Abstract

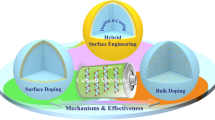

The use of in situ formed protective layer on conversion cathodes was introduced as a cheap and simple strategy to shield these materials from undesirable interactions with liquid electrolytes.

Conversion-type cathodes have been viewed as promising candidates to replace Ni- and Co-based intercalation-type cathodes for next-generation lithium (Li) and Li-ion batteries with higher specific energy, lower cost, and potentially longer cycle life. Typically, in conversion reactions two or three Li ions may be stored per just one atom of chalcogen (e.g., S or Se) or transition metal (e.g., Fe or Cu used in halides). Unfortunately, in conversion chemistries the active materials or intermediate charge/discharge products suffer from various unfavorable interactions and dissolution in organic electrolytes. In this mini-review article, we discuss the current interfacial challenges and focus on the protective layers in situ formed on the cathode surface to effectively shield conversion materials from undesirable interactions with liquid electrolytes. We further explore the mechanisms and current progress of forming such protective layers by using various salts, solvents, and additives together with the insight from molecular modeling. Finally, we discuss future opportunities and perspectives of in situ surface protection.

Similar content being viewed by others

References

Amarakoon S., Smith J., and Segal B.: Application of Life-Cycle Assessment to Nanoscale Technology: Lithium-ion Batteries for Electric Vehicles (US Environmental Protection Agency). Available at: https://www.epa.gov/sites/production/files/2014-01/documents/ lithium_batteries_lca.pdf (accessed April 24, 2013).

Suresh Gandhi M. and Raja M.: Heavy mineral distribution and geochemical studies of coastal sediments between Besant Nagar and Marakkanam, Tamil Nadu, India. J. Radiat. Res. Appl. Sci. 7, 256 (2014).

Frankel T.C., Chavez M.R., and Ribas J.: The cobalt pipeline: Tracing the path from deadly hand-dug mines in Congo to consumer s’ phones and laptops. The Washington Post (2016). Available at: https://www.washingtonpost.com/graphics/business/batteries/ congo-cobalt-mining-for-lithium-ion-battery/ (accessed 30 September 2016).

Liwanga R-C.: Child miners face death for tech. CNN (2013). Available at: http://thecnnfreedomproject.blogs.cnn.com/2013/06/26/ child-miners-face-death-for-tech/ (accessed 26 June 2013).

Zeng X., Xu X., Boezen H.M., and Huo X.: Children with health impairments by heavy metals in an e-waste recycling area. Chemosphere 148, 408 (2016).

Wu F. and Yushin G.: Conversion cathodes for rechargeable lithium and lithium-ion batteries. Energy Environ. Sci. 10, 435 (2017).

Nitta N., Wu F., Lee J.T., and Yushin G.: Li-ion battery materials: Present and future. Mater. Today 18, 252 (2015).

Choi J.W. and Aurbach D.: Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 1, 16013 (2016).

Badway F., Pereira N., Cosandey F., and Amatucci G.G.: Carbon-metal fluoride nanocomposites. J. Electrochem. Soc. 150, A1209 (2003).

Wang F., Robert R., Chernova N.A., Pereira N., Omenya F., Badway F., Hua X., Ruotolo M., Zhang R., Wu L., Volkov V., Su D., Key B., Whittingham M.S., Grey C.P., Amatucci G.G., Zhu Y., and Graetz J.: Conversion reaction mechanisms in lithium ion batteries: Study of the binary metal fluoride electrodes. J. Am. Chem. Soc. 133, 18828 (2011).

Liu Y., Wang J., Xu Y., Zhu Y., Bigio D., and Wang C.: Lithium-tellurium batteries based on tellurium/porous carbon composite. J. Mater. Chem. A 2, 12201 (2014).

Yang Y., Zheng G., Misra S., Nelson J., Toney M.F., and Cui Y.: High-capacity micrometer-sized Li2S particles as cathode materials for advanced rechargeable lithium-ion batteries. J. Am. Chem. Soc. 134, 15387 (2012).

