Abstract

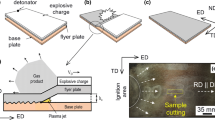

We have presented the results of studying the fine structure of interphase boundaries for a number of composite materials obtained by methods of explosive welding and explosive compacting of powder mixtures. Joints of different metals (titanium-low-carbon steel, copper-tantalum) and metals with refractory carbides (chromium carbide-titanium) have been investigated. Under welding, pairs differed from each other by the type of interaction. It has been found that, in these composites, interphase boundaries exhibit a final thickness on the order of 200 nm, throughout which the composition of the material changes gradually from a composition that corresponds to one of the components of the composite to a composition that corresponds to the second component. It has been shown that the structure of interphase boundaries is complex. With the limited solubility of components along boundaries, two fairly thick crystalline interlayers are detected, the total thickness of which is equal to the total thickness of the boundary; between the interlayers, there is a thin (to 5–7 nm in thickness) interlayer with a crystalline or amorphous structure.

Similar content being viewed by others

References

V. I. Lysak and S. V. Kuz’min, Explosive Welding (Mashinostroenie-1, Moscow, 2005) [in Russian].

V. I. Lysak and S. V. Kuzmin, “Lower boundary in metal explosive welding. Evolution of ideas,” J. Mater. Process. Techn. 212, 150–156 (2012).

A. V. Krokhalev, V. O. Kharlamov, S. V. Kuz’min, and V. I. Lysak, “Regularities of formation of solid alloys from mixtures of chromium carbide powders with titanium with use of energy of explosion,” Izv. Vuzov. Ser. Poroshk. Metall.Funkts. Pokryt, No. 1, 32–37 (2012).

B. A. Greenberg, M. A. Ivanov, V. V. Rybin, et al., “Inhomogeneities of the interface produced by explosive welding,” Phys. Met. Metallogr. 113, 176–189 (2012).

Interfaces in Metal Matrix Composites, Ed. by A. G. Metcalfe (Academic, New York, 1974; Mir, Moscow, 1978).

A. I. Gusev, Nanomaterials, Nanostructures, Nanotechnologies (Fizmatlit, Moscow, 2005) [in Russian].

V. A. Shabashov, V. V. Ovchinnikov, P. P. Mulyukov, et al., “Determination of the ‘grain-boundary phase’ in submicrocrystalline iron by Mössbauer spectroscopy,” Phys. Met. Metallogr. 85, 327–331 (1998).

T. Haubold, R. Birringer, B. Lengeler, and H. Gleiter, “EXAFS studies of nanocrystalline materials exhibiting a new solid state structure,” Phys. Lett. A 135, 461–466 (1989).

D. V. Shtanskii, “Transparent electron microscopy of high resolution in nanotechnological studies,” Ross. Khim. Zh. (Zh. Ross. Khim. Ob-va im. D. I. Mendeleeva) 46(5), 81–89 (2002).

B. S. Murty, M. K. Datta, and S. K. Pabi, “Structure and thermal stability of nanocrystalline materials,” Sādhanā. 28, 23–45 (2003).

P. Keblinski, S. R. Phillpot, D. Wolf, and H. Gleiter, “On the thermodynamic stability of amorphous intergranular films in covalent materials,” J. Eur. Ceram. Soc. 80, 717–732 (1997).

S. Veprek and S. A. Reiprich, “A concept for the design of novel superhard coatings,” Thin Solid Films 268, 64–71 (1995).

V. Ya. Shevchenko, O. L. Khasanov, G. S. Yur’ev, and Yu. P. Pokholkov, “Structural features of ultrafine zirconia as probed by synchrotron X-ray diffraction,” Dokl. Phys. Chem. 377, 121–123 (2001).

D. V. Shtansky, E. A. Levashov, A. N. Sheveiko, and J. J. Moore, “Synthesis and characterization of Ti-Si-C-N films,” Metal. Mater. Trans. A 30, 2439–2447 (1999).

J. Song, A. Kostka, M. Veehmayer, and D. Raabe, “Hierarchical microstructure of explosive joints: Example of titanium to steel cladding,” Mater. Sci. Eng.: A 528, 2641–2647 (2011).

E. A. Ushanova, E. V. Nesterova, S. N. Petrov, et al., “Development of electron-microscopy specimen preparation for investigations of nanostructured bond zones in dissimilar joints by ion milling,” Vopr. Materialoved. 65(1), 110–117 (2011).

Author information

Authors and Affiliations

Additional information

Original Russian Text © V.I. Lysak, S.V. Kuz’min, A.V. Krokhalev, B.A. Grinberg, 2013, published in Fizika Metallov i Metallovedenie, 2013, Vol. 114, No. 11, pp. 1026–1031.

Rights and permissions

About this article

Cite this article

Lysak, V.I., Kuz’min, S.V., Krokhalev, A.V. et al. Structure of boundaries in composite materials obtained using explosive loading. Phys. Metals Metallogr. 114, 947–952 (2013). https://doi.org/10.1134/S0031918X13110069

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X13110069