Abstract

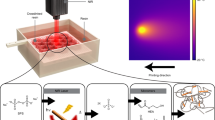

In view of the wide use of titanium dioxide, more and more approaches to 3D printing of materials based on it have recently been developed, the most promising if which remains stereolithography 3D printing owing to high resolution and low power consumption. It was studied how the degree of crystallinity of titanium dioxide affects both the properties of the obtained suspensions for stereolithography 3D printing, and the sinterability of the printed bulk materials. It was shown that the use of amorphous titanium dioxide as a precursor increases the fraction of the inorganic phase in the suspension, which leads to a significantly smaller shrinkage in sintering. Despite the high critical energy of polymerization and the low photosensitivity of the produced suspensions, the use of amorphous titanium dioxide enabled one to completely remove the polymer binder by high-temperature annealing without significant deformation of the printed samples.

Similar content being viewed by others

REFERENCES

K. Nakata and A. Fujishima, J. Photochem. Photobiol., C 13, 169 (2012). https://doi.org/10.1016/j.jphotochemrev.2012.06.001

T. Sreethawong, Y. Yamada, T. Kobayashi, et al., J. Mol. Catal. A: Chem. 241, 23 (2005). https://doi.org/10.1016/j.molcata.2005.07.009

T. An, H. Yang, W. Song, et al., J. Phys. Chem. A 114, 2569 (2010). https://doi.org/10.1021/jp911349y

V. K. Ivanov, V. D. Maksimov, A. S. Shaporev, et al., Russ. J. Inorg. Chem. 55, 150 (2010). https://doi.org/10.1134/S0036023610020026

I. V. Kolesnik, V. A. Lebedev, and A. V. Garshev, Nanosyst. Physics, Chem. Mat 9 (3), 401. https://doi.org/10.17586/2220-8054-2018-9-3-401-409

V. A. Lebedev, D. A. Kozlov, I. V. Kolesnik, et al., Appl. Catal. 195, 39 (2016). https://doi.org/10.1016/j.apcatb.2016.05.010

M. A. Anderson, M. J. Gieselmann, and Q. Xu, J. Membr. Sci. 39, 243 (1988). https://doi.org/10.1016/S0376-7388(00)80932-1

A. Oun, N. Tahri, S. Mahouche-Chergui, et al., Sep. Purif. Technol. 188, 126 (2017). https://doi.org/10.1016/j.seppur.2017.07.005

O. L. Galkina, V. K. Ivanov, A. V. Agafonov, et al., J. Mater. Chem. B 3, 1688 (2015). https://doi.org/10.1039/C4TB01823K

O. L. Galkina, K. Onneby, P. Huang, et al., J. Mater. Chem. B 3, 7125. https://doi.org/10.1039/C5TB01382H

Z. Li, Y. Qu, X. Zhang, et al., Acta Biomater. 5, 2189 (2009). https://doi.org/10.1016/j.actbio.2009.02.013

M. Rasoulianboroujeni, F. Fahimipour, P. Shah, et al., Mater. Sci. Eng. C 96, 105 (2019). https://doi.org/10.1016/j.msec.2018.10.077

X. Wang, M. Jiang, Z. Zhou, et al., Composites, Part B 110, 442 (2017). https://doi.org/10.1016/j.compositesb.2016.11.034

Z. Chen, Z. Li, J. Li, et al., J. Eur. Ceram. Soc. 39, 661 (2019). https://doi.org/10.1016/j.jeurceramsoc.2018.11.013

A. K. Petrov, Inorg. Mater. 53, 1349 (2017). https://doi.org/10.1134/S0020168517110073

D. S. Larionov, M. A. Kuzina, P. V. Evdokimov, et al., Russ. J. Inorg. Chem. 65, 312 (2020). https://doi.org/10.1134/S0036023620030079

A. Tikhonov, P. Evdokimov, E. Klimashina, et al., J. Mech. Behav. Biomed. Mater. 110, 103922 (2020). https://doi.org/10.1016/j.jmbbm.2020.103922

V. I. Putlyaev, P. V. Yevdokimov, S. A. Mamonov, et al., Inorg. Mater. Appl. Res. 10, 1101 (2019). https://doi.org/10.1134/S2075113319050277