Li Z., Yuan L., Yi Z., Liu Y., and Huang Y.: Confined selenium within porous carbon nanospheres as cathode for advanced Li-Se batteries. Nano Energy 9, 229 (2014).

Lin Z., Liu Z., Dudney N.J., and Liang C.: Lithium superionic sulfide cathode for all-solid lithium-sulfur batteries. ACS Nano 7, 2829 (2013).

Badway F., Cosandey F., Pereira N., and Amatucci G.G.: Carbon metal fluoride nanocomposites. J. Electrochem. Soc. 150, A1318 (2003).

Hua X., Robert R., Du L-S., Wiaderek K.M., Leskes M., Chapman K.W., Chupas P.J., and Grey C.P.: Comprehensive study of the CuF2 conversion reaction mechanism in a lithium ion battery. J. Mater. Chem. C 118, 15169 (2014).

Wang X., Gu W., Lee J.T., Nitta N., Benson J., Magasinski A., Schauer M.W., and Yushin G.: Carbon nanotube-CoF2 multifunctional cathode for lithium ion batteries: Effect of electrolyte on cycle stability. Small 11, 5164 (2015).

Cui Y., Abouimrane A., Lu J., Bolin T., Ren Y., Weng W., Sun C., Maroni V.A., Heald S.M., and Amine K.: (De)lithiation mechanism of Li/SeS(x) (x = 0-7) batteries determined by in situ synchrotron X-ray diffraction and X-ray absorption spectroscopy. J. Am. Chem. Soc. 135, 8047 (2013).

Son Y., Lee J-S., Son Y., Jang J-H., and Cho J.: Recent advances in lithium sulfide cathode materials and their use in lithium sulfur batteries. Adv. Energy Mater. 5, 201500110 (2015).

Manthiram A., Fu Y., Chung S.H., Zu C., and Su Y.S.: Rechargeable lithium-sulfur batteries. Chem. Rev. 114, 11751 (2014).

Lee J.T., Zhao Y., Thieme S., Kim H., Oschatz M., Borchardt L., Magasinski A., Cho W-I., Kaskel S., and Yushin G.: Sulfur-infiltrated micro- and mesoporous silicon carbide-derived carbon cathode for high-performance lithium sulfur batteries. Adv. Mater. 25, 4573 (2013).

Kim H., Lee J.T., and Yushin G.: High temperature stabilization of lithium- sulfur cells with carbon nanotube current collector. J. Power Sources 226, 256 (2013).

Lee J.T., Kim H., Oschatz M., Lee D-C., Wu F., Lin H-T., Zdyrko B., Cho W.I., Kaskel S., and Yushin G.: Micro- and mesoporous carbidederived carbon-selenium cathodes for high-performance lithium selenium batteries. Adv. Energy Mater. 5, 201400981 (2015).

Zhang S., Ueno K., Dokko K., and Watanabe M.: Recent advances in electrolytes for lithium-sulfur batteries. Adv. Energy Mater. 5, 201400981 (2015).

Yang C-P., Yin Y-X., and Guo Y-G.: Elemental selenium for electrochemical energy storage. J. Phys. Chem. Lett. 6, 256 (2015).

Ding N., Chen S-F., Geng D-S., Chien S-W., An T., Hor T.S.A., Liu Z-L., Yu S-H., and Zong Y.: Tellurium@ordered macroporous carbon composite and free-standing tellurium nanowire mat as cathode materials for rechargeable lithium-tellurium batteries. Adv. Energy Mater. 5, 201401999 (2015).

Zhou J., Zhang D., Zhang X., Song H., and Chen X.: Carbon-nanotubeencapsulated FeF2 nanorods for high-performance lithium-ion cathode materials. ACS Appl. Mater. Interfaces 6, 21223 (2014).

Wu F., Lee J.T., Fan F., Nitta N., Kim H., Zhu T., and Yushin G.: A hierarchical particle-shell architecture for long-term cycle stability of Li2S cathodes. Adv. Mater. 27, 5579 (2015).

