Abstract

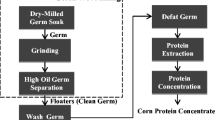

Increased demand for ethanol as a fuel additive has resulted in dramatic growth in ethanol production. Ethanol is produced from corn by either wet milling or dry-grind processing. In wet milling, the corn kernel is fractionated into different components, resulting in several coproducts. Wet-milling plants are capital intensive because of equipment requirements; they produce large volumes of ethanol and are corporate owned. In dry-grind processing, the corn kernel is not fractionated and only one coproduct, distillers’ dried grains with solubles (DDGS), is generated. Dry-grind plants require less equipment and capital than wet mills. They generate smaller volumes of ethanol, are producer owned, and add direct benefits to rural economies. Most of the increase in ethanol production during the past decade is attributed to growth in the dry-grind industry. The marketing of coproducts provides income to offset processing costs. For dry-grind plants, this is especially important, because only one coproduct is available. Several issues could affect DDGS marketing. The increasing volume of DDGS accompanying ethanol production could reduce market value; high phosphorous content could limit the use of DDGS, because of animal waste disposal issues. Water removal is a costly processing step and affects the economics of ethanol processing. Technologies to remove germ and fiber from DDGS could produce a new coproduct suitable for feeding to nonruminants; this would expand the markets for DDGS. Reducing phosphorus in DDGS would sustain markets for conventional DDGS. The development of more efficient methods of water removal would increase the efficiency of ethanol processing and reduce the costs of processing. New technologies could contribute to greater stability of dry-grind plants.

Similar content being viewed by others

References

RFA (2005), Renewable fuels outlook 2005, Renewable Fuels Association, Washington, DC, www.ethanolrfa.org.

ERS. (2005) Feed grains data delivery system, Economic Research Service, USDA, www.ers.usda.gov/db/feedgrains/.

Shapouri, H., Duffield, J. A., and Graboski, M. S. (1995), Estimating the Net Energy Balance of Corn Ethanol. AER-721. USDA Economic Research Service, Washington, DC.

Shapouri, H., Duffield, J. A., and Wang, M. (2002), The Energy Balance of Corn Ethanol: An Update. AER-814. USDA Office of the Chief Economist, Washington, DC.

Shapouri, H., Duffield, J. A., and Wang, M. (2003), Transactions of the ASAE 46(4), 959–968.

Rausch, K. D., Belyea, R. L., Singh, V., Johnston, D. B., Clevenger, T. E., and Tumbleson, M. E. 2003. in Proceedings of the International Starch Technology Conference, Urbana, IL, p. 134.

Rausch, K. D., Thompson, C. I., Belyea, R. L., and Tumbleson, M. E. (2003), Bioresour. Technol. 90, 49–54.

Loy, D. D. and Wright, K. N. (2003), in Corn: Chemistry and Technology, 2nd ed., (White, P. J. and Johnson, L. A., eds.), American Association of Cereal Chemistry, St. Paul, MN, pp. 571–603.

Duensing, W. J., Roskens, A. B., and Alexander, R. J. (2003), in Corn: Chemistry and Technology, 2nd ed., (White, P. J. and Johnson, L. A., eds.), American Association of Cereal Chemists, St. Paul, MN, pp. 407–448.

Alexander, R. J. (1987), in Corn: Chemistry and Technology, 1st ed., (Watson, S. A. and Ramstad, P. E., eds.), American Association of Cereal Chemists, St. Paul, MN, pp. 351–375.

Belyea, R. L., Wallig, M. A., Eckhoff, S. R., and Tumbleson, M. E. (1998), Bioresour. Technol. 66, 207–212.

Maisch, W. F. (2003), in Corn: Chemistry and Technology, 2nd ed., (White, P. J. and Johnson, L. A., eds.), American Association of Cereal Chemists, St. Paul, MN, pp. 695–721.

Christianson, D. D., Cavins, J. F., and Wall, J. S. (1965), J. Agric. Food Chem. 13, 378–380.

Rausch, K. D. (2002), Starch/Staerke 54, 273–284.

