Abstract

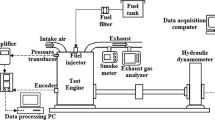

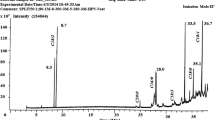

The current work is aimed at the correlated multiple criteria optimization of various parameters of a turbocharged, direct injection, compression ignition engine alternatively fuelled with neat biodiesel and its 20 % blend with commercial diesel (B20) using grey–Taguchi method (GTM). The GTM converts multiple objectives of a problem into a single-objective function by an optimization technique. The process environment consisting of three input variables such as type of fuel, engine speed, and load was considered in this study. An orthogonal array was used for the design of experiments on the basis of L9 (33). The optimal parameters were determined by the grey relational grade based on GTM. The consequent optimal combination of input parameters was used to maximize the output parameters including engine torque, brake power, heat release, and injection pressure with the possible diminution of brake specific fuel consumption of the engine. During the study, it was found that B20 as a fuel, 1,800 rpm as a speed, and 100 % as a load offer an optimal parametric combination at which the desired output results are achieved. Moreover, analysis of variance approach based on statistical software of Minitab 16 was used to investigate the comparative impacts of input variables on the output responses. It was known that load is the predominant factor with an influence of 92.42 % on the output parameters. Finally, a confirmatory test was performed to validate the results using artificial neural network in MATLAB.

Similar content being viewed by others

Abbreviations

- CI:

-

Compression ignition

- DI:

-

Direct injection

- H.R:

-

Heat release

- IP:

-

Injection pressure

- BSFC:

-

Brake specific fuel consumption

- DOE:

-

Design of experiments

- OA:

-

Orthogonal array

- GRA:

-

Grey relational analysis

- GRG:

-

Grey relational grade

- OGRG:

-

Overall grey relational grade

- GRC:

-

Grey relational coefficient

- QLF:

-

Quality loss function

- ANOVA:

-

Analysis of variance

- DOF:

-

Degree of freedom

- ANN:

-

Artificial neural network

References

Ozener O, Yuksek L, Ergenç AT, Ozkan M (2014) Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 115:875–883. doi:10.1016/j.fuel.2012.10.081

Turrio-Baldassarri L, Battistelli CL et al (2004) Emission comparison of urban bus engine fueled with diesel oil and biodiesel blend. Sci Total Environ 327:147–162. doi:10.1016/j.scitotenv.2003.10.033

Monyem A, Van Gerpen JH (2001) The effect of biodiesel oxidation on engine performance and emission. Biomass Bioenergy 20:317–325. doi:10.1016/S0961-9534(00)00095-7

Buyukkaya E (2010) Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 89:3099–3105. doi:10.1016/j.fuel.2010.05.034

Agarwal D, Agrawal AK (2007) Performance and emission characteristics of a jatropha oil (preheated and blends) in a direct injection compression ignition engine. Appl Therm Eng 27:2314–2323. doi:10.1016/j.applthermaleng.2007.01.009

Ramadhas AS, Muraleedharan C, Jayaraj S (2005) Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil. Renew Energy 30:1789–1800. doi:10.1016/j.renene.2005.01.009

Durbin T, Collins J, Norbeck J, Smith M (2000) Effects of biodiesel, biodiesel blends, and a synthetic diesel on emissions from light heavy-duty diesel vehicles. Environ Sci Technol 34:349–355. doi:10.1021/es990543c

Agarwal D, Kumar L, Agarwal AK (2008) Performance evaluation of a vegetable oil fuelled compression ignition engine. Renew Energy 33:1147–1156. doi:10.1016/j.renene.2007.06.017

Hammond G, Kallu S, McManus M (2008) Development of biofuels for the UK automotive market. Appl Energy 85:506–515

Banapurmath NR, Tewari PG, Hosmath RS (2008) Performance and emission characteristics of DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters. Renew Energy 33:1982–1988. doi:10.1016/j.renene.2007.11.012

Ganapathy T, Murugesan K, Gakkhar RP (2009) Performance optimization of jatropha engine model using Taguchi approach. Appl Energy 86:2476–2486. doi:10.1016/j.apenergy.2009.02.008