Fan X., Luo C., Lamb J., Zhu Y., Xu K., and Wang C.: PEDOT encapsulated FeOF nanorod cathodes for high energy lithium-ion batteries. Nano Lett. 15, 7650 (2015).

Jiang J., Zhu J., Ai W., Wang X., Wang Y., Zou C., Huang W., and Yu T.: Encapsulation of sulfur with thin-layered nickel-based hydroxides for long-cyclic lithium-sulfur cells. Nat. Commun. 6, 8622 (2015).

Wu F., Lee J.T., Zhao E., Zhang B., and Yushin G.: Graphene-Li2S-carbon nanocomposite for lithium-sulfur batteries. ACS Nano 10, 1333 (2016).

Nan C., Lin Z., Liao H., Song M-K., Li Y., and Cairns E.J.: Durable carboncoated Li2S core-shell spheres for high performance lithium/sulfur cells. J. Am. Chem. Soc. 136, 4659 (2014).

Peruzzi N., Ninham B.W., Lo Nostro P., and Baglioni P.: Hofmeister phenomena in nonaqueous media: The solubility of electrolytes in ethylene carbonate. J. Phys. Chem. B 116, 14398 (2012).

Hu H., Cheng H., Liu Z., Li G., Zhu Q., and Yu Y.: In situ polymerized PAN-assisted S/C nanosphere with enhanced high-power performance as cathode for lithium/sulfur batteries. Nano Lett. 15, 5116 (2015).

Seh Z.W., Li W., Cha J.J., Zheng G., Yang Y., McDowell M.T., Hsu P-C., and Cui Y.: Sulphur-TiO2 yolk-shell nanoarchitecture with internal void space for long-cycle lithium-sulphur batteries. Nat. Commun. 4, 1331 (2013).

Zhou W., Yu Y., Chen H., DiSalvo F.J., and Abruña H.D.: Yolk-shell structure of polyaniline-coated sulfur for lithium-sulfur batteries. J. Am. Chem. Soc. 135, 16736 (2013).

Oschatz M., Lee J.T., Kim H., Nickel W., Borchardt L., Cho W.I., Ziegler C., Kaskel S., and Yushin G.: Micro- and mesoporous carbide-derived carbon prepared by a sacrificial template method in high performance lithium sulfur battery cathodes. J. Mater. Chem. A 2, 17649 (2014).

Liang X., Hart C., Pang Q., Garsuch A., Weiss T., and Nazar L.F.: A highly efficient polysulfide mediator for lithium-sulfur batteries. Nat. Commun. 6, 5682 (2015).

Wu F., Lee J.T., Nitta N., Kim H., Borodin O., and Yushin G.: Lithium iodide as a promising electrolyte additive for lithium-sulfur batteries: Mechanisms of performance enhancement. Adv. Mater. 27, 101 (2015).

Wu F., Lee J.T., Magasinski A., Kim H., and Yushin G.: Solution-based processing of graphene-Li2S composite cathodes for lithium-ion and lithium-sulfur batteries. Part. Part. Syst. Charact. 31, 639 (2014).

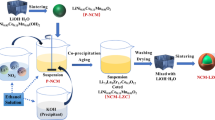

Wu F., Kim H., Magasinski A., Lee J.T., Lin H-T., and Yushin G.: Harnessing steric separation of freshly nucleated Li2S nanoparticles for bottom-up assembly of high-performance cathodes for lithium-sulfur and lithium-ion batteries. Adv. Energy Mater. 4, 201400196 (2014).

Wu F., Zhao E., Gordon D., Xiao Y., Hu C., and Yushin G.: Infiltrated porous polymer sheets as free-standing flexible lithium-sulfur battery electrodes. Adv. Mater. 28, 6365 (2016).

Wu F., Lee J.T., Xiao Y., and Yushin G.: Nanostructured Li2Se cathodes for high performance lithium-selenium batteries. Nano Energy 27, 238 (2016).

