Abstract

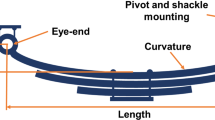

The term symmetrical multi-leaf spring is generally applied to springs of constant width, properly stepped leaves and each leaf of constant thickness and equal cantilever lengths. The main leaf is under the action of longitudinal and lateral forces during its operation, hence it is not desired that the maximum stress is induced in it. To reduce this stress, leaves with different unassembled cambers are assembled by pulling against each other and a common curvature is established. This causes stress concentration or set assembly stress in the assembled leaf springs. The assembly stress is subtractive from load stress in the master leaf, while it is additive to load stress in short leaves. It is possible to distribute the stress in a desirable manner among the leaves by a suitable combination of assembly stresses and stepping. The work presented in this article provides a design procedure for the number of leaves, stepping, individual leaf camber and no load assembly camber of leaf springs used in a light commercial vehicle. A proper combination of stepping and camber has been proposed by taking leaf spring design parameters into consideration, so that the stress in the leaves does not exceed maximum design stress. The leaf springs with the proposed parameters have been manufactured and tested on a full-scale leaf spring testing machine. The analytical stepping, no load assembly camber and individual leaf camber were compared with actual leaf spring for validation.

Similar content being viewed by others

Abbreviations

- C a :

-

No load assembly camber

- C at :

-

Actual no load assembly camber

- C l :

-

Individual leaf camber

- q o :

-

No load assembly curvature

- q n :

-

Individual leaf curvature

- R l :

-

Free radius for individual leaf

- R a :

-

No load assembly radius

- S t :

-

Total stress

- S l :

-

Load stress

- S a :

-

Assembly stress

- S d :

-

Stress at design load without assembly stress

- S m :

-

Stress at maximum load without assembly stress

- S da :

-

Stress at design load with assembly stress

- S ma :

-

Stress at maximum load with assembly stress

- S fa :

-

Stress on the front cantilever

- S rb :

-

Stress on the rear cantilever

References

Fuentes JJ, Agulilar HJ, Rodriguez JA, Herrera EJ (2008) Premature fracture in automobile leaf springs. Eng Fail Anal 16(2):648–665

Aggarwal ML, Agarwal VP, Khan RA (2006) A stress approach model for predicting fatigue life of shot peened EN45A spring steel. Int J Fatigue 28(12):1845–1853

Aggarwal ML, Chawla PS (2006) Optimization of micro welds used in leaf springs. Indian J Eng Mater Sci 13(3):217–220

Saelem S, Chantranuwathana S, Panichanun K, Preedanood P, Wichienprakarn P, Kruo-ongarjnukool P (2009) Experimental verification of leaf spring model by using a leaf spring test rig. In: 23rd conference of mechanical engineering network of Thailand

IS 1135 (1995) Springs—leaf springs assembly for automobiles

Norton RL (2001) Machine design—an integrated approach, 2nd edn. Pearson Education, Hong Kong, pp 366–383

Spring Design Manual (1990) Design and application of leaf springs, HS-744, AE-11, Society of Automotive Engineers

Acknowledgments

I would like to acknowledge Mr. P S Chawla and the leaf springs testing division of Friends Auto (India) Ltd., and especially Mr. M. K. Gupta whose unconditional support has made this project successful.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Fernando Antonio Forcellini.

Rights and permissions

About this article

Cite this article

Arora, V.K., Bhushan, G. & Aggarwal, M.L. Precise estimation of individual leaf camber and stepping in symmetrical 65Si7 leaf springs. J Braz. Soc. Mech. Sci. Eng. 38, 1717–1729 (2016). https://doi.org/10.1007/s40430-015-0396-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-015-0396-3