Yang WH, Tarng YS (1998) Design optimization of cutting parameters for turning operations based on the Taguchi method. J Mater Process Technol 84:122–129. doi:10.1016/S0924-0136(98)00079-X

Mehat NM, Kamaruddin S (2012) Quality control and design optimisation of plastic product using Taguchi method: a comprehensive review. Int J Plast Technol 16:194–209. doi:10.1007/s12588-012-9037-1

Martowibowo SY, Wahyudi A (2012) Taguchi method implementation in taper motion wire EDM process optimization. J Inst Eng India Ser C 93:357–364. doi:10.1007/s40032-012-0043-z

Lin CL (2004) Use of the Taguchi method and grey relational analysis to optimize turning operations with multiple performance characteristics. Mat Manuf Pro 2:209–220. doi:10.1081/AMP-120029852

Pal S, Malviya SK, Pal SK, Samantaray AK (2009) Optimization of quality characteristics parameters in a pulsed metal inert gas welding process using grey-based Taguchi method. Int J Adv Manuf Technol 44:1250–1260. doi:10.1007/s00170-009-1931-0

Jung JH, Kwon WT (2010) Optimization of EDM process for multiple performance characteristics using Taguchi method and grey relational analysis. J Mech Sci Technol 24:1083–1090. doi:10.1007/s12206-010-0305-8

Zeng S, Xiong Y (2012) Application of Grey based Taguchi method to determine optimal end milling parameters. Intell Robot Appl 7507:245–254. doi:10.1007/978-3-642-33515-0_25

Lin JL, Lin CL (2002) The use of the orthogonal array with the grey relational analysis to optimize the electrical discharge machining process with multiple performance characteristics. Int J Mach Tool Manuf 42:237–244

Ko TC, Fu PC (2006) Optimization of the WEDM process of particle reinforced material with multiple performance characteristics using grey relational analysis. J Mater Process Technol 180:96–101

Lung KP, Wang CC et al (2007) Optimizing multiple quality characteristics via Taguchi method based grey analysis. J Mater Process Technol 182:107–116

Li CH, Tsai MJ (2009) Multi objective optimization of laser cutting for flash memory modules with special shapes using grey relational analysis. Opt Laser Technol 41:634–642

Tsai MJ, Li CH (2009) The use of grey relational analysis to determine laser cutting parameters for QFN packages with multiple performance characteristics. Opt Laser Technol 41:914–921

Chorng JT, Yung et al (2009) Optimization of turning operations with multiple performance characteristics using the Taguchi method and grey relational analysis. J Mat Pro Technol 209:2753–2759

Roy S, Das AK, Banerjee R (2014) Application of Grey-Taguchi based multi-objective optimization strategy to calibrate the PM–NHC–BSFC trade-off characteristics of a CRDI assisted CNG dual-fuel engine. J Nat Gas Sci Eng 21:524–531. doi:10.1016/j.jngse.2014.09.022

Karnwal A, Hasan MM, Kumar N, Siddiquee AN, Khan ZA (2011) Multi-response optimization of diesel engine performance parameters using Thumba biodiesel—diesel blends by applying the Taguchi method and grey relational analysis. Int J Automot Technol 12:599–610. doi:10.1007/s12239-011-0070-4

Muralidharan K, Vasudevan D (2014) Applications of artificial neural networks in prediction of performance, emission and combustion characteristics of variable compression ratio engine fuelled with waste cooking oil biodiesel. Soc Mech Sci Eng, J Braz. doi:10.1007/s40430-014-0213-4

Su CT, Chiang TL (2003) Optimizing the IC wire bonding process using a neural networks genetic algorithms approach. J Intelli Manuf 14:229–238

Kannan GR, Balasubramanian KR, Anand R (2013) Artificial neural network approach to study the effect of injection pressure and timing on diesel engine performance fueled with biodiesel. Int J Auto Tech 14:507–519. doi:10.1007/s12239-013-0055-6

Gau HS, Hsieh CY, Liu CW (2006) Application of grey correlation method to evaluate potential groundwater recharge sites. Stoch Environ Res Risk Assess 20:407–421. doi:10.1007/s00477-006-0034-9

