Abstract

Background

In West Bengal, India, a huge amount of lignocellulosic jute waste products, in the form of unutilized cut pieces of jute caddies consisting 65% cellulose, 22.5% hemicellulose, and 11% lignin, is generated from jute industries. Naturally, the high percentage of lignocellulolytic material made it an attractive substrate for the hydrolytic cleavage of lignocellulolytic enzymes, namely xylanases and cellulases. The present study aims for the production of xylanolytic and cellulolytic enzymes by a fungal isolate Penicillium janthinellum MTCC10889 using a cheap medium containing residual jute caddies obtained from jute mill wastes and chemically defined basal medium under submerged fermentation.

Results

The fungal isolate P. janthinellum MTCC10889 is an outstanding producer of endoxylanase and also cellulase. A central composite design was applied to optimize its lignocellulolytic as well as cellulolytic enzyme production in submerged-state fermentation. The impact of three quantitative variables, namely pH, temperature, and substrate concentrations, on enzyme production was investigated by using a chemically defined basal medium supplemented with jute caddy as substrate. Such optimum conditions were as follows: pH 7.47, temperature of 30.35°C, and substrate concentration of 1.70% for endoxylanase, and pH 7.51, temperature of 29.69°C, and substrate concentration of 2.11% for cellulase production.

Conclusions

A combination of one-factor-at-a-time approach is replaced by response surface methodology using central composite design, which resulted in 3.08- and 3.84-fold increases in the yields of endoxylanase (1,750 IU/ml) and endoglucanase (192 IU/ml), respectively. The highest endoxylanase and endoglucanase productions under optimized conditions were achieved within 48 h of growth.

Similar content being viewed by others

Introduction

In India, lignocellulosic agricultural byproducts constitute staple ruminant feed supplement with small quantity of green foliage, oil cakes, wheat, or rice bran (Kamra 2007). Therefore, only 60% to 65% of this holocellulose is available to the animals as energy source. Arabinoxylan is the major non-starch polysaccharide content in animal feed such as wheat straw and rice straw which can be easily digested by endoxylanase with associated enzymes. The cumulative action of these enzymes decreases gut viscosity and increases productive performance and nutrient digestibility (Odetallah et al. 2002). On the other hand, the diets of farm animals, if supplemented with cellulases, will enhance fiber digestion to improve feed utilization and animal performance (Murad and Azzaz 2010).Therefore, a blend of endoxylanase and endoglucanase will definitely improve the digestive activity of farm animals (Santos et al. 2004) by eliminating anti-nutritional factors present in grains or vegetables, degrading certain cereal components, increasing the nutritional value of feed, and/or by supplementing the animals' own digestive enzymes (Karmakar and Ray 2011a).

Endoxylanases (E.C.2.8.1.8), a group of hemicellulolytic enzymes, are required for the hydrolysis of β-1,4-xylans present in lignocellulosic materials (Kheng and Omar 2005), whereas endoglucanase (E.C.3.2.1.4) is a type of cellulase that cleaves beta linkages at random, commonly in the amorphous part of cellulose (Karmakar and Ray 2011b).

In spite of the commercial significances as digestive aid in animal feed, their bulk production is seriously hindered due to their high cost of production. Hence, the use of an inexpensive substrate and an efficient fermentation process are essential for commercial viability, and above all, a hyper-productive microbial strain capable of synthesizing these enzymes utilizing the lignocellulosic agro and industrial wastes is necessary. Therefore, these unutilized jute fibers could be easily utilized for the commercial production of these two enzymes that could be employed for the nutritional improvement of lignocellulosic feed stuff (Goyal et al. 2008).

Since jute processing is a major industry in India and jute caddies are imposing significant pollution problem in and around the jute industries, the development of a process for the successful utilization of these wastes becomes a need of the hour. As far as the literature study is concerned, no report is available on the production of any value-added product like enzyme, sugar, etc. from jute caddies; extensive research on the exploitation of these wastes as renewable resources is warranted.

