Abstract

Swanepoel method is employed for spectroscopic determination of optical properties of Cu3N thin film using transmittance data. Investigated films have been deposited using reactive magnetron sputtering system. Deposition time was 9 to 21 min. Refractive index, absorption coefficient, and bandgap energy of the samples are determined. Thickness of the films is calculated by Swanepoel method, and result is compared with the thickness of the films measured by profilmeter. It is shown that Swanepoel method is a reliable way to calculate the optical constants of thin films when the transmittance spectrum of the film is influenced by wavelike patterns due to reflection of the probe beam from different interfaces.

Similar content being viewed by others

Background

There is convenient method with using few known equations to determine the optical constants of semiconductor and insulator thin films based on their reflectance and transmittance spectrum [1]. However, when thickness of the film is in the range of micrometer, some wavelike patterns due to interaction of probe beam reflected from different interfaces appear in transmittance and reflectance spectrum. These patterns are a source of errors in calculating the optical parameters of thin film such as refractive index and absorption coefficient. Actually, this wavelike patterns which appeared in all results are not true. In this case, Swanepoel method can be used as a solution for this problem. In fact, Swanepoel method is a way to simulate the wavelike patterns in the transmittance spectrum with smooth curves. Other advantage of this method is that the reflectance of the sample is not required for calculating optical parameters. Because reflectance of the sample can be influenced by the roughness of the sample, it can be another source of error in calculating the optical parameters of the thin films.

Copper nitride (Cu3N) with the structure of cubic anti-ReO3, one kind of excellent semiconductors with many extraordinary properties due to its small indirect band gap, has obtained considerable attention in recent years as a new material applicable for optical storage devices and high-speed integrated circuits. At very low temperature (about 300 to 470°C), Cu3N decomposes into Cu and N2 and becomes a conductor from a semiconductor. So the low decomposition temperature and discriminating optical properties of the compound Cu3N are applicable for optical read-only memory disks by generating microscopic Cu-metal spots on Cu3N film by performing local laser heating. On the other hand, its optical reflectivity in visible and infrared range is far smaller than that of pure Cu [2–6].

In this work, with the goal of introducing the Swanepoel theory [7] as a precise method to characterize the optical parameters of thin films, the optical properties of Cu3N thin films are investigated. The transmittance spectra of Cu3N thin films over the wavelength range 200 to 2,000 nm at room temperature are measured. These films were deposited on glass substrate by reactive DC magnetron sputtering of a Cu target with 50% nitrogen contents in the working gas at different sputtering times. Optical transmission spectra of films are analyzed to determine their optical constants such as refractive index, absorption coefficient using Swanepoel method, and the effect of sputtering parameters on the optical properties of films are discussed. Details of the structure of films are reported in reference [6].

This manuscript is organized as follows: After this introduction, the experimental setup is presented in section 2. Section 3 is devoted to description of Swanepoel method, results, and discussion. All stages to extract refractive index, absorption coefficient, and band gap energy are explained in detail in this section; and finally, a discussion on the behavior of optical parameters of all deposited films is presented. Conclusion of the manuscript can be read in section 4.

Methods

Copper nitride thin films were sputtered on BK7 glass substrate, by using a cylindrical direct current reactive magnetron sputtering system. Before deposition, substrates were cleaned by ultrasonic waves in acetone and alcohol, and dried by blowing air. In the deposition process, no external heating was provided. The base pressure of the vacuum chamber just before sputtering was 2 × 10−4 mbar. During the sputtering experiment, the pressure was maintained at 6 × 10−2 mbar. A pure copper (99.99%), 30 mm diameter and 195 mm in height, was used as the target. The working gas was a mixture of 99.999% pure nitrogen and 99.999% pure argon with the same percent N2/Ar (50%). The distance between the substrate and the target was 30 mm. The discharge current was 200 mA at the voltage difference of about 700 V, and deposition time was varied between 9 and 21 min. Uniform magnetic field of 400 Gauss was generated in the sputtering reactor parallel to the axis of cylindrical chamber by a solenoid.

After film deposition, X-ray diffraction (XRD) was performed on STOE-XRD diffractometer using Cu- Kα line (l = 0.15406 nm). Change in transmittance spectrum of the samples was measured by a Varian Cary-500 spectrophotometer (Varian Inc., CA, USA) at room temperature, and a Dektak3 profilmeter was employed to measure the thickness of the growth films.

