Abstract

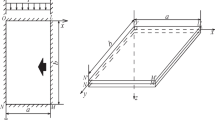

This research investigates roof deformation and failure characteristics, as well as mechanical interaction between the panels of the roof strata above two adjacent working faces in a steeply inclined coal seam. Physical modeling with photogrammetry measurement method has been employed in this investigation. The movement of roof strata and section pillar, as well as the stratum morphological characteristics, was quantitatively analyzed. Results show that the roof movement direction above the two panels has zoning characteristics, especially in the lower panel. Roof migration in the lower panel of the working face is larger than that in the upper panel. The roof to floor closure perpendicular to the seam direction is larger than the sliding along the seam. The maximum roof concave and convex bending occurred at the middle and upper parts of both panels; the roof bending in the upper panel mining area indicates a larger mining disturbance induced by lower panel mining. The void ratio contour of the lower panel is an asymmetrically arched shape, which is different from that of the upper panel area. The higher roof strata above the upper panel exhibit separation and breaking, whereas the lower roof exhibits compression due to mining in lower panel. The section pillar is compressed and slides slightly, which aggravates the mechanical interaction between the panels and increases the caving height of the roof over the lower panel and the periodic weighting intensity.

Similar content being viewed by others

References

Yongping WU, Kongzhi LIU, Dongfeng YUN et al (2014) Research progress on the safe and efficient mining technology of steeply dipping seam [J]. J China Coal Soc 39(8):1611–1618

Kulakov VN (1995) Stress state in the face region of a steep coal bed [J]. J Min Sci 9:161–168

Bodi J (1997) Safety and technological aspects of man less exploitation technology for steep coal seams[C]. In: 27th international conference of safety in mines research institutes, pp 955–965

Singh TN, Gehi LD (1993) State behavior during mining of steeply dipping thick seams-a case study[C]. In: Proceedings of the International Symposium on Thick Seam Mining, pp 311–315

Ladenko AA (1974) Improvements in working steep seams. Int J Rock Mech Min Sci Geomech Abstr 247

Zhou Bangyuan, Wu Yongping, Wu Hourong, et al. 1998 Technology of fully mechanized coal mining in steeply dipping seam[R].Chengdou: Huaying mountain mining bureau, Xi’an: Xi’an Mining & Technology Institute,(in Chinese).

Cheng Wendong, Wang Jun, Yun, Dongfeng.2003 Technology of longwall top coal caving along the Strike in steeply dipping thick coal seam[R]. Lanzhou:Jingyuan Coal Group, Xi’an: Xi’an University of Science and Technology, (in Chinese).

Liu Bin, Wu Yongping, Yun Dongfeng. 2003 Technology of longwall top coal caving along the Strike in steeply dipping thick and inflammable coal seams[R]. Lanzhou:Huating Coal Group, Xi’an: Xi’an University of Science and Technology, (in Chinese).

Xie P (2011) Response of overburden structure and its stability around the longwall mining face area in steeply dipping seam [D]. Xi’an University of Science and Technology, Xi’an (in Chinese)

Xie P, Wu Y, Wang H et al (2012) Study on space activity law of overburden strata above longwall coal mining face in high inclined seam [J]. Coal Sci Techno 40(09):1–5 (in Chinese)

Jiwei Z (2015) The fracture mechanism of main roof stratum and strong mine pressure control method in longwall mining of steeply inclined coal seam in Wang jia-shan Colliery[D]. Beijing University of Science and Technology, Beijing (in Chinese)

Liming L (2015) Research on overburden strata movement law of full-mechanized caving face in Changshanzi steeply dipping coal seam [D]. Xi’an University of Science and Technology, Xi’an (in Chinese)

Jintong Z (2016) Research on reasonable size of coal pillar in steeply dipping seam [D]. Taiyuan University of Technology, Taiyuan (in Chinese)

Wang X (2013) The optimization and research on the reasonable size of coal pillar with fully mechanized caving in large dip angle and thick coal seam [D]. Taiyuan University of Technology, Taiyuan (in Chinese)

Li Long 2014. Coal pillar and surrounding rock structure features in great inclined fully mechanical mining [J]. Shanxi Coal 34(04):24-26(in Chinese).

Hongsheng T, Shihao T, Qingsheng B et al (2013) Instability of a coal pillar section located at a steep mining face: pillar size selection[J]. J China Univ Min Technol 42(01):6–11 (in Chinese)

Jinxian W (2005) Multi sectional coal mining method applied to deep inclined thin seam and medium thick seam [J]. Coal Sci Techno 33(12):11–13 (in Chinese)

Li Fangli, Wu Yongping, Chen Jianjie, Xie Panshi. 2013 Research on fully mechanized technology by using large mining height method along longwall mining face in steeply dipping seam [R]. Wulumuqi: Xinjiang Tar Coal Group Co. Ltd, Xi’an: Xi’an University of Science and Technology, (in Chinese).

Hongchang L (1988) Similar simulation experiment of ground pressure [M]. China Mining University Press, Xuzhou (in Chinese)

Lian Y (2017) A photogrammetry program for physical modeling of subsurface subsidence process [D]. West Virginia University, Morgantown

Luo Y, Qiu B (2016) Enhanced subsurface subsidence prediction model that considers overburden stratification [J]. Min Eng 64(10):78–84

Funding

The authors acknowledge and appreciate technical support from Coal Mine No. 2130 of Xinjiang Coking Coal (Group) Co., Ltd. This work were supported by the National Natural Science Foundation of China [grant numbers: 51774230, 51634007 and 51604212], and Peak Project of Mining Engineering [grant number: 2018GG-2-07].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xie, P., Luo, Y., Wu, Y. et al. Roof Deformation Associated with Mining of Two Panels in Steeply Dipping Coal Seam Using Subsurface Subsidence Prediction Model and Physical Simulation Experiment. Mining, Metallurgy & Exploration 37, 581–591 (2020). https://doi.org/10.1007/s42461-019-00156-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-019-00156-x