The present paper deals with the optimization of major cultivation parameters like pH, temperature, and substrate concentration in submerged fermentation of waste jute caddies by Penicillium janthinellum for the simultaneous production of endoxylanase and endoglucanase, with the help of central composite design using response surface methodology. Further, the application of statistical experimental design techniques in fermentation process development can result in the improvement of product yield, reduce process variability, give a closer confirmation of the output response to nominal, and reduce overall costs (Pansuriya and Singhal 2010). The response surface methodology was proven to be a more cost- and time-saving method than classical one-at-a-time or mathematical methods (Siva Kiran et al. 2010).

Methods

Microorganism

The working strain P. janthinellum MTCC 10889 (Kundu and Ray 2011), isolated from the decaying-vegetation-enriched soil of West Bengal, India, was used for the production of the enzymes.

Chemicals

All chemicals used were of analytical grade. Jute caddies were collected from a jute mill as leftover residues, dried, pulverized as 40 mesh particle size, and were supplemented in the culture media in place of pure xylan.

Cultivation of the strain in submerged-state of fermentation

The strain was cultivated in 100-ml Erlenmeyer flasks, each containing 10 ml of basal medium composed of 0.9 g/l peptone, 0.4 g/l (NH4)2HPO4, 0.1 g/l KCl, and 0.1 g/l MgSO4.7H2O and jute caddies of different concentrations at variable pH and temperature (Tables 1 and 2).

Experimental design of the central composite design for the three factors of production and experimental values for enzyme production in liquid-state fermentations of jute caddies by P. janthinellum.

Enzyme extraction and assay

The cultures, after 48 h of growth, were centrifuged at 10,000 rpm for 5 min at 4°C, and the supernatant was used as the crude enzyme. To measure the activity of endoxylanase, the assay mixture (1 ml) containing an equal volume of enzyme and 1% (w/v) oat spelt xylan (Sigma, St. Louis, MO, USA) in 0.1 M phosphate buffer (pH 6) was incubated at 60°C for 10 min (Kundu and Ray 2011). Similarly, the activity of endoglucanase was estimated by incubating the assay mixture (1 ml) containing an equal volume of enzyme and 1% (w/v) CMCellulose (Sigma) in 0.1 M phosphate buffer (pH 6) at 37°C for 10 min. The reducing sugar released in each case was measured by the dinitrosalicylic acid method (Bernfeld 1955) taking xylose and glucose as respective standards. Blanks were prepared with inactivated enzymes. One unit of endoxylanase and one unit of endoglucanase were defined as the amount of enzyme that liberated 1 μmole of xylose and 1 μmole of glucose respectively from their respective substrates per milliliter per minute of reaction.

Methodology and design of experiments

Design-Expert version 7.1.6 (Stat-Ease, Inc., Minneapolis, USA) was used for the analysis of experimental data and to plot response surface. Analysis of variance (ANOVA) was used to estimate the statistical parameters. The response surface methodology (RSM) was used to determine the optimum operational conditions for the process. A regression model containing three linear (β1, β2, β3), three quadratic (β11, β22, β33), three interaction (β12, β23, β13), and intercept β0 terms is used. The overall second-order polynomial mathematical relationship of the response Y and the three variables, i.e., A denoted as pH, B was temperature (°C), and C indicated the substrate concentration (% (w/v)) could be approximated by the quadratic Equation 1.

Determination of cultivation time

The strain of P. janthinellum MTCC10889 was cultivated under optimized conditions separately for endoxylanase and endoglucanase production in submerged fermentation of waste jute caddies for 24 to 120 h to detect the production kinetics of these two enzymes. Each set of experiment was triplicated, and their average value was taken.

Results and discussion

Effect of variables on endoxylanase activity

On the basis of the quadratic polynomial equation of response surface model (Equation 1), the present model and data analysis not only allowed the definition of optimum conditions for endoxylanase activity but also showed the combined effect of independent variables such as pH (A), temperature (B), and substrate concentration(C) on the endoxylanase activity in terms of coded factors in Equation 2.

