Abstract

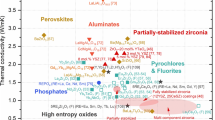

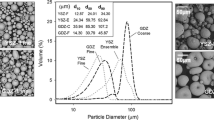

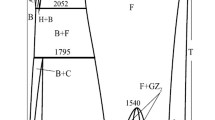

Atmospheric plasma spraying of powder materials has been used to produce thermal barrier coatings (TBCs) based on ZrO2 stabilized with 7 wt % Y2O3, including coatings doped with neodymium and samarium oxides, for state-of-the-art and next-generation high-temperature gas turbine engines. Doping with neodymium and samarium oxides has been shown to reduce the thermal conductivity of the TBCs by 10–20%. At the same time, changes in the phase composition, crystal structure parameters, and microstructure of the TBCs during heat treatment at the service temperature lead to an increase in the thermal conductivity of all the coatings by 50–70%.

Similar content being viewed by others

References

Miller, R.A., Thermal barrier coatings for aircraft engines: history and directions, J. Therm. Spray Technol., 1997, vol. 6, no. 1, pp. 35–42.

Levi, C., Emerging materials and processes for thermal barrier systems, Curr. Opin. Solid State Mater. Sci., 2004, vol. 8, pp. 77–91.

Cao, X.Q., Vassen, R., and Stoever, D., Ceramic materials for thermal barrier coatings, J. Eur. Ceram. Soc., 2004, vol. 24, no. 1, pp. 1–10.

Evans, A.G., Clarke, D.R., and Levi, C.G., The influence of oxides on the performance of advanced gas turbines, J. Eur. Ceram. Soc., 2008, vol. 28, pp. 1405–1419.

Cao, X.Q., Application of rare earths in thermal barrier coating materials, J. Mater. Sci. Technol, 2007, vol. 23, no. 1, pp. 15–35.

Liu, H.S., Li, Q., Li, Y., et al., Microstructure, phase stability and thermal conductivity of plasma sprayed Yb2O3, Y2O3 co-stabilized ZrO2 coatings, Solid State Sci., 2011, vol. 13, no. 3, pp. 513–519.

Curry, N., Markocsan, N., Ostergren, L., Li, X., and Dorfman, M., Evaluation of the lifetime and thermal conductivity of dysprosia-stabilized thermal barrier coating systems, J. Therm. Spray Technol., 2013, vol. 22, no. 6, pp. 864–872.

Gupta, M., Curry, N., Nylen, P., Markocsan, N., and Vassen, R., Design of next generation thermal barrier coatings—experiments and modeling, Surf. Coat. Technol., 2013, vol. 220, pp. 20–26.

Nicholls, J.R., Lawson, K.J., Johnstone, A., and Rickerby, D.S., Methods to reduce the thermal conductivity of EB-PVD TBCs, Surf. Coat. Technol., 2002, vols. 151–152, pp. 383–391.

Zhu, D. and Miller, R., Development of advanced low conductivity thermal barrier coatings, Int. J. Appl. Ceram. Technol., 2004, vol. 1, no. 1, pp. 86–94.

Tritt, T., Thermal Conductivity: Theory, Properties, and Applications, New York: Kluwer, 2004.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.V. Mazilin, L.Kh. Baldaev, D.V. Drobot, E.Yu. Marchukov, N.G. Zaitsev, 2016, published in Neorganicheskie Materialy, 2016, Vol. 52, No. 8, pp. 865–873.

Rights and permissions

About this article

Cite this article

Mazilin, I.V., Baldaev, L.K., Drobot, D.V. et al. Phase composition and thermal conductivity of zirconia-based thermal barrier coatings. Inorg Mater 52, 802–810 (2016). https://doi.org/10.1134/S0020168516080124

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168516080124