Abstract

The corrosion behavior of particulate reinforced graphite/copper (Grp/Cu) metal matrix composites (MMCs) was studied in 3.5 wt.% solution using electrochemical techniques, ionic solution analysis, scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDX), and X-ray diffraction (XRD) techniques. The materials under investigation were high energy–high rate (HEHR) consolidated Grp/Cu metal matrix composites. HEHR processing employs a 10 MJ homopolar generator that supplies a 100 kA pulse to rapidly heat and solidify the composite powder compact. This short time at high temperature and the preferential heating and melting at the graphite-copper interface serve to encapsulate the graphite reinforcement, thus providing a highly densified composite product.

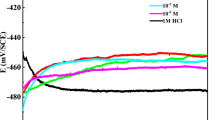

Initially the open circuit potential corrosion behavior of 1.2, 5, 15, 25, and 40 volume percent Gr_pCu composites was studied in aerated and deaerated 3.5 wt.% NaCl solution using SEM and EDX. Subsequently, the environmental stability of these composites was studied using electrochemical techniques such as polarization resistance and potentiodynamic polarization. The severity of corrosive attack increased with increasing graphite content and in aerated solutions. In addition, solutions from these tests were analyzed to determine the relative amounts of copper and carbon present in the electrolyte after polarization tests. Microscopic analysis techniques were used to characterize the corrosion morphologies and the extensive localized corrosion occurring at the graphite-copper interface. The effectiveness of benzotriazole as a corrosion inhibitor for the copper MMCs was also studied.

Similar content being viewed by others

References

Ellis, D. L. and McDaniels, D. L., Thermal Conductivity and Thermal Expansion of Graphite Fiber/Copper Matrix Composites, NASA Technical Memorandum, NASA/TM-105233, NASA Lewis Research Center, Cleveland, OH, September 1990, 1–17.

Metals Handbook, Ninth edition, 13, ASM International, Metals Park, OH, 1987.

Tuthill, A. H., ‘Guidelines for the Use of Copper Alloys in Seawater’, Materials Performance 26, 1987, 12–22.

Nystrom, W. A., ‘Copper in Sliding Electrical Contacts’, in Pierre Taubenbalt (ed.), Copper Base Powder Metallurgy, Metal Powder Industries Federation Publishers, Princeton, New Jersey, 1980, 135–145.

Marcus, H. L., Weldon, W. F. and Persad, C., Technical Report Contract No. N62269–85-C0222 (The University of Texas at Austin, Austin, TX, February 10, 1987).

Owen, K. C., Wang, M. J., Persad, C. and Eliezer, Z., ‘Preparation and Tribological Evaluation of Copper-Graphite Composites by High Energy-High Rate Powder Consolidation’, Wear 120, 1987, 117–121.

Aylor, D. M., Development of Copper Base Metal Matrix Composites, Report No. DTNSRDC/SME–85-10, David Taylor Naval Ship R&D Center, Bethesda, MD, March, 1985.

McDanels, D. L. and Diaz, J. O., Exploratory Feasibility Studies of Graphite Fiber Reinforced Copper Matrix Composites for Space Power Radiator Panels, NASA Technical Memorandum, NASA TM-102328, NASA Lewis Research Center, Cleveland, OH, September, 1989, 1–20.

North, R. F. and Pryor, M. J., ‘The Influence of Corrosion Product Structure on the Corrosion Rate of Cu-Ni Alloys’, Corrosion Science 10, 1970, 297–311.

Fontana, M. G., Corrosion Engineering, Third Edition, McGraw-Hill, New York, NY, 1988.

Lewis, G., ‘Adsorption Isotherm for the Copper-Benzotriazole System’, British Corrosion Journal 16, 1981, 169–171.

Notoya, T. and Polling, G. W., ‘Topographies of Thick Cu-Benzotriazolate Films on Copper’, Corrosion 32, 1976, 216–223.

Notoya, T. and Polling, G. W., ‘Protection of Copper by Pretreatment with Benzotriazole’, Corrosion 35, 1979, 193–200.

Personal Communication, Bob Carnes, Center for Electromagnetics at The University of Texas at Austin.

Marcus, H. L., Bourell, D. L., Eleizer, Z., Persad, C. and Weldon, W. F., Journal of Metals 39, 1987, 6–10.

Marcus, H. L., Rabenberg, L. K., Persad, C. and Elkabir, G., ‘Microstructural Evaluation of a High Energy-High Rate P/M Processed Aluminum Alloy’, Scripta Metallurgica 20, 1986, 1411–1416.

Lee, H. P. and Nobe, K., ‘Kinetics and Mechanisms of Cu Electrodissolution in Chloride Media’, J. Electrochemical Soc. 133, 1986, 2035–2043.

Milosev, I. and Metikos-Hukovic, M., ‘Passive Films on 90Cu-10Ni Alloy: The Mechanism of Breakdown in Chloride Containing Solutions’, J. Electrochem. Soc. 138, 1991, 61–67.

Sun, H., Orth, J. E. and Wheat, H. G., ‘Corrosion Behavior of Copper-Based Metal Matrix Composites’, Journal of Metals 45, 1993, 36–41.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Orth, J.E., Wheat, H.G. Corrosion Behavior of High Energy–High Rate Consolidated Graphite/Copper Metal Matrix Composites in Chloride Media. Applied Composite Materials 4, 305–320 (1997). https://doi.org/10.1023/A:1008847619254

Issue Date:

DOI: https://doi.org/10.1023/A:1008847619254