Abstract

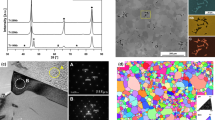

Ti-Al intermetallics have been produced using mechanical alloying technique. A composition of Ti-48Al-2Nb at % powders was mechanically alloyed for various durations of 20, 40, 60, 80 and 100 h. At the early stages of milling, a Ti (Al) solid solution is formed, on further milling the formation of amorphous phase occurs. Traces of TiAl and Ti3Al were formed with major Ti and Al phases after milling at 40 h and beyond. When further milled, phases of intermetallic compounds like TiAl and Ti3Al were formed after 80 hours of milling and they also found in 100 h milled powders. The powders milled for different durations were sintered at 785°C in vacuum. The mechanically alloyed powders as well as the sintered compacts were characterized by XRD, FESEM and DTA to determine the phases, crystallite size, microstructures and the influence of sintering over mechanical alloying.

Similar content being viewed by others

References

Chen, G., Zhang, W., Wang, Y., Wang, G., and Sun, Z., in Structural Intermetallics, Darolia, R., Lewandowski, J.J., Liu, C.T., Martin, P.L., Miracle, D.B., and Nathal, M.V., Eds., Warrendale, Pennsylvania, United States: TMS, 1993, p. 319.

Chen, G., Zhang, W., Liu, Z., Li, S., and Kim, Y.W., in Gamma Titanium Aluminides, Kim, Y.W., Dimiduk, D.M., and Loretto, M.H., Eds., Warrendale, Pennsylvania, United States: TMS, 1999, p. 371.

Chen, G. and Zhang, L., Mater. Sci. Eng., A, 2002, vols. 329–331, p. 163.

Yan, Y.Q., Zhang, Z.Q., Zhen, Z.G., Wang, K.G., and Zhou, L., Mater. Sci. Eng., A, 2000, vol. 280, p. 187.

Fan, G.J., Quan, M.X., and Hu, Z.Q., J. Mater. Sci., 1995, vol. 30, p. 4847.

Wenbin, F., Lianxi, H., Wenxiong, H., Erde, W., and Xiaoqing, L., Mater. Sci. Eng., A, 2005, vol. 403, p. 186.

Hashimoto, K., Kimura, M., and Mizuhara, Y., Intermetallics, 1998, vol. 6, p. 667.

Gil, I., Manoz-Morris, M.A., and Morris, D.G., Intermetallics, 2001, vol. 9, p. 377.

Suryanarayana, C., Mechanical Alloying and Milling, New York: Marcel Dekker, 2004.

Suryanarayana, C., Korth, G.E., and Froes, F.H., Metall. Mater. Trans. A, 1997, vol. 28, p. 293.

Liu, Y. and Liu, W., J. Alloys Compd., 2007, vol. 440, p. 154.

Kambara, M., Uenishi, K., and Kobayashi, K.F., J. Mater. Sci., 2000, vol. 35, p. 2897.

Fadeeva, V.I., Leonov, A.V., Szewczak, E., and Matyja, H., Mater. Sci. Eng., A, 1998, vol. 242, p. 230.

Bhattacharya, P., Bellon, P., Averback, R.S., and Hales, S.J., J. Alloys Compd., 2004, vol. 368, p. 187.

Cullity, B.D., Elements of X-Ray Diffraction, Reading, Massachusetts, United States: Addison-Welsey, 1969.

Hay, J.L. and Pharr, G.M., ASM Handbook, Materials Park, Ohio, United States: ASM International, 2000, vol. 3, sect. 2, p. 54.

Dobbins, T., Abrecht, M., Uprety, Y., and Moore, K., Nanotechnology, 2009, vol. 20, p. 204014.

Froes, F.H., Suryanarayana, C., Russell, K., and Li, C.-G., Mater. Sci. Eng., A, 1995, vol. 192/193, p. 612.

Zou, J., Fu, C.L., and Yoo, M.H., Intermetallics, vol. 3, p. 265.

Gorbatov, V.I., Polev, V.F., Pilugin, V.P., Korshunov, I.G., Smirnov, A.L., Talutz, S.G., and Brytkov, D.A., High Temp., 2013, vol. 51, no. 4, p. 482.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Mishra, D.D., Agarwala, V. & Agarwala, R.C. Sintering behavior of mechanically alloyed Ti-48Al-2Nb aluminides. High Temp 52, 65–71 (2014). https://doi.org/10.1134/S0018151X14010155

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0018151X14010155