Abstract

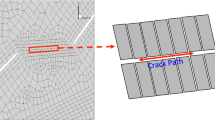

The force resisting the opening of a crack in a brittle matrix composite that is bridged by ductile fibers was studied (Acta Mater. 46(18) (1998) 6381; Acta Mater. 45(9) (1997) 3609). to gain a generic understanding of the crack-bridging process by ductile reinforcements. The matrix was alumina, initially containing a parallel array of fine cylindrical holes. Molten Al was cast into the holes to produce the fibers in situ. A crack was gently introduced to traverse the specimen. The matrix halves were pulled apart in a controlled manner to open the crack. The resisting force increased proportionally to the crack opening over a wide range until a force plateau was reached. Thereafter the force diminished very gradually until failure intervened. Analysis of this counter-intuitive behavior indicated that the excellent adhesion between the fiber and the matrix in combination with the large thermal expansion mismatch must have led to extensive but spotty debonding already from the start of the start of the crack opening. In spite of the well-known ductility of the fibers, the bridging showed quasi-elastic behavior over much of the crack opening. Necking appeared to be suppressed until the separation approached failure. Detailed modeling is offered to provide interpretation of this observed behavior.

Similar content being viewed by others

References

O. Raddatz, G.A. Schneider and N. Claussen, Acta Mater. 46(18) (1998) 6381.

J. Bowling and G.W. Groves, J. Mater. Sci. 14 (1979) 431.

L.S. Sigl,P.A. Mataga,B.J. Dalgleish,R.M. McMeeking and A.G. EVANS, Acta Metall. 36(4) (1988) 945.

P.A. Mataga, ibid. 37(12) (1989) 3349.

M.F. Ashby, F.J. Blunt and M. Bannister, ibid. 37(7) (1989) 1847.

H.E. Deve and M.J. Maloney, ibid. 39(10) (1991) 2275.

M. Bannister and M.F. Ashby, ibid. 39(11) (1991) 2575.

B. Bao and F. Zok, ibid. 41(12) (1993) 3515.

B.D. Flinn, C.S. Lo, W. Zok and A.G. Evans, J. Amer. Ceram. Soc. 76(2) (1993) 369.

M. Hoffman, B. Fiedler, T. Emmel, H. Prielipp, N. Claussen, D. Gross and J. Roedel, Acta Mater. 45(9) (1997) 3609.

M. Hoffman, S. Skirl, W. Pompe and J. Roedel, ibid. 47(2) (1999) 565.

O. Raddatz, G.A. Schneider, W. Maclems, H. Voss and N. Claussen, J. Europ. Ceram. Soc., submitted.

M. Hoffman, S. Skirl, W. Pompe and J. Roedel, Acta Mater. 47(2) (1999) 565.

H.L. Cox, British J. Appl. Phys. 3 (1952) 72.

M.R. Piggott, “Load Bearing Fibre Composites” (Pergamon Press, Oxford, 1980) p. 83ff.

K.K. Chawla, “Composite Materials” (Springer-Verlag, New York, 1987) p. 196ff.

C.-H. Hsueh, J. Mater. Sci. 29 (1994) 5135.

P.W. Bridgman, “Studies in Large Plastic Flowand Fracture” (Mc-Graw Hill, New York, 1952) p. 9ff.

S. Skirl, M. Hoffman, K. Bowman, S. Wiederhorn and J. Roedel, Acta Mater. 46(7) (1998) 2493.

W.S. Kreher, private communication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hillig, W.B., Raddatz, O., Schneider, G.A. et al. Analysis and model of the crack bridging mechanisms in a ductile fiber reinforced ceramic matrix composite. Journal of Materials Science 36, 1653–1663 (2001). https://doi.org/10.1023/A:1017535519524

Issue Date:

DOI: https://doi.org/10.1023/A:1017535519524