Statistical testing of the model was performed with Fisher's statistical test for ANOVA. The quadratic regression showed that the model was significant because the P value of the F test is less than 0.05 (F value = 127.11) (Table 3). The nonsignificant value of 1.20 for the lack of fit showed that the quadratic model adequately fits the observed data for the present study. The value of the determination coefficient is 0.991 (the closer the R2 value is to 1.0, the better is the model fitness to the experimental data), which indicated that the model could explain 99.1% of the variance in the results. This supported the fact that the data were less variable, more uniform, and homogeneous. A small coefficient of variation value of 8.1% clearly indicated a very high degree of precision and a good deal of reliability of the experimental values (Table 3).

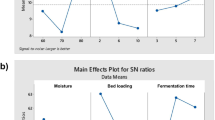

P values less than 0.05 for A2, B2, and C2 indicated that the quadratic model terms were significant. By constructing a normal probability plot of the residuals, a check was made for the normality assumption, as given in Figure 1. The normality assumption was satisfied as the residual plot approximated along a straight line after reviewing all the statistical outputs for design evaluation and three-dimensional plots, which indicated the design points and polynomial fitness of the model (Figure 2a,b,c).

Response surface plots for endoxylanase production. a Response surface plot showing the effect of pH and temperature on endoxylanase production with other variable constant at middle level. b Response surface plot showing the effect of pH and substrate concentration on endoxylanase production with other variable constant at middle level. c Response surface plot showing the effect of substrate concentration and temperature on endoxylanase production with other variable constant at middle level.

Effect of variables on endoglucanase activity

RSM was employed to characterize the individual and interactive effects of pH (A), temperature (B), and substrate concentration (C) on endoglucanase production.

The ANOVA result showed that the value of R2 for the response was in reasonable agreement with the adjusted R2. P value obtained for the model was <0.001, indicating that the mathematical models generated were highly significant. The mathematical models' signal-to-noise ratio was well in control, as assessed by the values of adequate precision (24.01), which were quite higher than the standard value of 4 (Design-Expert guide). In the present experiment, the lower value of coefficient of variation (11.50) indicated better precision and reliability of the experiments (Box et al. 1978). The three-dimensional response surfaces for the three variables (Figure 3a,b,c) showed a nonlinear relationship between the independent variables. The residuals from the least squares fit played an important role in judging model adequacy (Myers and Montgomery 2002). By constructing a normal probability plot of the residuals, a check was made for the normality assumption, as given in Figure 3. The normality assumption was satisfied as the residual plot approximated along a straight line. The plot (Figure 4) was satisfactory; hence, we could conclude that the empirical model was adequate to describe the endoglucanase activity by response surface. Normally, a regression model having an R2 value higher than 0.9 could be considered as having a very high correlation (Haaland 1989). The value of R closer (correlation coefficient) to 1 indicated the better correlation between the experimental and predicted values. Here, the value of R2 (0.984) for Equation 3 indicated a close agreement between the experimental results (Table 4).

Response surface plots for endoglucanase production. a Response surface plot showing the effect of pH and temperature on endoglucanase production with other variable constant at middle level. b Response surface plot showing the effect of pH and substrate concentration on endoglucanase production with other variable constant at middle level. c Response surface plot showing the effect of substrate concentration and temperature on endoglucanase production with other variable constant at middle level.

Validation of the model

The statistical optimal values of variables were obtained from the central composite design, and the response at the different points yielded maximum endoxylanase and endoglucanase production. A repeat fermentation of jute caddy wastes for the highest production of enzymes by P. janthinellum MTCC 10889 under optimal conditions was carried out for verification of the optimization. The maximal endoxylanase and endoglucanase production found under optimal conditions were 1,750 and 192 IU/ml, respectively, which was 5.5% and 8.57% less than the predicted values, respectively.

Effect of cultivation time

The highest endoxylanase and endoglucanase production could be attained within 48 h of cultivation (Figure 5), after which the production of both enzymes gradually reduced probably due to the gradual depletion of nutrients available to the fungus. This rapid production of both enzymes made the strain economically important.