Wu F., Magasinski A., and Yushin G.: Nanoporous Li2S and MWCNTlinked Li2S powder cathodes for lithium-sulfur and lithium-ion battery chemistries. J. Mater. Chem. A 2, 6064 (2014).

Lee J.T., Eom K., Wu F., Kim H., Lee D.C., Zdyrko B., and Yushin G.: Enhancing the stability of sulfur cathodes in Li-S cells via in situ formation of a solid electrolyte layer. ACS Energy Lett. 1, 373 (2016).

Gu W., Borodin O., Zdyrko B., Lin H-T., Kim H., Nitta N., Huang J., Magasinski A., Milicev Z., Berdichevsky G., and Yushin G.: Lithium-iron fluoride battery with in situ surface protection. Adv. Funct. Mater. 26, 1507 (2016).

Gu W., Magasinski A., Zdyrko B., and Yushin G.: Metal f luorides nanoconfined in carbon nanopores as reversible high capacity cathodes for Li and Li-ion rechargeable batteries: FeF2 as an example. Adv. Energy Mater. 5, 201401148 (2015).

Li T., Chen Z.X., Cao Y.L., Ai X.P., and Yang H.X.: Transition-metal chlorides as conversion cathode materials for Li-ion batteries. Electrochim. Acta 68, 202 (2012).

Gmitter A.J., Badway F., Rangan S., Bartynski R.A., Halajko A., Pereira N., and Amatucci G.G.: Formation, dynamics, and implication of solid electrolyte interphase in high voltage reversible conversion fluoride nanocomposites. J. Mater. Chem. 20, 4149 (2010).

Wang F., Kim S-W., Seo D-H., Kang K., Wang L., Su D., Vajo J.J., Wang J., and Graetz J.: Ternary metal fluorides as high-energy cathodes with low cycling hysteresis. Nat. Commun. 6, 6668 (2015).

Shi Y-L., Shen M-F., Xu S-D., Zhuang Q-C., Jiang L., and Qiang Y-H.: Electrochemical impedance spectroscopy investigation of the FeF3/C cathode for lithium-ion batteries. Solid State Ionics 222-223, 23 (2012).

Zheng S., Han P., Han Z., Zhang H., Tang Z., and Yang J.: High performance C/S composite cathodes with conventional carbonatebased electrolytes in Li-S battery. Sci. Rep. 4, 4842 (2014).

Gao J., Lowe M.A., Kiya Y., and Abruña H.D.: Effects of liquid electrolytes on the charge-discharge performance of rechargeable lithium/sulfur batteries: Electrochemical and in situ X-ray absorption spectroscopic studies. J. Mater. Chem. C 115, 25132 (2011).

Yim T., Park M-S., Yu J-S., Kim K.J., Im K.Y., Kim J-H., Jeong G., Jo Y.N., Woo S-G., Kang K.S., Lee I., and Kim Y-J.: Effect of chemical reactivity of polysulfide toward carbonate-based electrolyte on the electrochemical performance of Li-S batteries. Electrochim. Acta 107, 454 (2013).

Kim H., Wu F., Lee J.T., Nitta N., Lin H-T., Oschatz M., Cho W.I., Kaskel S., Borodin O., and Yushin G.: In situ formation of protective coatings on sulfur cathodes in lithium batteries with LiFSI-based organic electrolytes. Adv. Energy Mater. 5, 201401792 (2015).

Barghamadi M., Best A.S., Bhatt A.I., Hollenkamp A.F., Mahon P.J., Musameh M., and Rüther T.: Effect of LiNO3 additive and pyrrolidinium ionic liquid on the solid electrolyte interphase in the lithium-sulfur battery. J. Power Sources 295, 212 (2015).

Lin Z., Liu Z., Fu W., Dudney N.J., and Liang C.: Phosphorous pentasulfide as a novel additive for high-performance lithium-sulfur batteries. Adv. Funct. Mater. 23, 1064 (2013).

