Abstract

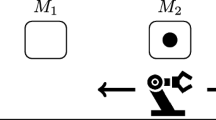

A robotic cell is a manufacturing system that is widely used in industry. A robotic cell contains two or more robot-served machines, repetitively producing a family of similar parts, in a steady state. There are no buffers at or between the machines. Both the robot move cycle and the sequence of parts to produce are chosen in order to minimize the cycle time needed to produce a given set of parts. This objective is also equivalent to throughput rate maximization. In practice, simple robot move cycles that produce one unit are preferred by industry. In an m machine cell for m >= 2, there are m! such cycles that are potentially optimal. Choosing any one of these cycles reduces the cycle time minimization problem to a unique part sequencing problem. We prove the following results in an m machine cell, for any m >= 2. The part sequencing problems associated with these robot move cycles are classified into the following categories: (i) sequence independent; (ii) capable of formulation as a traveling salesman problem (TSP), but polynomially solvable; (iii) capable of formulation as a TSP and unary NP-hard; and (iv) unary NP-hard, but not having TSP structure. As a consequence of this classification, we prove that the part sequencing problems associated with exactly 2m-2 of the m! available robot cycles are polynomially solvable. The remaining cycles have associated part sequencing problems which are unary NP-hard.

Similar content being viewed by others

References

C.R. Asfahl, Robots and Manufacturing Automation, Wiley, New York, 1985.

N. Brauner and G. Finke, On the conjecture in robotic cells: New simplified proof for the three-machine case, Research Report RR971-I, Laboratoire LEIBNIZ, Institut IMAG, Grenoble, France 1997.

J.L. Cheng, H. Kise and Y. Karuno, Optimal scheduling for an automated m-machine flowshop, Journal of the Operations Research Society of Japan 40(1997)356 - 372.

Y. Crama, Combinatorial optimization models for production scheduling in automated manufacturing systems, European Journal of Operational Research 99(1997)136 -153.

Y. Crama and J. van de Klundert, Cyclic scheduling of identical parts in a robotic cell, Operations Research, 1998, to appear.

T. Ganesharajah, N.G. Hall and C. Sriskandarajah, Design and operational issues in AGV-served manufacturing systems, Annals of Operations Research, 1998, this volume.

M.R. Garey and D.S. Johnson, Computers and Intractability: A Guide to the Theory of NPCompleteness, W.H. Freeman, San Francisco, 1979.

M. Gendreau, A. Hertz and G. Laporte, New insertion and postoptimization procedures for the traveling salesman problem, Operations Research 40(1992)1086 - 1094.

P.C. Gilmore and R.E. Gomory, Scheduling a one-state variable machine: A solvable case of the traveling salesman problem, Operations Research 12(1964)655 - 679.

R.L. Graham, E.L. Lawler, J.K. Lenstra and A.H.G. Rinnooy Kan, Optimization and approximation in deterministic sequencing and scheduling: A survey, Annals of Discrete Mathematics 5(1979) 287 - 326.

M.P. Groover, Automation, Production Systems, and Computer-Integrated Manufacturing, Prentice-Hall, Englewood Cliffs, NJ, 1987.

N.G. Hall, Operations research techniques for robotic system design, planning, control and analysis, in: Handbook of Industrial Robotics, Vol. 2, ed. S.Y. Nof, Wiley, 1999, to appear.

N.G. Hall, H. Kamoun and C. Sriskandarajah, Scheduling in robotic cells: Classification, two and three machine cells, Operations Research 45(1997)421 - 439.

N.G. Hall, H. Kamoun and C. Sriskandarajah, Scheduling in robotic cells: Complexity and steady state analysis, European Journal of Operational Research, 1998, to appear.

N.G. Hall, T.-E. Lee and M.E. Posner, Periodic shop scheduling problems, Working Paper, Fisher College of Business, The Ohio State University, 1997.

N.G. Hall, C.N. Potts and C. Sriskandarajah, Parallel machine scheduling with a common server, Working Paper, Fisher College of Business, The Ohio State University, 1997.

N.G. Hall and C. Sriskandarajah, A survey of machine scheduling problems with blocking and no-wait in process, Operations Research 44(1996)510 - 525.