Johnson, L. A. and May, J. B. (2003), Corn: Chemistry and Technology, 2nd ed., (White, P. J. and Johnson, L. A., eds.). American Association of Cereal Chemists, St. Paul, MN, pp. 449–494.

Meredith, J. (2003), in The Alcohol Textbook 4th ed., (Jacques, K. A., Lyons, T. P., and Kelsall, D. R. eds.), Nottingham University Press, Nottingham, UK.

Singh, V., Johnston, D. B., Naidu, K., Rausch, K. D., Belyea, R. L., and Tumbleson, M. E. (2005), Cereal Chem. 82, 187–190.

Brekke, O. L. (1970), in Corn: Culture, Processing Products, (Inglett, G. E., ed.), AVI Publishing, Westport, CT, pp. 262–291.

NRC. (1980), Mineral tolerances of domestic animals, National Research Council, National Academy of Science, Washington, DC.

Wright, K. N. (1987), in Corn: Chemistry and Technology, 1st ed., (Watson, S. A. and Ramstad, P. E., eds.), American Association of Cereal Chemists, St. Paul, MN, p. 448.

Krishnamoorthy, U., Sniffen, C. J., and Van Soest, P. J. (1982), in Proceedings of the Cornell Nutritional Conference, Syracuse, NY, p. 95–102.

Morse, D., Head, H. H., Wilcox, C. J., Van Horn, H. H., Hissem, C. D., and Harris, Jr., B. (1992), J. Dairy Sci. 75, 3039–3049.

Dou, Z., Galligan, D. T., and Ramberg, Jr., C. F. (2001), J. Dairy Sci. 84, 966–973.

Rotz, C. A., Sharpley, A. N., Satter, L. D., Gburek, W. J., and Sanderson, M. A. (2002), J. Dairy Sci. 85, 3142–3153.

Spears, R. A., Young, A. J., and Kohn, R. A. (2003), J. Dairy Sci. 86, 688–695.

Tamminga, S. (1992), J. Dairy Sci. 75, 345–357.

Van Horn, H. H., Newton, G. L., and Kunkle, W. E. (1996), J. Anim. Sci. 74, 3082–3102.

Firkins, J. L. (2003), in Proceedings of the 3rd National Alternative Feeds Symposium, Kansas City, MO, p. 85–102.

Fellner, V. and Belyea, R. L. (1991), J. Dairy Sci. 74, 996–1005.

Van Soest, P. J. (1982), Nutritional Ecology of the Ruminant, Durham and Downey, Portland, OR.

Shurson, J., Spiehs, M., Whitney, M., et al. (2001), in 62nd Minnesota Nutritional Conference & Minnesota Corn Growers Association Technology Symposium, Bloomington, MN, p. 27–52.

Clevenger, T. E., Singh, V., Belyea, R. L., Johnston, D. B., Tumbleson, M. E. and Rausch, K. D. (2004), in Proceedings of the Corn Utilization Technology Conference, NCGA, St. Louis, MO.

Kung, L., Bracht, J. P., Hession, A. O., and Tavares, J. Y. (1998), Feedstuffs 72, 12–17.

Schingoethe, D. J., Clark, A. K., and Voelker, H. H. (1983), J. Dairy Sci. 66, 345–349.

Powers, W. J., Van Horn, H. H., Harris, B., and Wilcox, C. J. (1995), J. Dairy Sci. 78, 388–396.

Howard, W. T. and Shaver, R. D. (1997), FEEDVAL: Comparative values calculated from crude protein, TDN, Ca and P. Reference feeds used to calculate value of nutrients. www.wisc.edu/dysci/uwex/nutritn/spreadsheets/FEEDVAL University of Wisconsin, Madison, WI.

BFBB. (2003), Byproduct Feed Bulletin Board, agebb.missouri.edu/dairy/byprod/bplist.asp Departments of Agricultural Economics and Animal Science, University of Missouri, Columbia, MO.

Arosemena, A., DePeters, E. J., and Fadel, J. G. (1995), Anim. Feed Sci. Technol. 54, 103–120.