Xiong S., Xie K., Diao Y., and Hong X.: Properties of surface film on lithium anode with LiNO3 as lithium salt in electrolyte solution for lithium-sulfur batteries. Electrochim. Acta 83, 78 (2012).

Barghamadi M., Best A.S., Bhatt A.I., Hollenkamp A.F., Musameh M., Rees R.J., and Ruther T.: Lithium-sulfur batteries-the solution is in the electrolyte, but is the electrolyte a solution? Energy Environ. Sci. 7, 3902 (2014).

Wang Y.L., Sun Q.L., Zhao Q.Q., Cao J.S., and Ye S.H.: Rechargeable lithium/iodine battery with superior high-rate capability by using iodine- carbon composite as cathode. Energy Environ. Sci. 4, 3947 (2011).

Li B., Li S., Liu J., Wang B., and Yang S.: Vertically aligned sulfur-graphene nanowalls on substrates for ultrafast lithium-sulfur batteries. Nano Lett. 15, 3073 (2015).

Tan J., Liu L., Guo S., Hu H., Yan Z., Zhou Q., Huang Z., Shu H., Yang X., and Wang X.: The electrochemical performance and mechanism of cobalt(II) fluoride as anode material for lithium and sodium ion batteries. Electrochim. Acta 168, 225 (2015).

Cui Y-H., Xue M-Z., Zhou Y-N., Peng S-M., Wang X-L., and Fu Z-W.: The investigation on electrochemical reaction mechanism of CuF2 thin film with lithium. Electrochim. Acta 56, 2328 (2011).

Hu B., Wang X., Wang Y., Wei Q., Song Y., Shu H., and Yang X.: Effects of amorphous AlPO4 coating on the electrochemical performance of BiF3 cathode materials for lithium-ion batteries. J. Power Sources 218, 204 (2012).

Ma R., Lu Z., Wang C., Wang H.E., Yang S., Xi L., and Chung J.C.: Large-scale fabrication of graphene-wrapped FeF3 nanocrystals as cathode materials for lithium ion batteries. Nanoscale 5, 6338 (2013).

Zhou H., Ruther R.E., Adcock J., Zhou W., Dai S., and Nanda J.: Controlled formation of mixed nanoscale domains of high capacity Fe2O3–FeF3 conversion compounds by direct fluorination. ACS Nano 9, 2530 (2015).

Hu X., Ma M., Mendes R.G., Zeng M., Zhang Q., Xue Y., Zhang T., Rummeli M.H., and Fu L.: Li-storage performance of binder-free and flexible iron f luoride@graphene cathodes. J. Mater. Chem. A 3, 23930 (2015).

Fan X., Zhu Y., Luo C., Gao T., Suo L., Liou S-C., Xu K., and W ang C.: In situ lithiated FeF3/C nanocomposite as high energy conversion-reaction cathode for lithium-ion batteries. J. Power Sources 307, 435 (2016).

Teng Y.T., Wei F., and Yazami R.: Synthesis of Nix Co(1−x)F2 (x =0,0.2., 0.50, 0.75, 1.0) and application in lithium ion batteries. J. Alloys Compd. 653, 434 (2015).

Lee D.H., Carroll K.J., Calvin S., Jin S., and Meng Y.S.: Conversion mechanism of nickel f luoride and NiO-doped nickel f luoride in Li ion batteries. Electrochim. Acta 59, 213 (2012).

Wang L., Guo C., Zhu Y., Zhou J., Fan L., and Qian Y.: A FeCl(2)–graphite sandwich composite with Cl doping in graphite layers: A new anode material for high-performance Li-ion batteries. Nanoscale 6, 14174 (2014).

Liu J-l., Cui W-j., Wang C-x., and Xia Y-y.: Electrochemical reaction of lithium with CoCl2 in nonaqueous electrolyte. Electrochem. Commun. 13, 269 (2011).

