Abstract

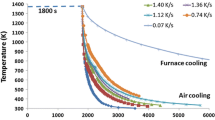

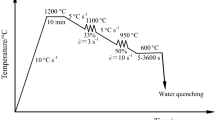

Three steels containing 0.05%C-0.1%V-0.01%N (steel V-LN), 0.05%C-0.1%V-0.02%N (steel V-HN), and 0.05%C-0.1%V-0.02%N-0.01%Ti (steel V-HN-Ti), which were all essentially vanadium microalloyed steels, were subjected to simulating the microstructure of a coarse grained heat affected zone (CGHAZ). The process involved reheating to 1 350 °C, rapid cooling to room temperature, and varying the welding heat input from 15 kJ/cm to 54 kJ/cm, including four cooling rates of t8/5 equal to 7.5 s, 20 s, 40 s, 100 s, and the relationship of heat input to t8/5 was calculated by Quiksim software. The microstructure and precipitation of vanadium and titanium carbon nitrides are studied. The results indicate that the microstructure consists of granular bainite and some side plate ferrite in the grain boundary when the steels are produced with the highest heat input. As the heat input decreased, numerous polygonal ferrites and grain boundary ferrites appeared, and the size apparently increased. When the steel contained high nitrogen, it was considerably easier to form martensite-austenite island, which was even worse for the toughness and other properties of the steel. For the limitation of cooling time, vanadium carbon nitrides could not precipitate sufficiently, but as titanium was added, the unmelted or precipitated TiN on cooling absorbed some fraction of nitrogen in the matrix and made more precipitate positions for the round V(C, N), and thus several useful round particles could be seen in titanium-contained steel, and most of them were around TiN. By this experiment, we can conclude that with the help of titanium, nitrogen-enhanced steel had a better prior austenite grain size, was considerably easier to precipitate, reduced free nitrogen in the matrix effectively, and provided a very effective mechanism for restriction grain growth in the HAZ.

Similar content being viewed by others

References

Hagasaka T, Muroga T, Grossbeck M L, et al. Effects of Post-Weld Heat Treatment Conditions on Hardness, Microstructures and Impact Properties of Vanadium Alloys [J]. Journal of Nuclear Materials, 2002, 307–311: 1595.

Hannerz N E, Jonsson-Holmquist B M. Influence of Vanadium on the Heat-Affected-Zone Properties of Mild Steel [J]. Metal Science, 1974, 8: 228.

Hart P H M, Mitchell P S. The Effect of Vanadium on the Toughness of Welds in Structural and Pipeline Steels. Weld, 1995, 74(7): 239.

LI Y, Crowther D N, Green M J W, et al. The Effect of Vanadium and Niobium on the Properties and Microstructure of the Intercritically Reheated Coarse Grained Heat Affected Zone in Low Carbon Microalloyed Steels [J]. ISIJ International, 2001, 41(1): 46.

LIAO F C, LIU S, Olson D L. Weldability of Nitrogen-Enhanced HSLA Steels [A]. ASME, eds. Proceedings of the 12th International Conference on Offshore Mechanics and Arctic Engineering [C]. Glasgow: ASME, 1993. 231.

Hamada M, Fukada Y, Komizo Y. Microstructure and Precipitation Behavior in Heat Affected Zone of C-Mn Microalloyed Steel Containing Nb, V and Ti [J]. ISIJ International, 1995, 35(10): 1196.

El-Fawakhry K A, Mekkawy M F, Mishreky M L. Characterization of Precipitates in Vanadium and Titanium Microalloyed Steels [J]. ISIJ International, 1991, 31(9): 1020.

YONG Qi-long. Second-Phases in Steel [M]. Beijing: Metallurgical industry press, 2006 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, F., Yong, Ql., Yang, Cf. et al. Microstructure and precipitation behavior in HAZ of V and Ti microalloyed steel. J. Iron Steel Res. Int. 16, 68–72 (2009). https://doi.org/10.1016/S1006-706X(09)60046-7

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(09)60046-7