Belyea, R. L., Steevens, B. J., Restrepo, R. R., and Clubb, A. P. (1989), J. Dairy Sci. 72, 2339–2345.

Belyea, R. L., Rausch, K. D., and Tumbleson, M. E. (2004), Bioresour. Technol. 94, 293–298.

Rausch, K. D., Johnston, D. B., Singh, V., Clevenger, T. E., Tumbleson, M. E., and Belyea, R. L. (2004), in Proceedings of the Corn Utilization Technology Conference, NCGA, St. Louis, MO.

Clevenger, T. E., Johnston, D. B., Belyea, R. L., Singh, V., Tumbleson, M. E. and Rausch, K. D. (2004), in Proceedings of the Corn Utilization Technology Conference, NCGA, St. Louis, MO.

Lory, J. A. (1999) Managing manure phosphorus to protect water quality. Extension Guidesheet G9182. University of Missouri, Columbia, MO.

MASS. (2004), Annual Bulletin 2004, Minnesota Agricultural Statistics Service, USDA and Minnesota Department of Agriculture, St. Paul, MN.

Cicuttini, A., Kollacks, W. A., and Rekers, C. J. N. (1983), Starch/Staerke 35, 149–154.

APV. (2003), APV Dryer Handbook, Invensys APV, Rosemount, IL, p. 57.

Kollacks, W. A. and Rekers, C. J. N. (1988), Starch/Staere 40, 88–94.

Singh, V. and Eckhoff, S. R. (1996), Cereal Chem. 73, 716–720.

Singh, V. and Eckhoff, S. R. (1997), Cereal Chem. 74, 462–466.

Singh, V., Moreau, R. A., Hicks, K. B., and Eckhoff, S. R. (2000), Cereal Chem. 78, 46–49.

Wahjudi, J., Xu, L., Wang, P., et al. (2000), Cereal Chem. 77, 640–644.

Singh, V., Moreau, R. A., Doner, L. W., Eckhoff, S. R., and Hicks, K. B. (1999), Cereal Chem. 76, 868–872.

Singh, V., Panchal, C. B., and Eckhoff, S. R. (1999), Cereal Chem. 76, 846–849.

Taylor, F., McAloon, A. J., Craig, Jr., J. C., Yang, P., Wahjudi, J., and Eckhoff, S. R. (2001), Appl. Biochem. Biotechnol. 94, 41–49.

Moreau, R. A., Singh, V., Eckhoff, S. R., Powell, M. J., Hicks, K. B. and Norton, R. A. (1999), Cereal Chem. 76, 449–451.

Johnston, D. B. and Singh, V. (2001), Cereal Chem. 78, 405–411.

Johnston, D. B. and Singh, V. (2004), Cereal Chem. 81, 626–632.

Johnston, D. B., McAloon, A. J., Moreau, R. A., Hicks, K. B., and Singh, V. (2005) JAOCS 82, 603–608.

Wu, Y. V. (1988), Cereal Chem. 65, 345–348.

Wu, Y. V. (1988), Cereal Chem. 65, 105–109.

Wu, Y. V. and Sexson, K. R. (1985), JAOCS 62, 92–96.

Wu, Y. V., Sexson, K. R., and Wall, J. S. (1983), Cereal Chem. 60, 248–251.

Templin, T. L., Johnston, D. B., Singh, V., Tumbleson, M. E., Belyea, R. L., and Rausch, K. D. (2005), Bioresour. Technol, in press.

Thompson, C. I., Rausch, K. D., Belyea, R. L., and Tumbleson, M. E. (2005), Bioresour. Technol. 97, 348–354.

Rausch, K. D., Raskin, L. M., Belyea, R. L., et al., (2005), Cereal Chem. 82, 431–435.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rausch, K.D., Belyea, R.L. The future of coproducts from corn processing. Appl Biochem Biotechnol 128, 47–86 (2006). https://doi.org/10.1385/ABAB:128:1:047

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1385/ABAB:128:1:047