Swanepoel method, results and discussion

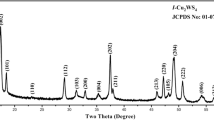

Films structure

The XRD patterns of Cu3N films deposited on glass substrate are shown in Figure 1. The XRD analysis reveals that the films are polycrystalline of cubic Cu3N structure with peaks at 2θ = 23.54°, 41.19°, and 47.88° corresponding to Cu3N(100), Cu3N(111), and Cu3N(200) orientations, respectively. Grain size of the sputtered films is calculated by Scherrer's formula, and their thickness is measured by profilmeter which is between 360 and 770 nm as well as deposition rate of samples are presented in Table 1. The XRD patterns of samples show that the crystallinity of deposited films is increased with increasing the thickness of deposited films, i. e., deposition time. Optical transmittance spectra of deposited films are presented in Figure 2. Spectra show an increase at wavelengths between 600 and 800 nm, and the wavelike structures can be seen in all patterns due to the interaction of the beam transmitted from different interfaces.

Swanepoel method

The practical condition for a thin film on a transparent substrate is shown in Figure 3. In this figure, d, n, α, and T denote the thickness, refractive index, absorption coefficient, and transmission of the film, respectively. The transparent substrate has a thickness of several orders of magnitude larger than d with index of refractions and absorption coefficient αs = 0 and transmittance Ts. The index of refraction for air is taken to be n0 = 1. If the thickness d is uniform, interference effects give rise to the spectrum, shown by the full curve in Figure 4. The transmittance spectrum of sample 5 is presented in Figure 4. This sample is chosen to be described by Swanepoel method for extracting the optical parameters. These interference fringes can be used to calculate the optical constants of the film. For the sake of comparison, we have also included the transmittance spectrum of the bare substrate, which is shown by dotted line as Ts. Cu3N thin film strongly absorbs the electromagnetic wave with wavelengths smaller than 600 nm. The basic equation for interference fringes is

where m is an integer for maxima and half integer for minima, n is refractive index, d is the thickness of the film, and λ is wavelength. The transmission T for the normal incidence resulted from the interference of the wave transmitted from three interfaces can be written as [7]:

where

For maximum and minimum points of interferences cos (φ) = 1, so TM and Tm curves as the upper and lower bounding functions of transmittance can be found by fitting the two below curves to these points as

If Ts is the maximum value of the transmission of substrate, then substrate refractive index s can be given by the following equation:

The upper bounding function TM passes through the maxima of the spectrum and Tm through the minima is shown in Figure 4, where the envelope for a simulated transmission curve is shown.

From Equations 4 and 5, we have

The right hand side of Equation 7 is independent of the thickness of the film. Substituting C and A from Equation 3 into Equation 7 leads to

where

For the Cu3N thin film which is shown in Figure 4, using the least square method the fitted curves are

By using these equations in Equations 8 and 9, taking s = 1.5, the refractive index of Cu3N sample in the range of fitted curves can be obtained which is presented in Figure 5. With increasing of wavelength, the refractive index of Cu3N thin film is increased from 1.9 to 2.4. We attribute this to strong absorption of Cu3N and nitrides films in this range. Obtained magnitudes for n are in good agreement with other reports [8, 9]. The magnitudes of refractive index with the magnitudes of exact maxima and minima of transmission (Figure 4) of sample 5 are presented as n1 in Table 2. A curve of the from

can be fitted to these points with a0 = 2.594, and a1 = −1.845 × 104. This curve is the second order Cauchy dispersion relation. This empirical fit was derived by Cauchy based on a theory of light propagation later proven to be false. Nevertheless, it is often used by optical spectroscopists for its simplicity [10]. Extracted n(λ) and its accompanying Cauchy fit are shown in Figure 6.

If n1 and n*1 are the refractive indices calculated from two consecutive maxima or minima corresponds to two wavelengths of λ1 and λ2, then the thickness of the film d can be obtained from [7]:

The thickness obtained from Equation 11 is very sensitive to the uncertainty in the value of the refractive index which is derived from Equation 8. The values of film thickness calculated from Equation 11 are shown as d1 in Table 2.

If the dispersion of refractive index is negligible (which is usually the case well away from the absorption edge), the order of interference m at the maxima of transmission spectra for wavelength λ1 is:

Where λ1 and λ2 are the wavelengths of two adjacent transmission maxima (λ1 > λ2), and the symbol (x) stands for nearest integer. Another magnitude for thickness can be found by using m from Equation 12 in Equation 1, which is indicated as d2.