Conclusions

After statistical optimization of the major physicochemical parameters for synthesizing the enzymes, the synthesis resulted in endoxylanase production (1,750 U/ml) at pH 7.47, temperature 30.35°C, and substrate concentration 1.70% against the predicted activity of 1,852.37 U/ml, and an endoglucanase production (192 U/ml) at pH 7.51, temperature 29.69°C, and substrate concentration 2.11% against the predicted activity of 210.359 U/ml, indicating model accuracy. Hence, P. janthinellum may offer new options for the simultaneous expression of xylanolytic and cellulolytic enzymes for commercial purpose.

Abbreviations

- ANOVA:

-

Analysis of variance

- RSM:

-

Response surface methodology

- R:

-

Correlation coefficient

References

Bernfeld P: Amylases α and β. Methods of Enzymol 1955, 1: 149–150.

Box GEP, Hunter WG, Hunter JS: Statistics for experiments. New York: Wiley; 1978:291–334.

Goyal M, Kalra KL, Sareen VK, Soni G: Xylanase production with xylan rich lignocellulosic wastes by a local soil isolate of Trichoderma viride . Braz J Microbiol 2008, 39: 535–541. 10.1590/S1517-83822008000300025

Haaland PD: Separating signals from the noise. In Experimental design in biotechnology. 1989 edition. New York: Marcel Dekker; 1989:61–83.

Kamra DN: Lignocellulose biotechnology: future prospects. New Delhi: I.K. International; 2007:179–205.

Karmakar M, Ray RR: Production of extracellular endoglucanase by the hyperproductive pellets of Rhizopus oryzae . World J Sci Technol 2011, 6: 26–32.

Karmakar M, Ray RR: Current trends in research and application of microbial cellulases. Res J Microbiol 2011, 6: s41-s53. 10.3923/jm.2011.41.53

Kheng PP, Omar IC: Xylanase production by a local fungal isolate, Aspergillus niger USM AI 1 via solid state fermentation using palm kernel cake (PKC) as substrate. Songklanakarin. J Sci Technol 2005,27(2):325–336.

Kundu A, Ray RR: Agrowaste utilization and production of extra cellular endoxylanase by Penicillium janthinellum MTCC 10889 in solid state fermentation. Int J Cur Res 2011,3(7):120–124.

Murad HA, Azzaz HH: Cellulase and dairy animal feeding. Biotechnol 2010,9(3):238–256.

Myers RH, Montgomery DC: Response surface methodology. New York: Wiley; 2002.

Odetallah NH, Parks CW, Ferket PR: Effect of wheat enzyme preparation on the performance characteristics of tom turkeys fed wheat-based rations. Poult Sci 2002,81(7):987–994.

Pansuriya RC, Singhal RS: Response surface methodology for optimization of production of lovastatin by solid state fermentation. Braz J Microbiol 2010,41(1):164–172. 10.1590/S1517-83822010000100024

Santos AA Jr, Ferket PR, Grimes JL, Edens FW: Dietary supplementation of endoxylanases and phospholipase for turkeys fed wheat-based rations. Int J Poult Sci 2004,3(1):20–32.

Siva Kiran RR, Konduri R, Rao GH, Madhu GM: Statistical optimization of endopoly galacturonase production by overproducing mutants of Aspergillus niger in solid-state fermentation. J Biochem Tech 2010,2(2):154–157.

Acknowledgment

The authors are thankful to the Life Science Research Board, Defense Research and Development Organization (DRDO), New Delhi, India, for the financial assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

AK carried out the overall fermentation studies with special reference to the optimization of endoxylanase production. MK carried out the studies on endoglucanase production and performed the statistical analysis. RRR designed the protocol, drafted the manuscript and supervised the entire work. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Kundu, A., Karmakar, M. & Ray, R.R. Simultaneous production of animal feed enzymes (endoxylanase and endoglucanase) by Penicillium janthinellum from waste jute caddies. Int J Recycl Org Waste Agricult 1, 13 (2012). https://doi.org/10.1186/2251-7715-1-13

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-7715-1-13