Liang X., Garsuch A., and Nazar L.F.: Sulfur cathodes based on conductive MXene nanosheets for high-performance lithium–sulfur batteries. Angew. Chem. Int. Ed. 54, 3907 (2015).

Qu Q., Gao T., Zheng H., Wang Y., Li X., Li X., Chen J., Han Y., Shao J., and Zheng H.: Strong surface-bound sulfur in conductive MoO2 matrix for enhancing Li–S battery performance. Adv. Mater. Interfaces 2, 201500048 (2015).

Zeng L., Zeng W., Jiang Y., Wei X., Li W., Yang C., Zhu Y., and Yu Y.: A flexible porous carbon nanofibers–selenium cathode with superior electrochemical performance for both Li–Se and Na–Se batteries. Adv. Energy Mater. 5, 201401377 (2015).

Han K., Liu Z., Shen J., Lin Y., Dai F., and Ye H.: A free-standing and ultralong-life lithium–selenium battery cathode enabled by 3D mesoporous carbon/graphene hierarchical architecture. Adv. Funct. Mater. 25, 455 (2015).

Zhang J., Yin Y-X., You Y., Yan Y., and Guo Y-G.: A high-capacity tellurium@carbon anode material for lithium-ion batteries. Energy Technol. 2, 757 (2014).

Zhao Q., Lu Y., Zhu Z., Tao Z., and Chen J.: Rechargeable lithium–iodine batteries with iodine/nanoporous carbon cathode. Nano Lett. 15, 5982 (2015).

Lin Y-X., Liu Z., Leung K., Chen L-Q., Lu P., and Qi Y.: Connecting the irreversible capacity loss in Li-ion batteries with the electronic insulating properties of solid electrolyte interphase (SEI) components. J. Power Sources 309, 221 (2016).

Leung K., Qi Y., Zavadil K.R., Jung Y.S., Dillon A.C., Cavanagh A.S., Lee S-H., and George S.M.: Using atomic layer deposition to hinder solvent decomposition in lithium ion batteries: First-principles modeling and experimental studies. J. Am. Chem. Soc. 133, 14741 (2011).

Single F., Horstmann B., and Latz A.: Dynamics and morphology of solid electrolyte interphase (SEI). Phys. Chem. Chem. Phys. 18, 17810 (2016).

Leung K., Soto F., Hankins K., Balbuena P.B., and Harrison K.L.: Stability of solid electrolyte interphase components on lithium metal and reactive anode material surfaces. J. Phys. Chem. C 120, 6302 (2016).

Zhu Y., He X., and Mo Y.: First principles study on electrochemical and chemical stability of solid electrolyte–electrode interfaces in all-solid-state Li-ion batteries. J. Mater. Chem. A 4, 3253 (2016).

Delp S.A., Borodin O., Olguin M., Eisner C.G., Allen J.L., and Jow T.R.: Importance of reduction and oxidation stability of high voltage electrolytes and additives. Electrochim. Acta 209, 498 (2016).

Borodin O., Olguin M., Spear C.E., Leiter K., and Knap J.: Towards high throughput screening of electrochemical stability of battery electrolytes. Nanotechnology 26, 354003 (2015).

Borodin O., Behl W., and Jow T.R.: Oxidative stability and initial decomposition reactions of carbonat, sulfon, and alkyl phosphate-based electrolytes. J. Phys. Chem. C 117, 8661 (2013).

Borodin O.: Molecular modeling of electrolytes. In Electrolytes for Lithium and Lithium-Ion Batteries, Jow T.R., Xu K., Borodin O., and Ue M., eds. (Springe., New York, 2014); p. 371.

Wu F., Borodin O., and Yushin G.: Toward in situ protected sulfur cathodes by using lithium bromide and pre-charge. Under revie., (2017).

Suo L., Borodin O., Sun W., Fan X., Yang C., Wang F., Gao T., Ma Z., Schroeder M., von Cresce A., Russell S.M., Armand M., Angell A., Xu K., and Wang C.: Advanced high-voltage aqueous lithium-ion battery enabled by “Water-in-Bisalt” electrolyte. Angew. Chem. Int. Ed. 55, 7136 (2016).

