Abstract

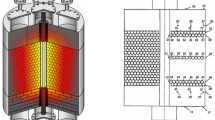

For designing and optimizing the reactor core of modular pebble-bed fluoride salt-cooled high-temperature reactor (PB-FHR), it is of importance to simulate the coupled fluid and particle flow due to strong coolant–pebble interactions. Computational fluid dynamics and discrete element method (DEM) coupling approach can be used to track particles individually while it requires a fluid cell being greater than the pebble diameter. However, the large size of pebbles makes the fluid grid too coarse to capture the complicated flow pattern. To solve this problem, a two-grid approach is proposed to calculate interphase momentum transfer between pebbles and coolant without the constraint on the shape and size of fluid meshes. The solid velocity, fluid velocity, fluid pressure and void fraction are mapped between hexahedral coarse particle grid and fine fluid grid. Then the total interphase force can be calculated independently to speed up computation. To evaluate suitability of this two-grid approach, the pressure drop and minimum fluidization velocity of a fluidized bed were predicted, and movements of the pebbles in complex flow field were studied experimentally and numerically. The spouting fluid through a central inlet pipe of a scaled visible PB-FHR core facility was set up to provide the complex flow field. Water was chosen as liquid to simulate the molten salt coolant, and polypropylene balls were used to simulate the pebble fuels. Results show that the pebble flow pattern captured from experiment agrees well with the simulation from two-grid approach, hence the applicability of the two-grid approach for the later PB-FHR core design.

Similar content being viewed by others

References

C.W. Forsberg, P.F. Peterson, P.S. Pickard et al., Molten-salt-cooled advanced high-temperature react or for production of hydrogen and electricity. Nucl. Technol. 144(3), 289–302 (2003). doi:10.13182/nt03-1

J. Serp, M. Allibert, O. Beneš et al., The molten salt reactor (MSR) in generation IV: overview and perspectives. Prog. Nucl. Energy 77, 308–319 (2014). doi:10.1016/j.pnucene.2014.02.014

R.O. Scarlat, M.R. Laufer, E.D. Blandford et al., Design and licensing strategies for the fluoride-salt-cooled, high-temperature reactor (FHR) technology. Prog. Nucl. Energy 77, 406–420 (2014). doi:10.1016/j.pnucene.2014.07.002

Z.J. Yang, J.L. Gou, J.Q. Shan et al., Analysis of SBLOCA on CPR1000 with a passive system. Nucl. Sci. Tech. (2016). doi:10.1007/s41365-016-0154-y

S. Bu, J. Yang, M. Zhou et al., On contact point modifications for forced convective heat transfer analysis in a structured packed bed of spheres. Nucl. Eng. Des. 270, 21–33 (2014). doi:10.1016/j.nucengdes.2014.01.001

H. Zhang, Y. Tan, S. Shu et al., Numerical investigation on the role of discrete element method in combined LBM–IBM–DEM modeling. Comput. Fluids 94, 37–48 (2014). doi:10.1016/j.compfluid.2014.01.032

H. Zhang, A. Yu, W. Zhong et al., A combined TLBM–IBM–DEM scheme for simulating isothermal particulate flow in fluid. Int. J. Heat Mass Transf. 91, 178–189 (2015). doi:10.1016/j.ijheatmasstransfer.2015.07.119

H. Kruggel-Emden, B. Kravets, M. Suryanarayana et al., Direct numerical simulation of coupled fluid flow and heat transfer for single particles and particle packings by a LBM-approach. Powder Technol. (2016). doi:10.1016/j.powtec.2016.02.038

Z. Xia, Y. Fan, T. Wang et al., A TFM-KTGF jetting fluidized bed coal gasification model and its validations with data of a bench-scale gasifier. Chem. Eng. Sci. 131, 12–21 (2015). doi:10.1016/j.ces.2015.03.017

L. Yu, J. Lu, X. Zhang et al., Numerical simulation of the bubbling fluidized bed coal gasification by the kinetic theory of granular flow (KTGF). Fuel 86(5), 722–734 (2007). doi:10.1016/j.fuel.2006.09.008

H. Zhu, Z. Zhou, R. Yang et al., Discrete particle simulation of particulate systems: theoretical developments. Chem. Eng. Sci. 62(13), 3378–3396 (2007). doi:10.1016/j.ces.2006.12.089

J. Vujić, R.M. Bergmann, R. Škoda et al., Small modular reactors: simpler, safer, cheaper? Energy. 45(1), 288–295 (2012). doi:10.1016/j.energy.2012.01.078

Y. Li, W. Ji, Effects of fluid–pebble interactions on mechanics in large-scale pebble-bed reactor cores. Int. J. Multiphas. Flow. 73, 118–129 (2015). doi:10.1016/j.ijmultiphaseflow.2015.03.004

S. Deb, D.K. Tafti, A novel two-grid formulation for fluid–particle systems using the discrete element method. Powder Technol. 246, 601–616 (2013). doi:10.1016/j.powtec.2013.06.014

F. Alobaid, J. Ströhle, B. Epple et al., Extended CFD/DEM model for the simulation of circulating fluidized bed. Adv. Powder Technol. 24(1), 403–415 (2013). doi:10.1016/j.apt.2012.09.003

F. Alobaid, A particle–grid method for Euler-Lagrange approach. Powder Technol. 286, 342–360 (2015). doi:10.1016/j.powtec.2015.08.019

S. Rickelt, F. Sudbrock, S. Wirtz et al., Coupled DEM/CFD simulation of heat transfer in a generic grate system agitated by bars. Powder Technol. 249, 360–372 (2013). doi:10.1016/j.powtec.2013.08.043

C. Goniva, C. Kloss, A. Hager et al., An open source CFD-DEM perspective. Proceedings of Open FOAM Workshop(2010)

P.A. Cundall, O.D. Strack, A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979). doi:10.1680/geot.1979.29.1.47

J. Su, Z. Gu, C. Chen et al., A two-layer mesh method for discrete element simulation of gas-particle systems with arbitrarily polyhedral mesh. Int. J. Numer. Methods Eng. 103(10), 759–780 (2015). doi:10.1002/nme.4911

A. Fabri, S. Pion,CGAL: The computational geometry algorithms library. In Proceedings of the 17th ACM SIGSPATIAL International Conference on Advances in Geographic Information Systems. ACM (2009). doi: 10.1145/1653771.1653865

Z. Peng, E. Doroodchi, C. Luo et al., Influence of void fraction calculation on fidelity of CFD-DEM simulation of gas-solid bubbling fluidized beds. AIChE J. 60(6), 2000–2018 (2014). doi:10.1002/aic.14421

S. Ergun, Fluid flow through packed columns. J. Ind. Eng. Chem. 41, 1179–1184 (1949). doi:10.1021/ie50474a011

A. Griveau, Modeling and Transient Analysis for the Pebble Bed Advanced High Temperature Reactor ~ PB-AHTR,Master. Thesis, University of California, Berkeley (2007)

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the “Strategic Priority Research Program” of the Chinese Academy of Sciences (No. XD02001002)

Rights and permissions

About this article

Cite this article

Liu, FR., Chen, XW., Li, Z. et al. DEM–CFD simulation of modular PB-FHR core with two-grid method. NUCL SCI TECH 28, 100 (2017). https://doi.org/10.1007/s41365-017-0246-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-017-0246-3