Abstract

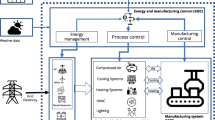

There is currently considerable debate concerning increasing energy prices. For Swedish industry electricity prices have increased rapidly during the last 6 years, roughly doubling the cost. This situation has been the catalyst for significant increases in energy research and the research work presented in this paper is part of this growing body. The paper reports an approach to analyse and reduce energy use within energy-intensive industry, whereby a Swedish iron foundry is used as a test case. The results show that by using a customized simulation model a company can lower its overall energy costs through improved planning of the production process. The method formulated enables the disaggregating of energy parameters into groupings and provides examples of how the simulation model can be realized in order to account for energy usage. Different aspects of energy and power usage as well as the corresponding costs are analysed.

Similar content being viewed by others

References

Banks J, Carson JS, Nelson BL and Nicol DM (2005). Discrete-Event System Simulation, 4th edn. Prentice-Hall International Series in Industrial and Systems Engineering: Upper Saddle River, USA.

BrooksSoftware (2006). www.brookssoftware.com, accessed 29 April 2007.

COM (European Commission) (2006). Directive 2006/32/EC of the European Parliament and of the Council of 5 April 2006 on Energy End-Use Efficiency and Energy Services and Repealing Council Directive 93/76/EEC. European Commission: Brussels.

DETR (Department of the Environment, Transport and the Regions) (1999). Achieving high yields in iron foundries. Good practice guide 17. DETR: Harwell, UK.

EEPO (European Electricity Prices Observatory) (2003). Year 2002 Results. INRA(I.C.O.): Brussels, Belgium.

Hitomi K (1996). Manufacturing Systems Engineering—A Unified Approach to Manufacturing Technology, Production Management and Industrial Economics, 2nd edn. Taylor & Francis: London, UK.

Jägstam M and Oscarsson J (2003). Method Handbook—Industrial Production Simulation, Version 1.0. Department of Engineering Science, University of Skövde: Sweden.

Law AM (2007) Simulation Modeling and Analysis, 4th edn. McGraw-Hill Series in Industrial Engineering and Management Science, McGraw-Hill, Inc: New York, USA.

Musselman K (1994). Guidelines for simulation project success. In: Proceedings of the 1994 Winter Simulation Conference, IEEE: Orlando, Florida, USA.

NordPool (2007). Elspot Monthly Prices (online) Available via www.nordpoolspot.com/trading/The_Elspot_market, accessed 14 April 2007.

OECD (Organization for Economic Cooperation and Development) (2004). OECD Key Environmental Indicators Paris, France (online). Available via www.oecd.org/dataoecd/32/20/31558547.pdf, accessed 20 May 2007.

Pegden CD, Shannon RE and Sadowski RP (1995). Introduction to Simulation Using SIMAN, 2nd edn. McGraw-Hill, Inc: New York, USA.

Pidd M (2004). Computer Simulation in Management Science, 5th edn. John Wiley & Sons, Ltd: Chichester, England.

Robinson S (1994). Successful Simulation: A Practical Approach to Simulation Projects. McGraw-Hill Book Company Europe: Berkshire, England.

Rohdin P and Thollander P (2006a). Barriers to and driving forces for energy efficiency in the non-energy intensive manufacturing industry in Sweden. Energy 31 (12): 1836–1844.

Rohdin P and Thollander P (2006b). Synen på energieffektivisering, produktionssimulering, energianalyser och styrmedel—en studie av nio svenska gjuterier. Linköpings Universitet: Swedish, Working Paper.

Rohdin P, Thollander P and Solding P (2007). Barriers to and drivers for energy efficiency in the Swedish foundry industry. Energ Policy 35 (1): 672–677.

SCB (Statistiska Centralbyrån) (2007). Statistics from SCB (online). Available via www.scb.se, accessed 25 April 2007.

SEA (Swedish Energy Agency) (2007). Energy in Sweden 2007, Report nr: ET2007: 51. Energimyndighetens förlag (online). Available via www.swedishenergyagency.se/web/biblshop.nsf, accessed 11 August 2008.

Solding P (2008). More energy efficient casting without loss of output. In: Proceedings of the 68th World Foundry Congress 2008, WFO: Chennai, India.

Solding P and Petku D (2005). Applying energy aspects on simulation of energy-intensive production systems. In: Proceedings of the 2005 Winter Simulation Conference, IEEE: Orlando, USA.

Solding P and Thollander P (2006). Increased energy efficiency in a Swedish iron foundry through use of discrete event simulation. In: Proceedings of the 2006 Winter Simulation Conference, IEEE: Monterey, USA.

Swerea SWECAST (2007). 2006—ett nytt rekordår för de svenska gjuterierna—Gjuteribranschen fortsatt het (online) Available via http://www.gjuteriforeningen.se/aktuellt/pressrelease0703.pdf, accessed 8 June 2008 (in Swedish).

Thollander P, Karlsson M, Söderström M and Creutz D (2005). Reducing industrial energy costs through energy efficiency measures in a liberalized European electricity market—Case study of a Swedish iron foundry. Appl Energ 81 (2): 115–126.

Trygg L and Karlsson BG (2005). Industrial DSM in a deregulated European electricity market—a case study of 11 plants in Sweden. Energy Policy 33 (11): 1445–1459.

Acknowledgements

We thank AB Bruzaholms Bruk for letting us undertake work within their facility and for their assistance during the period. We also thank the Swedish Energy Agency for their sponsorship of this project.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Solding, P., Thollander, P. & Moore, P. Improved energy-efficient production using discrete event simulation. J Simulation 3, 191–201 (2009). https://doi.org/10.1057/jos.2008.26

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1057/jos.2008.26