Abstract

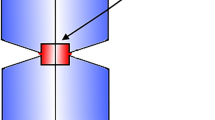

In order to develop the neutron absorbing and shield materials, a hot-rolled 0.02%-Gd duplex stainless steel was prepared with 55 vol. % of ferrite and 45 vol. % of austenite. The σ phase with an average grain size of 9–11 μm in austenitic (γ) grains tended to be elongated parallel to the rolling direction, with (100) poles concentrated towards the normal direction, and (110) poles located between the normal and radial directions (ND and RD, respectively). Most of the gadolinium existed as sub-micro-meter-sized Gd2O3 and GdCrO3 precipitates. The yield strength, ultimate tensile strength, elongation, and microhardness of the 0.02%-Gd duplex stainless steel were 522.8 MPa, 700.2 MPa, 38.1%, and 258.5–314.7 HV, respectively. The friction coefficient and wear resistance were 3.11 and 0.004 mg/kg/cycle, respectively. The corrosion potential and corrosion rate of the 0.02%-Gd duplex stainless steel were–0.448 V SHE and 1.263 × 10–3 A/cm2 for 1M-HCl,–0.544 V SHE and 2.619 × 10–3 A/cm2 for 1M-NaCl,–0.299 V SHE and 1.469 × 10–3 A/cm2 for 1M-H2SO4, and–0.607 V SHE and 2.295 × 10–3 A/cm2 for synthetic water, respectively. The coefficient of neutron transmission for the 0.02%-Gd duplex stainless steel sheet of 2 mm thickness at neutron beam wavelength of 0.48 nm was 0.6.

Similar content being viewed by others

References

R. Machiels and R. Lambert, Handbook on Neutron Absorber Materials for Spent Nuclear Fuel Applications Technical Report RPRI-TR-1019110, Electronic Power Research Inst. USA (2009).

ASTM C750-89, Standard Specifications for Nuclear Grade Boron Carbide Powder (1997).

ASTM A887-89, Standard Specification for Borated Stainless Steel Plate, Sheet, and Strip for Nuclear Application (2004).

H. Shimojo, Taniuchi. K. Kajihara, and Y. Aruga, “Borated aluminum alloy manufacturing technology,” Kobe Steel Eng. Rep. 53(3), 12–17 (2003).

P. Moldavan and G. Popescu, “The grain refinement of 6063 aluminum using Al–5Ti–1B and Al–3Ti–0.15 C grain refiners,” J. Metals, 56(11), 59–61 (2004).

D. C. Halverson, A. J. Pyzik, I. A. Aksay, and W. E. Snowden, “Processing of boron carbide–aluminum composites,” J. Am. Ceram. Soc. 72, 775–790 (1989).

L. Karlson and H. Norden, “Non-equilibrium grain boundary segregation of boron in austenitic stainless steel—II. Fine scale segregation behavior,” Acta Metall. 36, 13–24 (1988).

W. Hurt, G. Wachs, Ch. Robino, R. Mizia, and P. McConnel, “Nickel based gadolinium alloy for neutron adsorption application in RAM packages,” Proc. 15th Int. Symp. on Packaging and Transp. Radiact. Mater. (PATRAM-2007), Miami, Florida (2007).

Z. Khan, “Influence of gadolinium on the microstructure and mechanical properties of steel and stainless steel,” J. Southern African Inst. Mining Metall. 112, 309–322 (2003).

G. W. Wachs, J. W. Sterbentz, L. M. Montierth, F. K. Tovesson, and T. S. Hill, Characterization of an Advanced Gadolinium Neutron Absorber Alloy by Means of Neutron Transmission INL/CON-07-12838, Idaho Nat. Lab. (2007).

Y. Choi, B. M. Moon, and D. S. Shon, “Fabrication of Gd containing duplex stainless steel sheet for neutron absorbing structural materials,” Nucl. Eng. Technol. 45, 689–694 (2013).

Y. S. Sato and H. Kokawa, “Preferential precipitation site of sigma phase in duplex stainless steel weld metal,” Scr. Mater. 40, 659–663 (1999).

B. M. Moon, J. H. Ahn, and S. T. Kim, “A duplex stainless steel casting with 0.1 wt. % gadolinium for a neutron absorbing material with high strength and corrosion resistance,” Proc. 71st World Foundry Congress (WFC 2014), Bilbao, Spain, 19–21 May, 2014, Vol. 1, pp. 445–449.

L. A. Norstrom, “On the yield strength of quenched low-carbon lath martensite,” Scand. J. Metall. 5(4), 159–165 (1976).

H. Okamoto, “Fe–Gd (Iron–Gadolinium) phase diagram,” J. Phase Equilib. 18(1), 109–111 (1997).

K. Ravindranath and S. N. Malhotra, “The influence of aging on the intergranular corrosion of 22 chromium–5 nickel duplex stainless steel,” Corros. Sci. 37(1), 121–132 (1995).

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Baik, Y., Choi, Y., Moon, B.M. et al. Effect of gadolinium addition on the corrosion, wear, and neutron absorbing behaviors of duplex stainless steel sheet. Phys. Metals Metallogr. 116, 1135–1142 (2015). https://doi.org/10.1134/S0031918X15110137

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X15110137