier les spécimens. Les résultats suivants sont obtenus : diverses produits de corrosion se forment, surtout à l’intérieur des fissures de rétrécissement, les volumes spécifiques sont dans un intervalle typique de 2 à 3, les fissures ont un impact plus important sur le taux de corrosion de l’acier dans un ciment blanc que dans un ciment de type 10 et le joint à la surface des fissures utilisant de l’époxy n’empêche pas la formation de la corrosion sous l’époxy.

Similar content being viewed by others

References

Boddy A, Bentz EC, Thomas MDA, Hooton RD (1999) On overview and sensitivity study of a multimechanistic chloride transport model. Cem Concr Res 29(6):827–837

Liang MT, Wang KL, Liang CH (1999) Service life prediction of reinforced concrete structures. Cem Concr Res 29(9):1411–1418

Martín-Pérez B, Zibara H, Hooton RD, Thomas MDA (2000) A study of the effect of chloride binding on service life predictions. Cem Concr Res 30(8):1215–1223

Kirkpatrick TJ, Weyers RE, Anderson-Cook CM, Sprinkel MM (2002) Probabilistic model for the chloride-induced corrosion service life of bridge decks. Cem Concr Res 32(12):1943–1960

Thomas MDA, Bentz EC (2000) Life-365 computer program for predicting the service life and life-cycle costs of reinforced concrete exposed to chlorides, University of Toronto

Materials Service Life LLC, Kalamazoo, MI

Marcotte TD (2001) Characterization of chloride-induced corrosion products that form in steel-reinforced cementitious materials. PhD thesis. University of Waterloo, Canada

Mammoliti LT, Brown LC et al (1996) The influence of surface finish of reinforcing steel and pH of the test solution on the chloride threshold concentration for corrosion initiation in synthetic pore solutions. Cem Concr Res 26(4):545–550

Alonso C, Andrade C et al (2000) Chloride threshold values to depassivate reinforcing bars embedded in a standardized OPC mortar. Cem Concr Res 30:1047–1055

Li L, Sagüés AA (2001) Chloride corrosion threshold of reinforcing steel in alkaline solutions–open-circuit immersion tests. Corrosion 57(1):19–28

Génin J-MR, Rezel D et al (1986) Mössbauer spectroscopy characterization and electrochemical study of the kinetics of oxidation of iron in chlorinated aqueous media: structure and equilibrium diagram of green rust one. Mater Sci Forum, Electrochem Methods Corr Res 8:477–490

Refait P, Génin J-MR (1993) The oxidation of ferrous hydroxide in chloride-containing aqueous media and Pourbaix diagrams of green rust one. Corros Sci 34(5):797–819

Génin JMR, Refait P et al (1997) Green rusts, intermediate corrosion products formed on rebars in concrete in the presence of carbonation or chloride ingress’ In: ‘Understanding corrosion mechanisms in concrete: a key to improving infrastructure durability’ Proceedings of an International Symposium, Massachusetts Institute of Technology, Cambridge, 1997 (Extended abstract)

Marcotte TD, Hansson CM (2003) The influence of silica fume on the corrosion resistance of steel in high performance concrete exposed to simulated sea water. J Mater Sci 38:4765–4776

Andrade C, Alonso C (1993) Cover cracking as a function of bar corrosion Part I-Experimental test. Mater Struct 26:453–464

Molina FJ, Alonso C et al (1993) Cover cracking as a function of rebar corrosion Part 2-Numerical model. Mater Struct 26:5a32–548

Aligizaki KK, de Rooij MR et al (2000) Analysis of iron oxides accumulating at the interface between aggregates and cement paste. Cem Concr Res 30:1941–1945

Lide DR (ed) (1999) CRC handbook of chemistry and physics, 80th edn, CRC Press, New York

Trolard F, Génin J-MR et al (1997) Identification of a green rust mineral in a reductomorphic soil by Mössbauer and Raman spectroscopies. Geochim Cosmochim Ac 61(5):1107–1111

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marcotte, T., Hansson, C. Corrosion products that form on steel within cement paste. Mater Struct 40, 325–340 (2007). https://doi.org/10.1617/s11527-006-9170-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-006-9170-4