Abstract

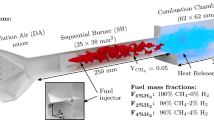

The demand for energy grows along with the number of studies in the field of alternative energy. Clean energy has been the goal of numerous studies and it has been encouraged, seen by the gradual migration from conventional to hybrid or purely electric vehicles. Although clean energy is desirable, we continue to rely on traditional fuel. Thus, this work aims to improve the efficiency and minimize the polluting effects of the fuels in internal combustion engines. Using the combustion mode of reactivity-controlled compression ignition, in which two different fluids, with distinct auto-ignition characteristics, are injected into the combustion chamber, at different times, aiming to burn the fuel at a lower power of auto-ignition. Parameters such as the amount of fuel and start of injections points (SOIs) have substantial influence on the overall process. Performance, emissions, combustion noise and others characteristics are mainly influenced by the ignition delay. The ignition delay in a diesel engine is defined as the interval of time between the start of fuel injection and the combustion. Therefore, with the SOI of the fuel with lower enthalpy of vaporization and the start of combustion, the ignition delay can be inferred. The results show the influence of different parameters, such as compression ratio, start of fuel injections, injection strategies of two different fuels, in this case, hydrous ethanol and diesel, on the combustion process. The results are presented for compression ratios of 16:1 and 20:1.

Similar content being viewed by others

References

Ometto A (2005) Life cycle assessment of hydrous ethylic alcohol fuel by EDIP, exergy and emergy methods. Ph.D thesis—Escola de Engenharia de So Carlos, Universidade de São Paulo

Goldenstein M, Azevedo R (2006) Alternative fuels and innovation in automotive sector: the end of “Age of Oil”? BNDES 23:235–266

Schaefer A, Hardenberg H (1981) Ignition improvers for ethanol fuels. SAE Technical Paper 810249. doi:10.4271/810249

Dickerson M (2005, June 17) Brazil’s ethanol effort helping lead to oil self- sufficiency. The Seattle Times

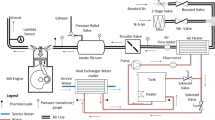

Sánchez F, Braga C, Braga L, Braga S. et al. (2013) Ethanol-powered combustion experimental study in a rapid compression machine. SAE Technical Paper 2013-36-0313. doi:10.4271/2013-36-0313

Yilmaz N, Donaldson A, Johns A (2005) Some perspectives on alcohol utilization in a compression ignition engine. SAE Technical Paper 2005-01-3135. doi:10.4271/2005-01-3135

Simonsen H, Chomiak J (1995) Testing and evaluation of ignition improvers for ethanol in a DI diesel engine. SAE Technical Paper 952512. doi:10.4271/952512

Valdez J (2014) Reactivity controlled compression ignition of diesel fuel and ethanol in rapid compression machine. Ph.D thesis, Departamento de Engenharia Mecânica, Pontifical Catholic University of Rio de Janeiro, Rio de Janeiro

Egúsquiza CJC (2011) Experimental investigation of a diesel cycle engine operating on dual-fuel mode: diesel/ethanol and diesel/gas. Ph.D thesis, Departamento de Engenharia Mecânica, Pontifical Catholic University of Rio de Janeiro, Rio de Janeiro

Kokjohn S, Hanson R, Splitter D, Kaddatz J et al (2011) Fuel reactivity controlled compression ignition (rcci) combustion in light and heavy - duty engines. SAE Int J Engines 4(1):360–374. doi:10.4271/2011-01-0357

Splitter D, Reitz R, Hanson R (2010) High efficiency, low emissions RCCI combustion by use of a fuel additive. SAE Int J Fuels Lubr 3(2):742–756. doi:10.4271/2010-01-2167

Curran S, Hanson R, Barone T, Storey J et al. (2012) Performance of advanced combustion modes with alternative fuels: reactivity controlled compression ignition case study. Energy & Transportation Science Division Oak Ridge National Laboratory, CBES Forum

Jayaraman S (2012) Performance optimization of a diesel engine for dual—fuel combustion. M.Sc. thesis, The Graduate School College of Engineering, The Pennsylvania State University, State College

Heywood J (1988) Internal combustion engine fundamentals, 1st edn. Mc Graw- Hill Book Company, New York

Zou H, Wang L, Liu S, Li Y (2008) Ignition delay of dual fuel engine operating with methanol ignited by pilot diesel. Front Energy 2(3):285–290. doi:10.1007/s11708-008-0060z

Reddy P, Krishna D, Mallan K, Ganesan V (1993) Evaluation of combustion parameters in direct injection diesel engines—an easy and reliable method. SAE Technical Paper 930605. doi:10.4271/930605

Shahabuddin M et al (2013) Ignition delay, combustion and emission characteristics of diesel engine fueled with biodiesel. Renew Sustain Energy Rev 21:623–632

Da Silva E, Trres R (2013) Thermophysical properties of diesel/biodiesel blends. In: 22nd international congress of mechanical engineering (COBEM 2013), São Paulo, pp 6577–6584

Villela A, Machado G (2012) Multifuel engine performance, emissions and combustion using anhydrous and hydrous ethanol. SAE Technical Paper 2012-36-0475. doi:10.4271/2012-36-0475

Turkan A, Canakci M (2011) Combustion characteristics of an indirect injection (IDI) diesel engine fueled with ethanol/diesel and methanol/diesel blends at different injection timings. World Renew Energy Cong 1:3565–3572

Bodisco T, Brown R (2013) Inter-cycle variability of in-cylinder pressure parameters in an ethanol fumigated common rail diesel engine. Energy 52:55–65. doi:10.1016/j.energy.2012.12.032

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Francisco Ricardo Cunha.

Rights and permissions

About this article

Cite this article

Loaiza, J.C.V., Sánchez, F.Z. & Braga, S.L. Combustion study of reactivity-controlled compression ignition (RCCI) for the mixture of diesel fuel and ethanol in a rapid compression machine. J Braz. Soc. Mech. Sci. Eng. 38, 1073–1085 (2016). https://doi.org/10.1007/s40430-015-0400-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-015-0400-y