Different regions of strong, medium, and weak absorption are indicated in Figure 4. For the strong absorption region where interference fringes disappear, the absorption coefficient α, is given by [7].

in which T0 = Ax/B, and d is the film thickness. The n and s are the refractive indices of the film and substrate, respectively. In the spectral region of medium absorption where interference fringes appear distinctly in the transmission spectra, α can be obtained by [7]

where

Absorption coefficient of Cu3N thin film for strong and medium regions is presented in Figure 7. It is noticeable that the wavelike patterns due to interaction of probe beam reflected from different interfaces will be appeared in the optical absorption coefficient which is evaluated from the transmittance data using the known relation α = (1/d)ln(1/T). Of course, they cannot be true [6].

The optical energy gap Eg is another important quantity that characterizes semiconductors and dielectric materials since it has a paramount importance in the design and modeling of such materials [11]. An approximate functional dependency of α on the energy of photons is given by the expression [12]:

where A is a dimensional constant, Eg is the optical bandgap, and p is an index representing the transition order. For indirect optical bandgap, p = 1/2, and the curve (αE)1/2E tends asymptotically towards a linear section; other values of p (generally 2) suggest a direct optical bandgap. The structure of Cu3N prepared in this study has an indirect optical band gap, as is shown by the plot of (αE)1/2 versus E in Figure 8. Consequently, Eg is the intersection of E axis with a fit to the linear section of the (αE)1/2E curve. Through this procedure, we found E g = 1.9 eV for the Cu3N thin film of sample 5 as is shown in Figure 8. The optical bandgap energy of all samples extracted by using the Swanepoel method data is exactly the same with the magnitudes extracted from the last data, which show that the interference in transmittance spectrum does not make noticeable changes in the absorption edge magnitudes.

Results and discussion

Extracted refractive index and thickness of other sputtered Cu3N samples by Swanepoel method are presented in Tables 3, 4, 5 and 6. The magnitudes of d2 are closer to the magnitudes of thickness measured by profilmeter in comparison with d1. The same results are also presented in reference 7.

Two methods for calculating the thickness are introduced. In the first method, thickness of the film can be determined by the use of corresponding wavelength at of Equation 8 maxima, and minima points occurs as introduced in Equation 11. In this case, refractive index should also take into account. In the second method, Equation 10 is used. As can be seen, the distribution of thickness deposited films calculated from Swanepoel method is very large and far from measured magnitudes. Error is more than 20%. One source of error is the first fitting procedure of TM and Tm to transmittance curve. Especially, when the number of maxima or minima on transmittance curve is less than three, the error is larger. Calculated magnitudes for n are more accurate and usually n1 = n2. This is because for calculating the n, the exact maxima or minima on transmittance curve are used.

Variations of refractive indexes of samples calculated by Swanepoel method in the range of 500 to 2,000 nm wavelength of electromagnetic wave are shown in Figure 9. Extracted magnitudes for n between 2.06 and 2.28 confirm that deposited films on substrates are uniform. Change in refractive index of deposited films at 650, 690, and 730 nm, corresponds to 1.9, 1.8, and 1.7 eV which are related to the bandgap energy and thickness of the samples. Bandgap energy of samples is decreased from sample 1 to 3 and then is increased. Considering the magnitude of bandgap energy and thickness of films with their refractive index shows that the refractive index of samples is decreased and then is increased with their thickness when the photon energy is smaller than the bandgap energy. This behavior is reversed when the photon energy is larger than the bandgap energy. The refractive index of deposited films is approximately constant for two last samples when the thickness of samples is larger than 620 nm. In fact, by increasing the thickness and crystallinity of thin films, absorption and dispersion in the layers will increase which leads to increasing the refractive index. This can be due to the density of deposited films. Increasing the crystallinity of films in (100) direction besides increasing the thickness of deposited films leads to increasing their density. Increasing the density of films increases their refractive index when the energy of photons is smaller than the bandgap energy of films. As is presented in Figure 9, when energy of photons is larger than the bandgap energy of films, the dispersion of refractive index occurs [1].