Vatamanu J., Borodin O., and Smith G.D.: Molecular dynamics simulation studies of the structure of a mixed carbonate/LiPF6 electrolyte near graphite surface as a function of electrode potential. J. Phys. Chem. C 116, 1114 (2012).

Borodin O., Olguin M., Spear C., Leiter K., Knap J., Yushin G., Childs A., and Xu K.: (Invited) challenges with quantum chemistry-based screening of electrochemical stability of lithium battery electrolytes. ECS Trans. 69, 113 (2015).

Meini S., Elazari R., Rosenman A., Garsuch A., and Aurbach D.: The use of redox mediators for enhancing utilization of Li2S cathodes for advanced Li–S battery systems. J. Phys. Chem. Lett. 5, 915 (2014).

Liu T., Leskes M., Yu W., Moore A.J., Zhou L., Bayley P.M., Kim G., and Grey C.P.: Cycling Li–O2 batteries via LiOH formation and decomposition. Science 350, 530 (2015).

Hu J.J., Long G.K., Liu S., Li G.R., and Gao X.P.: A LiFSI–LiTFSI binary-salt electrolyte to achieve high capacity and cycle stability for a Li–S battery. Chem. Commun. 50, 14647 (2014).

Gmitter A.J., Gural J., and Amatucci G.G.: Electrolyte development for improved cycling performance of bismuth fluoride nanocomposite positive electrodes. J. Power Sources 217, 21 (2012).

Lee J.T., Kim H., Nitta N., Eom K-s., Lee D-C., Wu F., Lin H-T., Zdyrko B., Cho W.I., and Yushin G.: Stabilization of selenium cathodes via in situ formation of protective solid electrolyte layer. J. Mater. Chem. A 2, 18898 (2014).

Song J-H., Yeon J-T., Jang J-Y., Han J-G., Lee S-M., and Choi N-S.: Effect of fluoroethylene carbonate on electrochemical performances of lithium electrodes and lithium–sulfur batteries. J. Electrochem. Soc. 160, A873 (2013).

Markevich E., Salitra G., Rosenman A., Talyosef Y., Chesneau F., and Aurbach D.: Fluoroethylene carbonate as an important component in organic carbonate electrolyte solutions for lithium sulfur batteries. Electrochem. Commun. 60, 42 (2015).

Jung R., Metzger M., Haering D., Solchenbach S., Marino C., Tsiouvaras N., Stinner C., and Gasteiger H.A.: Consumption of fluoroethylene carbonate (FEC) on Si–C composite electrodes for Li-ion batteries. J. Electrochem. Soc. 163, A1705 (2016).

Xu C., Lindgren F., Philippe B., Gorgoi M., Björefors F., Edström K., and Gustafsson T.: Improved performance of the silicon anode for Li-ion batteries: Understanding the surface modification mechanism of fluoroethylene carbonate as an effective electrolyte additive. Chem. Mater. 27, 2591 (2015).

Martinez de la Hoz J.M. and Balbuena P.B.: Reduction mechanisms of additives on Si anodes of Li-ion batteries. Phys. Chem. Chem. Phys. 16, 17091 (2014).

Acknowledgments

Different aspects of this work were supported by the Army Research Office (ARO Grant No. W911NF-17-1-0053), Air Force Office of Scientific Research (AFOSR Grant No. FA9550-13-1-0054) and NASA Minority University Research and Education Project (MUREP) project (NASA Grant Nos. NNX15AP44A and IAA NND16AA29I).

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Supplementary Material

To view supplementary material for this article, please visit https://doi.org/10.1557/mre.2017.11.

Rights and permissions

About this article

Cite this article

Wu, F., Borodin, O. & Yushin, G. In situ surface protection for enhancing stability and performance of conversion-type cathodes. MRS Energy & Sustainability 4, 9 (2017). https://doi.org/10.1557/mre.2017.11

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/mre.2017.11