Tsolakis A (2006) Effects on particle size distribution from the diesel engine operating on RME-biodiesel with EGR. Energy Fuels 20:1418–1424. doi:10.1021/ef050385c

Acherjee B, Kuar AS, Mitra S, Misra D (2011) Application of grey-based Taguchi method for simultaneous optimization of multiple quality characteristics in laser transmission welding process of thermoplastics. Int J Adv Manuf Technol 56:995–1006. doi:10.1007/s00170-011-3224-7

Jailani HS, Rajadurai A, Mohan B, Kumar AS, Sornakumar T (2009) Multi-response optimisation of sintering parameters of Al–Si alloy/fly ash composite using Taguchi method and grey relational analysis. Int J Adv Manuf Technol 45:362–369. doi:10.1007/s00170-009-1973-3

Raza ZA, Ahmad N, Kamal S (2014) Multi-response optimization of rhamnolipid production using grey rational analysis in Taguchi method. Biotechnol Rep 3:86–94

Wijayasekara D, Manic M, Sabharwall P, Utgikar V (2011) Optimal artificial neural network architecture selection for performance prediction of compact heat exchanger with the EBaLM-OTR technique. Nucl Eng Des 241:2549–2557. doi:10.1016/j.nucengdes.2011.04.045

Ghobadian B, Rahimi H, Nikbakht AM, Najafi G, Yusaf TF (2009) Diesel engine performance and exhaust emission analysis using waste cooking biodiesel fuel with an artificial neural network. Renew Energy 34:976–982. doi:10.1016/j.renene.2008.08.008

Huang JT, Liao YS (2003) Optimization of machining parameters of wire-EDM based on grey relational and statistical analyses. Int J Prod Res 41:1707–1720. doi:10.1080/1352816031000074973

Rao R, Yadava V (2009) Multi-objective optimization of Nd:YAG laser cutting of thin superalloy sheet using Grey relational analysis with entropy measurement. Opt Laser Technol 41:922–930. doi:10.1016/j.optlastec.2009.03.008

Yang YS, Shih CY, Fung RF (2014) Multi-objective optimization of the light guide rod by using the combined Taguchi method and grey relational approach. J Intell Manuf 25:99–107. doi:10.1007/s10845-012-0678-x

Maiyar LM, Ramanujam R, Venkatesan K, Jerald J (2013) Optimization of machining parameters for end milling of Inconel 718 super alloy using Taguchi based grey relational analysis. Proced Eng 64:1276–1282. doi:10.1016/j.proeng.2013.09.208

Tzeng CJ, LinYH YangYK, Jeng MC (2009) Optimization of turning operations with multiple performance characteristics using the Taguchi method and grey relational analysis. J Mater Process Technol 209:2753–2759. doi:10.1016/j.jmatprotec.2008.06.046

Manjunath Patel GC, Krishna P, Parappagoudar MB (2014) Optimization of squeeze cast process parameters using Taguchi and grey relational analysis. Proced Technol 14:157–164. doi:10.1016/j.protcy.2014.08.021

Tarng YS, Juang SC, Chang CH (2002) The use of grey-based Taguchi methods to determine submerged arc welding process parameters in hardfacing. J Mater Process Technol 128:1–6. doi:10.1016/S0924-0136(01)01261-4

Acknowledgments

Authors are indebted to Dr. Ge and Dr. Tan for their guidelines and encouraging attitude, and the lab staff for their help in the conduct of experiments. The experiments were performed in the Laboratory of Auto Performance and Emission Test. School of Mechanical and Vehicular Engineering, Beijing Institute of Technology, Beijing 100081, P. R. China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Luis Fernando Figueira da Silva.

Rights and permissions

About this article

Cite this article

Gul, M., Shah, A.N., Jamal, Y. et al. Multi-variable optimization of diesel engine fuelled with biodiesel using grey-Taguchi method. J Braz. Soc. Mech. Sci. Eng. 38, 621–632 (2016). https://doi.org/10.1007/s40430-015-0312-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-015-0312-x