Absorption coefficient of Cu3N samples for photons at 1.7, 1.8, and 1.9 eV energies which are applied energies for copper nitride thin films are plotted in Figure 10. As is expected, the absorption coefficient of samples is increased with increasing the photon energy. However, the rate of this change depends on whether the photon energy is larger or smaller than the energy of bandgap. For photons with energy larger than the band gap energy of film absorption, coefficient is increased noticeably. It is clear that α must be a strong function of the energy hν of the photons. For hν < E g (direct), no electron hole pairs can be created, the material is transparent, and α is small. For hν ≤ E g (direct), absorption should be strong.

Conclusions

In this work, the Swanepoel method is introduced practically to determine the optical characteristics of Cu3N thin films deposited on BK7 glass substrate. It is shown that when the transmittance spectrum of films is affected by the wavelike structure patterns due to interference of probe beam after successive reflections from different interfaces, using Swanepoel method for determination of optical constants of deposited films leads to reducing error significantly. Besides, measuring the film thickness by profilmeter, two other ways based on refractive index and interference pattern are presented for calculating the thickness. Results show that the magnitude calculated from the second way is closer to the measured magnitudes. It is observed that appeared wavelike patterns in the transmittance spectrum do not make error in calculating the magnitude of bandgap energy of the thin films. Some fluctuation can be observed in the magnitude of refractive index and absorption coefficient of samples which tends to zero when the thickness of the films is increased.

References

Dorranian D, Dejam L, Sari AH, Hojabri A: Effect of nitrogen content on optical constants of copper nitride thin films prepared by DC magnetron reactive sputtering:. JTA Phys. 2009, 3: 37–41.

Benjemaa N, Abdi REI, Carvou E: Numerical and experimental study of the contact resistance for high copper alloys in force domain 1–100N. Eur Phys. J. Appl. Phys. 2010, 49: 22906. 10.1051/epjap/2009208

Gallardo Vega C, De la Cruz D: Study of the Structure and Electrical Properties of the Copper Nitride Thin Films Deposited by Pulsed Laser Deposition. Appl. Surf. Sci. 2006, 252: 8001–8004. 10.1016/j.apsusc.2005.10.007

Du Y, Ji AL, Ma LB, Wang YQ, Cao ZX: Electrical conductivity and photoreflectance of nanocrystalline copper nitride thin films deposited at low temperature. J. Crystal Growth 2005, 280: 490–494. 10.1016/j.jcrysgro.2005.03.077

Dorranian D, Dejam L, Sari AH, Hojabri A: Structural and optical properties of copper nitride thin films in a reactive Ar/N2 magnetron sputtering system. Eur. Phys. J. Appl. Phys. 2010, 50: 20503. 10.1051/epjap/2010040

Dorranian D, Mosayebian G: Experimental study of the electrical properties of copper nitride thin films prepared by dc magnetron sputtering. Eur. Phys. J. Appl. Phys. 2011, 53: 10501. 10.1051/epjap/2010100298

Swanepoel R: Determination of the Thickness and Optical Constants of Amorphous Silicon. J. Phys. E 1983, 16: 1214–1224. 10.1088/0022-3735/16/12/023

Sivasankar Reddy A, VenkataSubba Reddy K, Uthanna S, Sreedhara Reddy P: Copper nitride films deposited by dc reactive magnetron sputtering. J. Mater. Sci.: Mater. Electron 2007, 18: 1003–1008. 10.1007/s10854-007-9120-0

Odeh IM: Fabrication and optical constants of amorphous copper nitride thin films prepared by ion beam assisted dc magnetron reactive sputtering. J. Alloys Compd. 2008, 454: 102–105. 10.1016/j.jallcom.2006.12.020

Ozgur U: Alivov YaI, Liu C, Teke A, Reshchikov MA, Dogan S, Avrutin V, Cho SJ. Morkoc H: J. Appl. Phys. 2005, 98: 041301.

Poelman D, Smet PF: Methods for the Determination of the Optical Constants of Thin Films from Single Transmission Measurements: A Critical Review. J. Phys. D: Appl. Phys. 2003, 36: 1850–1857. 10.1088/0022-3727/36/15/316

Fox M: Optical properties of solids. 1st edition. Oxford University Press, Oxford; 2002.

Author information

Authors and Affiliations

Corresponding author

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Dorranian, D., Dejam, L. & Mosayebian, G. Optical characterization of Cu3N thin film with Swanepoel method. J Theor Appl Phys 6, 13 (2012). https://doi.org/10.1186/2251-7235-6-13

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-7235-6-13