Abstract

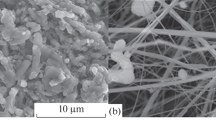

The results of Vickers microhardness and high-velocity impact tests on monolithic ZrB2/SiC and HfB2/SiC ultra-high temperature ceramic (UHTC) composites are presented. The UHTC materials exhibit fracture behavior typical of ceramics under indentation and impact loading. The materials are relatively hard with microhardness values of about 15 to 20 GPa. Cracks were observed to extend from the corners of indentations. Impacts of stainless steel and tungsten carbide spheres, with diameters in the 500 to 800 micron range and velocities of 200 to 300 m/s, produced minimal plastic deformation but significant radial and ring cracking at the impact sites. Impacts of micron-scale iron particles traveling at 1 to 3 km/s produced essentially no surface damage.

Similar content being viewed by others

References

D. SAUNDERS, G. ALLEN, P. GAGE and J. REUTHER, “Crew Transfer Vehicle Trajectory Optimization,” AIAA Paper 2001-2885, June 2001.

J. REUTHER, D. KINNEY, S. SMITH, D. KONTINOS, P. GAGE and D. SAUNDERS, “A Reusable Space Vehicle Design Study Exploring Sharp Leading Edges,” AIAA Paper 2001-2884, June 2001.

K. UPADHYA, J.-M. YANG and W. P. HOFFMAN, The Amer. Ceram. Soc. Bull. 76 (1997) 51.

L. KAUFMAN, “Boride Composites—A New Generation of Nose Cap and Leading Edge Materials for Reusable Lifting Re-entry Systems,” AIAA Paper 70-278, Feb. 1970.

E. V. CLOUGHERTY, R. L. POBER and L. KAUFMAN, Trans. Metall. Soc. AIME 242 (1968) 1077.

W. C. TRIPP, H. H. DAVIS and H. C. GRAHAM, Ceram. Bull. 52 (1973) 612.

J. BULL. in 19th Conference on Composite Materials and Structures 157 (CIAC, Cocoa Beach, FL, 1995).

A. G. METCALFE, N. B. ELSNER, D. T. ALLEN, E. WUCHINA, M. OPEKA and E. OPILA, Electrochem. Soc. Proc. 99(38) (1999) 489.

I. G. TALMY, J. A. ZAYKOSKI and M. A. OPEKA, Ceram. Engng. Sci. Proc. 19 (1998) 104.

P. KOLODZIEJ, J. BULL, J. SALUTE and D. L. KEESE, “First Flight Demonstration of a Sharp Ultra-High Temperature Ceramic Nosetip,” NASA TM-112215, Dec. 1997.

J. BULL, P. KOLODZIEJ, J. SALUTE and D. KEESE, “Design, Instrumentation and Preflight Testing of a Sharp Ultra-High Temperature Ceramic Nosetip,” NASA TM-1998-112229, Oct. 1998.

T. KOBAYASHI and D. A. SHOCKEY, Adv. Mater. Proc. 140 (1991) 28.

ANON, “Standard Test Method for Monotonic Equibiaxial Flexural Strength of Advanced Ceramics at Ambient Temperature,” ASTM C 1499-03, July 2003.

B. LAWN and R. WILSHAW, J. Mater. Sci. 10 (1975) 1049.

A. G. EVANS and T. R. WILSHAW, Acta Metall. 24 (1976) 939.

D. R. CLARKE and K. T. FABER, J. Phys. Chem. Solids 48 (1987) 1115.

B. R. LAWN and M. V. SWAIN, J. Mater. Sci. 10 (1975) 113.

B. R. LAWN, T. JENSEN and A. ARORA, J. Mater. Sci. Lett. 11 (1976) 573.

B. R. LAWN and E. R. FULLER, J. Mater. Sci. 10 (1975) 2016.

A. G. EVANS, J. Amer. Ceram. Soc. 56 (1973) 405.

B. R. LAWN, S. M. WIEDERHORN and H. H. JOHNSON, ibid. 58 (1975) 428.

C. G. KNIGHT, M. V. SWAIN and M. M. CHAUDHRI, J. Mater. Sci. 12 (1977) 1573.

S. M. WIEDERHORN and B. R. LAWN, J. Amer. Ceram. Soc. 60 (1977) 451.

W. H. RHODES, E. V. CLOUGHERTY and D. KALISH, “Research and Development of Refractory Oxidation-Resistant Diborides, Part II, Vol. IV: Mechanical Properties,” AFML-TR-68-190 Jan. 1970.

V. E. LYSAGHT and A. DEBELLIS, “Hardness Testing Handbook” (American Chain and Cable Company, 1969).

Y. V. MILMAN, B. A. GALANOV and S. I. CHUGUNOVA, Acta Metallurgica et Materialia 41 (1993) 2523.

L. BSENKO and T. LUNDSTRÖM, J. Less-Comm. Met. 34 (1974) 273.

K. NAKANO, H. MATSUBARA and T. IMURA, ibid. 47 (1976) 259.

V. M. GLAZOV and V. N. VIGDOROVICH, “Microhardness of Metals and Semiconductors” (Consultants Bureau, New York, 1971).

G. D. QUINN, P. J. PATEL and I. LLOYD, J. Res. National Inst. Stand. Techn. 107 (2002) 299.

A. KAKANAKOVA-GEORGIEVA, E. P. TRIFONOVA, R. YAKIMOVA, M. F. MACMILLAN and E. JANZÉN, Cryst. Res. Techn. 34 (1999) 943.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Marschall, J., Erlich, D.C., Manning, H. et al. Microhardness and high-velocity impact resistance of HfB2/SiC and ZrB2/SiC composites. Journal of Materials Science 39, 5959–5968 (2004). https://doi.org/10.1023/B:JMSC.0000041692.72915.e8

Issue Date:

DOI: https://doi.org/10.1023/B:JMSC.0000041692.72915.e8