A. Elkoro, L. Soler, J. Llorca, et al., Appl. Mater. Today 16, 265 (2019). https://doi.org/10.1016/j.apmt.2019.06.007

W. Jo, B. J. Yoon, H. Lee, et al., Print. Addit. Manuf. 4, 222 (2017). https://doi.org/10.1089/3dp.2017.0033

A. H. Aleni, N. Kretzschmar, A. Jansson, et al., Ceram. Int. 46, 16725 (2020). https://doi.org/10.1016/j.ceramint.2020.03.248

P. He, X. Tang, L. Chen, et al., Adv. Funct. Mater. 28, 1801121 (2018). https://doi.org/10.1002/adfm.201801121

C. Xu, T. Liu, W. Guo, et al., Adv. Eng. Mater. 22, 1901088 (2020). 10.1002/adem.20190108

F. Mendez-Arriaga, E. de la Calleja, L. Ruiz-Huerta, et al., Mater. Sci. Semicond. Process 100, 35 (2019). https://doi.org/10.1016/j.mssp.2019.04.034

L. Bergamonti, C. Bergonzi, C. Graiff, et al., Water Res. 163, 114841 (2019). https://doi.org/10.1016/j.watres.2019.07.008

L. Chen, X. Tang, P. Xie, et al., Chem. Mater. 30, 799 (2018). https://doi.org/10.1021/acs.chemmater.7b04313

C. Y. Lee, A. C. Taylor, S. Beirne, et al., Adv. Energy Mater. 7, 1701060 (2017). https://doi.org/10.1002/aenm.201701060

X.-M. Duan, H.-B. Sun, K. Kaneko, et al., Thin Solid Films 453–454, 581 (2004). https://doi.org/10.1016/j.tsf.2003.11.126

A. Vyatskikh, A. Kudo, S. Delalande, et al., Mater. Today Commun. 15, 288 (2018). https://doi.org/10.1016/j.mtcomm.2018.02.010

F. Liu, S. Xie, Y. Wang, et al., Rapid Prototyp. J. 24, 1421 (2018). https://doi.org/10.1108/RPJ-03-2017-0041

P. F. Jacobs, Rapid Prototyping & Manufacturing: Fundamentals of StereoLithography (Soc. Manuf. Eng., Dearborn, MI, 1992).

V. Petříček, M. Dušek, and L. Palatinus, Z. Kristallogr. 229, 345 (2014). https://doi.org/10.1515/zkri-2014-1737

S. P. Gentry and J. W. Halloran, J. Eur. Ceram. Soc. 33, 1981 (2013). https://doi.org/10.1016/j.jeurceramsoc.2013.02.033

S. P. Gentry and J. W. Halloran, J. Eur. Ceram. Soc. 35, 1895 (2015). https://doi.org/10.1016/j.jeurceramsoc.2014.12.006

Y. Lin and J. W. Stansbury, Polym. Adv. Technol. 16, 195 (2005). https://doi.org/10.1002/pat.562

V. Tomeckova and J. W. Halloran, J. Eur. Ceram. Soc. 30, 2833 (2010). https://doi.org/10.1016/j.jeurceramsoc.2010.01.027

S. Mubarak, D. Dhamodharan, N. Divakaran, et al., Nanomaterials 10, 79 (2020). https://doi.org/10.3390/nano10010079

A. S. Poluboyarinov, V. I. Chelpanov, V. A. Lebedev, et al., Materials 12, 1472 (2019). https://doi.org/10.3390/ma12091472

Funding

This work was performed under state assignment on basic scientific research for the Kurnakov Institute of General and Inorganic Chemistry, Russian Academy of Sciences, Moscow, Russia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Glyanchenko

Rights and permissions

About this article

Cite this article

Kozlov, D.A., Tikhonova, S.A., Evdokimov, P.V. et al. Stereolithography 3D Printing from Suspensions Containing Titanium Dioxide. Russ. J. Inorg. Chem. 65, 1958–1964 (2020). https://doi.org/10.1134/S0036023620120098

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036023620120098