J. Hartley, Robots at Work: A Practical Guide for Engineers and Managers, IFS Ltd., UK, 1983.

A. Hertz, Y. Mottet and Y. Rochat, On a scheduling problem in robotized analytical system, Working Paper ORWP 92/17, Ecole Polytechnique Federale, Lausanne, 1992.

H. Kamoun, N.G. Hall and C. Sriskandarajah, Scheduling in robotic cells: Heuristics and cell design, revision submitted to Operations Research; also, Working Paper, Fisher College of Business, The Ohio State University, 1997.

V.B. Kats and Z.N. Mikhailetsky, Exact solution of cyclic scheduling problem, Automation and Remote Control 4(1980)187 - 190 (in Russian).

H. Kise, T. Shioyama and T. Ibaraki, Automated two-machine flowshop scheduling: A solvable case, IIE Transactions 23, no.1(1991)10 - 16.

E.L. Lawler, J.K. Lenstra, A.H.G. Rinnooy Kan and D.B. Shmoys, The Traveling Salesman Problem: A Guided Tour of Combinatorial Optimization, Wiley, Chichester, UK, 1985.

T.-E. Lee and M.E. Posner, Performance measures and schedules in periodic job shops, Operations Research 45(1997)72 -91.

L. Lei and T.-J. Wang, A proof on the NP-completeness of the hoist scheduling problems, GSM Working Paper 89/16, Rutgers University, 1989.

L. Lei and T.-J. Wang, Determining optimal cyclic hoist schedules in a single-hoist electroplating line, IIE Transactions 26, no.2(1994)25 - 33.

E. Levner, V. Kats and V.E. Levit, An improved algorithm for cyclic robotic flowshop scheduling in a robotic cell, European Journal of Operational Research 97(1997)500 - 508.

E.M. Livshits, Z.N. Mikhailetsky and E.V. Chervyakov, A scheduling problem in an automated flow line with an automated operator, Computational Mathematics and Computerized Systems 5 (1974)151 - 155 (in Russian).

R. Logendran and C. Sriskandarajah, Sequencing of robot activities and parts in two machine robotic cells, International Journal of Production Research 34(1996)3447 - 3463.

V.S. Mikhalevich, S.A. Beletsky and A.P. Monastyrev, Optimization of multi-stage cyclic service of production line by a transmanipulator, Cybernetics 24(1988)500 - 511.

R.K. Miller and T.C. Walker, FMS/CIM Systems Integration Handbook, The Fairmont Press, Lilburn, GA, 1990.

L.W. Phillips and P.S. Unger, Mathematical programming solution of hoist scheduling problem, AIIE Transactions 8(1976)219 - 225.

H. Röck, The three machine no-wait flowshop problem is NP-complete, Journal of the Association for Computing Machinery 31(1984)336 - 345.

S.P. Sethi, C. Sriskandarajah, G. Sorger, J. Blazewicz and W. Kubiak, Sequencing of parts and robot moves in a robotic cell, International Journal of Flexible Manufacturing Systems 4(1992) 331 - 358.

G.W. Shapiro and H.W. Nuttle, Hoist scheduling for a PCB electroplating facility, IIE Transactions 20(1988)157 - 167.

W. Song, Z.B. Zabinsky and R.L. Storch, An algorithm for scheduling a chemical processing tank line, Production Planning and Control 4(1993)323 - 332.

J. van de Klundert, Scheduling problems in automated manufacturing, Ph.D. Dissertation No. 96-35, Faculty of Economics and Business Administration, University of Limburg, Maastricht, The Netherlands, 1996.

R.J. Wittrock, Scheduling algorithms for flexible flow lines, IBM Journal of Research and Development 29(1985)401- 412.

Rights and permissions

About this article

Cite this article

Sriskandarajah, C., Hall, N.G. & Kamoun, H. Scheduling large robotic cells without buffers. Annals of Operations Research 76, 287–321 (1998). https://doi.org/10.1023/A:1018952722784

Issue Date:

DOI: https://doi.org/10.1023/A:1018952722784