Abstract

Background, Goal and Scope

The palm oil industry is one of the leading industries in Malaysia. With a yearly production of more than 13 million tons of crude palm oil (CPO) and plantations covering 11% of the Malaysian land area it is an industry to be reckoned with, also when it comes to environmental impacts. One way to describe and present the environmental impacts is through a life cycle assessment, LCA. This assessment aims to introduce the concept of LCA and perform a screening LCA on crude palm oil production in Malaysia including the stages of plantation, transport and milling. The assessment is largely based on general data and is thus meant to function as an indication of the environmental threads posed by CPO production and as a guideline to CPO producers and local universities on how to perform an LCA on a palm oil scenario. Due to the general data background the results of this report should not be quoted directly for decision making. The Functional Unit, to which all masses and emissions in this assessment have been adjusted, is the production of 1000 kg of CPO in Malaysia.

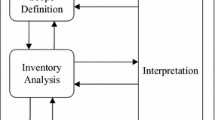

Method

Initially an overview of palm oil production was obtained and the outlines and borders of the assessment were determined along with the specific goal and scope of the assessment. The data for the assessment was collected from three different sources:

-

1. Earlier studies and statistics on palm oil production in Malaysia

-

2. Studies on similar processes, when palm oil related processes were not available

-

3. General data from the SimaPro 5 database

-

The European Eco-Indicator 99 method and European databases included in the LCA software SimaPro 5 have been used for the impact calculations.

Results and Discussion

The impact processes related to the plantation are the on-site energy use (mainly diesel) and the production of artificial fertilizer. Pesticide use contributes a minor impact due to widely used integrated biological poet management. For transportation the only impact is from combustion of diesel and at the mill the boiler is the sole significant contributor – positively through electricity production and negatively by emissions from the boiler. Impacts from POME (Palm Oil Mill Effluent) are not dealt with in the main assessment, but touched upon in alternative scenarios. The results clearly show that fertilizer production is the most polluting process in the system followed by transportation and the boiler emissions at a tie. The most significant impacts from the system are respiratory inorganics and depletion of fossil fuels, of which the boiler emission is the main responsible for the prior and fertilizer production and transportation are responsible for the latter. It is also evident from the results that crude palm oil production is a significant environmental impact generator in Malaysia due to the vast production quantities. Alternative scenarios revealed that there are significant impact savings to be made by introduction of environmental investments, both regarding the overall impacts and in particularly regarding CO2 emissions.

Conclusion

A screening LCA was successfully conducted on the Malaysian crude palm oil production thus promising potentials for the palm oil industry to conduct their own inventories and assessments using specific company data. Crude palm oil production in Malaysia is responsible for app. 3.5% of the total environmental impacts in the country and must thus be given attention to reduce impacts. Alternatives such as optimized use of organic fertilizer, environmentally friendlier artificial fertilizer production, rail transport, approved filters at the mill boiler stack and biogas harvest from POME digestion must thus be promoted in the industry.

Recommendation

. The Malaysian palm oil industry should take steps towards introducing LCA. Exhaustive inventories are likely to open the eyes of many companies towards implementing environmental investments and improve the international competitiveness. In order to retrieve results with a greater accuracy in the future, databases must be created containing life cycle data from Malaysian scenarios and normalization and weighting factors must be designed to reflect Malaysian conditions. The Malaysian authorities must create incentives through increased tariffs on electricity and diesel and/or financial support for cleaner technology investments.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hansen, S. Feasibility Study of Performing an Life Cycle Assessment on Crude Palm Oil Production in Malaysia (9 pp). Int J Life Cycle Assessment 12, 50–58 (2007). https://doi.org/10.1065/lca2005.08.226

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1065/lca2005.08.226